Conductive ink comprising diacetylene diol monomer and conductive polymer, and method for producing micropattern by using same

A technology of conductive polymers and conductive inks, applied in the direction of inks, conductive materials, conductive materials, etc., can solve the problems of increased surface resistance, difficult to transparent electrodes, etc., and achieve the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1-9

[0098] 2,4-Hexadiyn-1,6-diol (HDO) was added to 1 g of PEDOT:PSS aqueous solution (Sigma-Aldrich) including 0.5% by weight of PEDOT and 0.8% by weight of PSS as shown in Table 1, and ultrasonically It was fully dissolved for 10 minutes to obtain a mixed solution. The mixed solution was filtered using a 0.45 mm filter to remove impurities to obtain conductive ink compositions for optical micromachining according to Preparation Examples 1-9.

[0099] Table 1

[0100]

[0101]

preparation Embodiment 10-12

[0103] In addition to using 6.5mg 3,5-octadiyne-1,8-diol (composition preparation example 10), 6.5mg 4,6-decadiyn-1,10-diol (composition preparation example 11 ) or 6.5 mg of 5,7-dodecadiyne-1,12-diol (composition preparation example 12) instead of 6.5 mg of 2,4-hexadiyne-1,6-diol (HDO) , A composition was prepared in the same manner as in Preparation Example 6.

[0104] Examples of Micropattern Preparation

preparation Embodiment 1

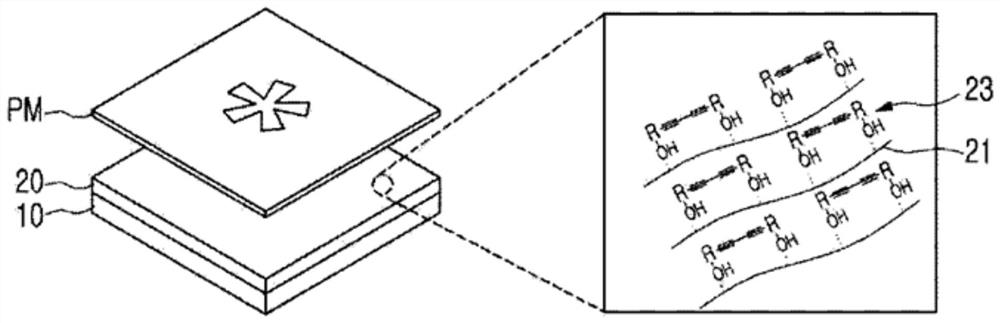

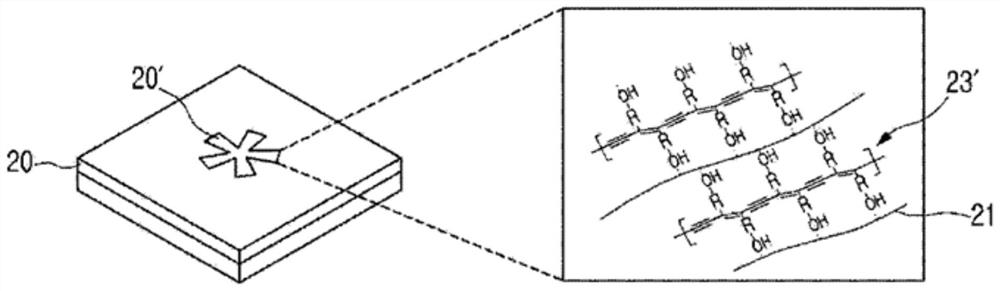

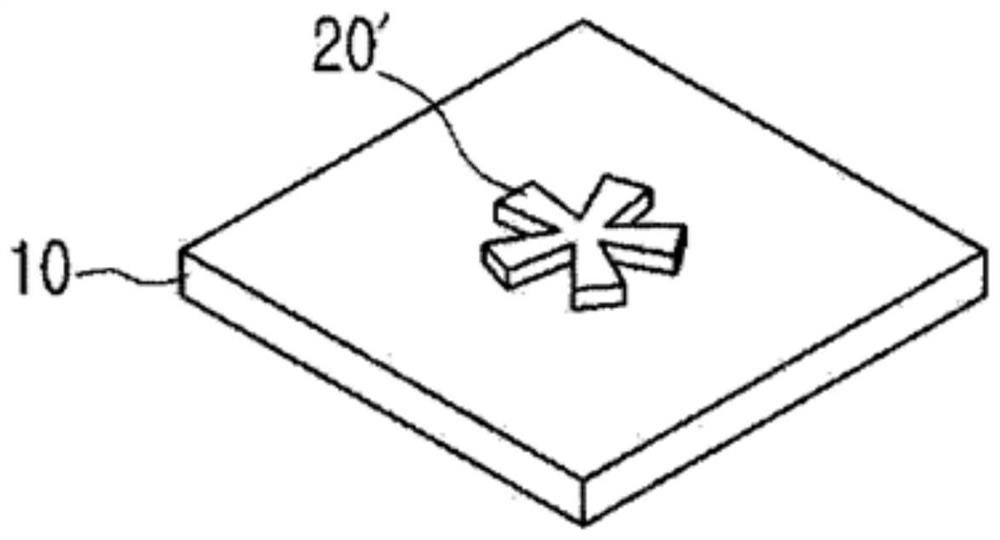

[0106] One of the prepared conductive ink compositions was spin-coated on a glass substrate to obtain a uniform conductive film, and then dried to measure the conductivity of the conductive film. A photomask with a light-transmitting pattern is arranged on the conductive film, and the photomask is used as a mask to irradiate a wavelength of 254nm (12.5mWcm -2 ) of ultraviolet light for 10 seconds. After the UV exposure, the substrate with the conductive film was immersed in water to remove the portion not irradiated by UV, and then washed with ethanol to form a conductive pattern. Then, the conductive pattern was dried, and the conductivity of the dried conductive pattern was measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com