Flexible hole expanding device and method

A flexible and reaming seat technology, which is applied in drilling equipment and methods, earthwork drilling, construction, etc., can solve the problems of easy fatigue damage, high stress, and affecting drilling retreat, so as to improve reaming efficiency and reduce reaming Cost, the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

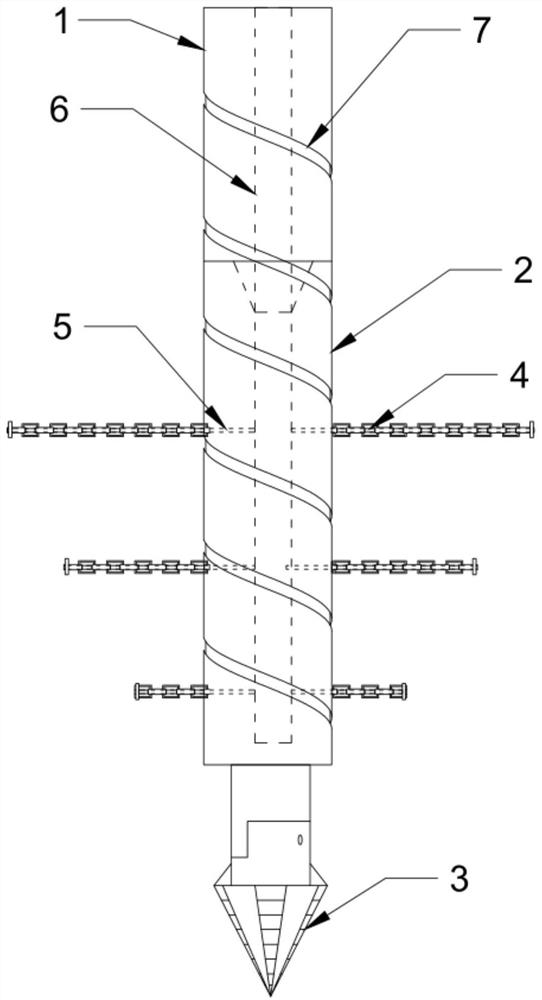

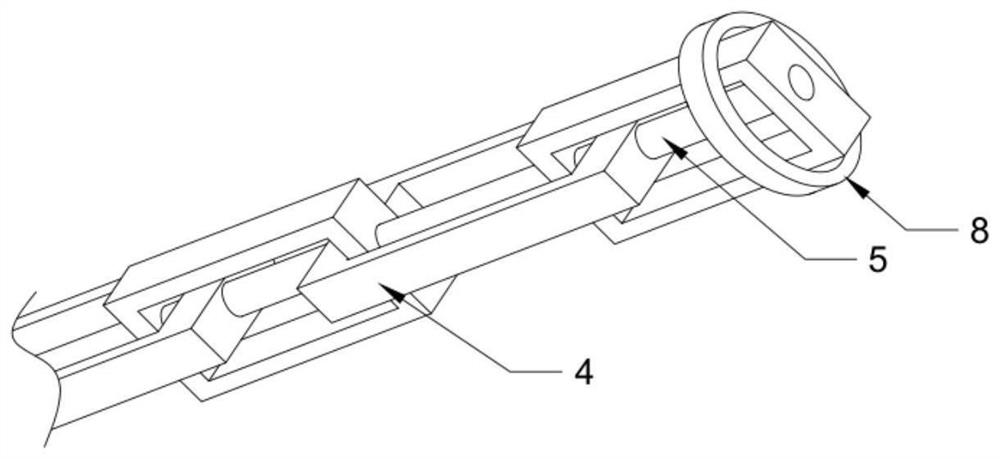

[0026] like Figure 1~2 As shown, the present invention provides a flexible reaming device, comprising a drill rod 1, a reaming seat 2 and a drill bit 3, the two ends of the reaming seat 2 are respectively connected with the drill bit 3 and the drill rod 1, and the drill The end of the rod 1 far away from the reaming seat 2 is connected to the reduction motor (not shown in the figure), and the reaming seat 2 is provided with a flexible reaming chain 4, and the flexible reaming chain 4 is made of high-strength wear-resistant metal material , the high-strength wear-resistant metal material is selected from 27SiMn material. And the flexible reaming chain 4 is pierced with a high-pressure hose 5, the drill pipe 1 and the reaming seat 2 are provided with a high-pressure water channel 6 connected to each other, and the high-pressure hose 5 communicates with the high-pressure water channel 6. One end of the high-pressure hose 5 away from the reaming seat 2 is open or closed. The fl...

Embodiment 2

[0029] like Figure 1~2 As shown, the present invention also provides a flexible hole reaming method based on the flexible hole reaming device described in Embodiment 1, comprising the following steps:

[0030] 1) Drilling positioning: measure and set out the line according to the coal seam conditions to locate the drilling position;

[0031] 2) Drilling: First, use an ordinary gas drainage drilling rig to drill an ordinary hole through the rock layer to the coal seam. The diameter of the ordinary hole is 113mm. Stop drilling when the depth of the ordinary hole reaches the designed position, and withdraw the ordinary bit;

[0032]3) Reaming: Put the reaming seat 2 of the flexible reaming device into the coal seam through the rock layer along the ordinary drill hole, start the deceleration motor, drive the drill pipe 1 to rotate, and make the flexible reaming chain 4 swing under the action of inertia , in order to improve the cutting strength of the flexible reaming chain 4 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com