Low-speed permanent magnet synchronous motor direct-driven variable-frequency speed-regulating ore grinding equipment

A permanent magnet synchronous motor, frequency conversion speed regulation technology, applied in the direction of magnetic circuit, electromechanical device, electrical components, etc., can solve the problems of non-adjustable equipment running speed, low reliability of equipment operation, and many transmission connectors, etc., and achieve reduction Effects of operating cost, reduction of maintenance workload, and optimization of operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

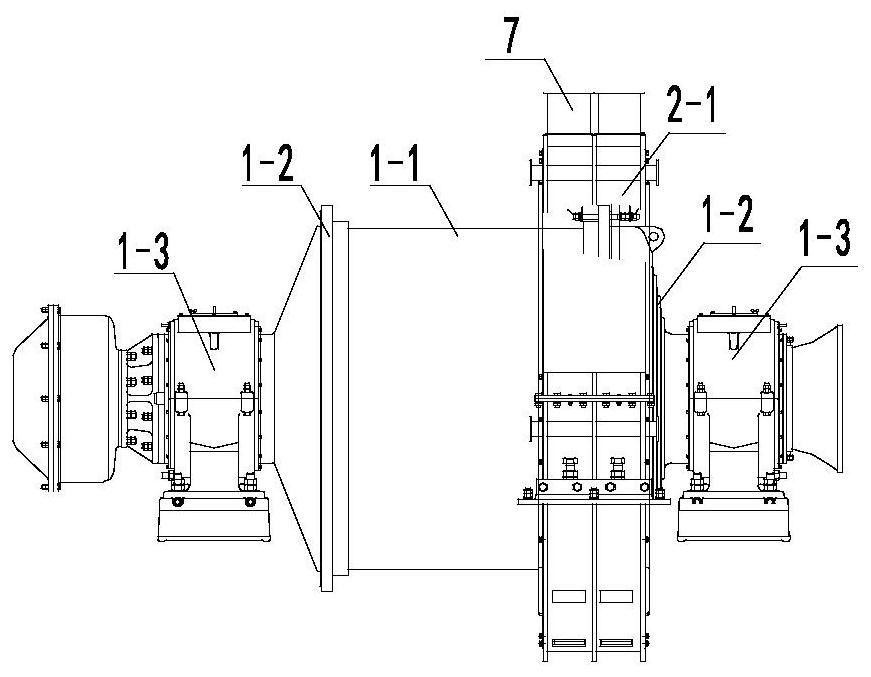

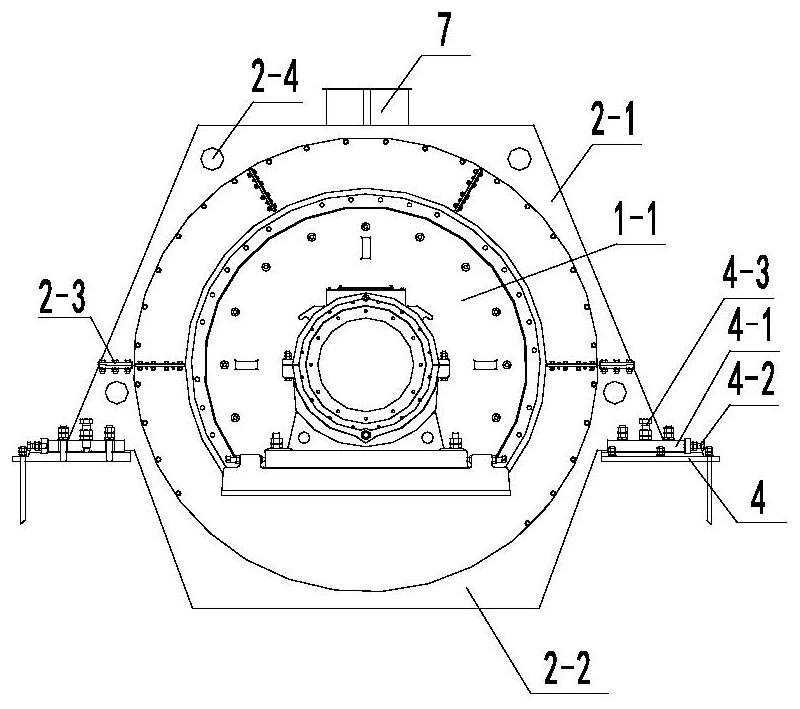

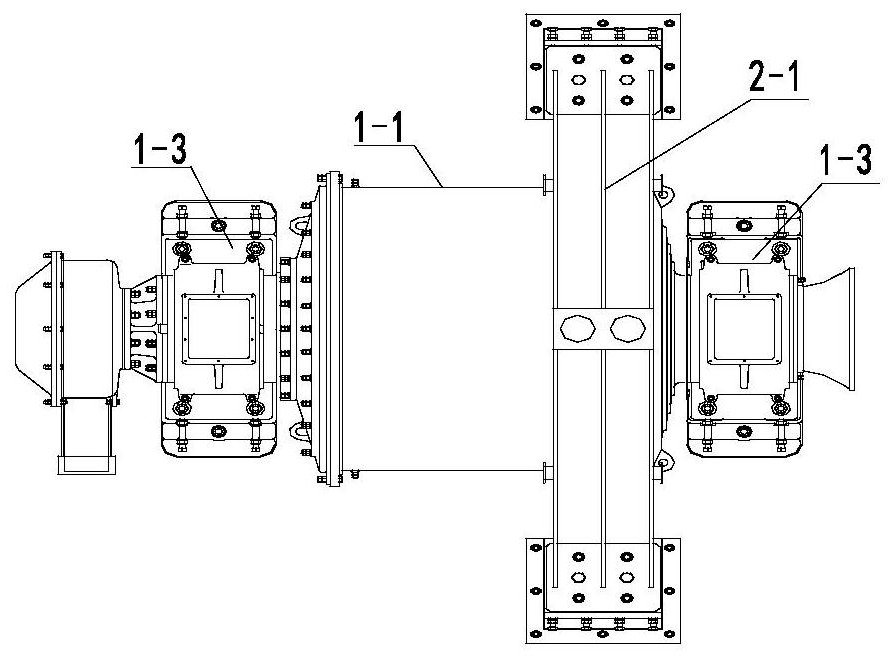

[0023] like figure 1 , figure 2 , image 3 As shown, a low-speed permanent magnet synchronous motor direct drive frequency conversion speed regulation grinding equipment, including grinding equipment, a low speed permanent magnet synchronous motor that drives the grinding cylinder of the grinding equipment to rotate 1-1 and its frequency conversion speed regulation control system . The two ends of the grinding cylinder body 1-1 of the grinding equipment are installed on the drum support 1-3.

[0024] like Figure 5 As shown, the rotor of the low-speed permanent magnet synchronous motor is composed of a semicircular rotor upper lobe 3-1 and a semicircular rotor lower lobe 3-2 that can form a ring, and the rotor upper lobe and the rotor lower lobe There are extended lap strips on the mating surfaces, and connection holes are opened on the lap strips...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com