Tool clamp of motor end cover capable of alternately working

A technology of motor end cover and tooling fixture, which is applied in the direction of manufacturing tools, metal processing machinery parts, metal processing equipment, etc., can solve the problem of inconvenient clamping of motor end cover, and achieve simple structure, convenient clamping and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

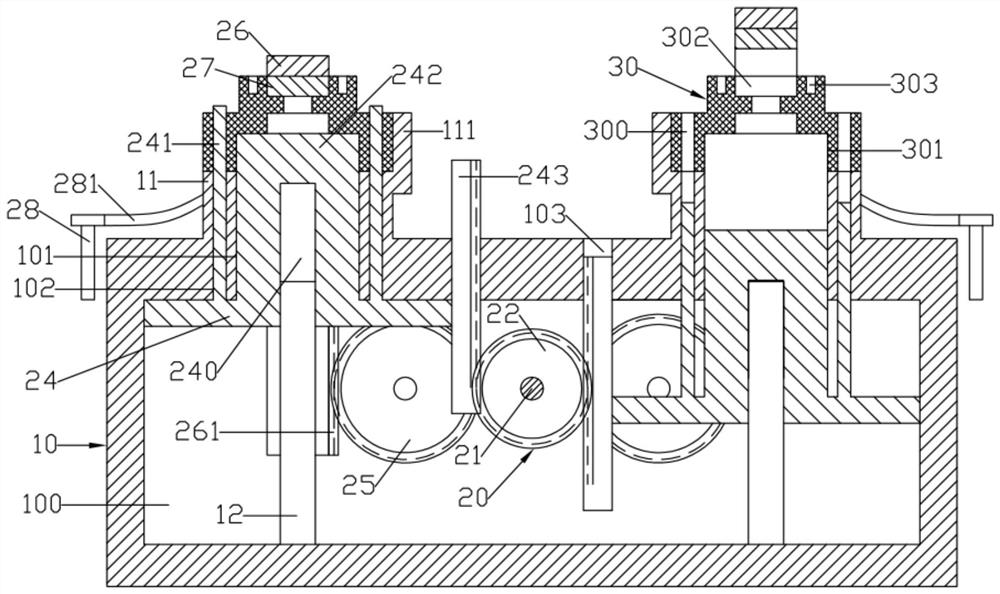

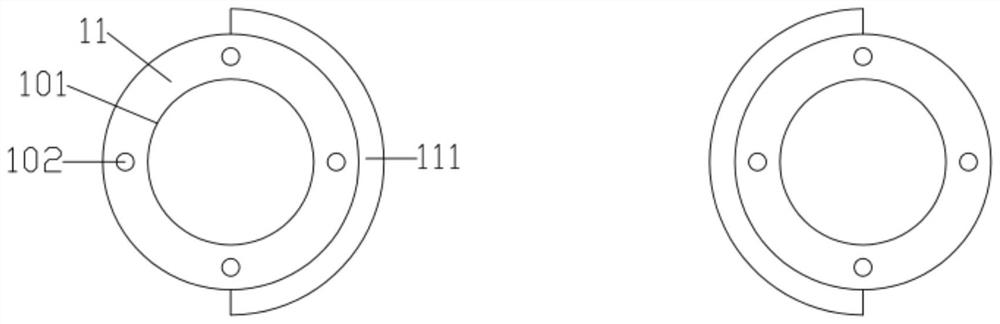

[0014] Such as figure 1 , figure 2 As shown, a tooling fixture of an alternately working motor end cover includes a rectangular parallelepiped support base 10 and an alternate limiter 20; the inside of the support base 10 is formed with a rectangular groove-shaped drive slot 100; There is a pair of symmetrically arranged cylindrical placement bases 11 on the top; a round hole-shaped central lifting hole 101 is formed in the center of the upper end surface of the placement base 11; Distributed downward penetrating circular hole-shaped limit column lifting holes 102; one end of the outer cylindrical surface of a pair of placement bases 11 that is close to each other is formed with a semi-circular cylindrical blocking ring 111; the alternate limit device 20 includes a The lifting support plate 24 that lifts is provided with and the upper limit seat 26 of " 凵 " font that the opening of a pair of lifts is provided with downwards is provided with; The cylindrical central limit co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com