Environment friendly quick-drying water-based ink printing process

A water-based ink, environmental protection technology, applied in printing, ink, printing device, etc., can solve the problems of complicated process, low printing efficiency, increased labor cost, etc., achieve simple and convenient preparation process, improve printing efficiency, and reduce labor cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] First, explain the original intention of the present invention. The existing packaging products need to be printed, and most of the printing processes are ink printing. The existing ordinary inks are adjusted before printing. When printing four-color multi-color products, deinking often occurs. As a result, the quality of printed products cannot meet the requirements. In order to ensure the quality requirements of printed products, manual auxiliary printing is required, which increases the printing cost of the enterprise. Secondly, ordinary inks will fail due to overheating or chemical protection layer decomposition during the processing process. For this reason, the present invention provides an environmentally friendly and quick-drying water-based ink printing process.

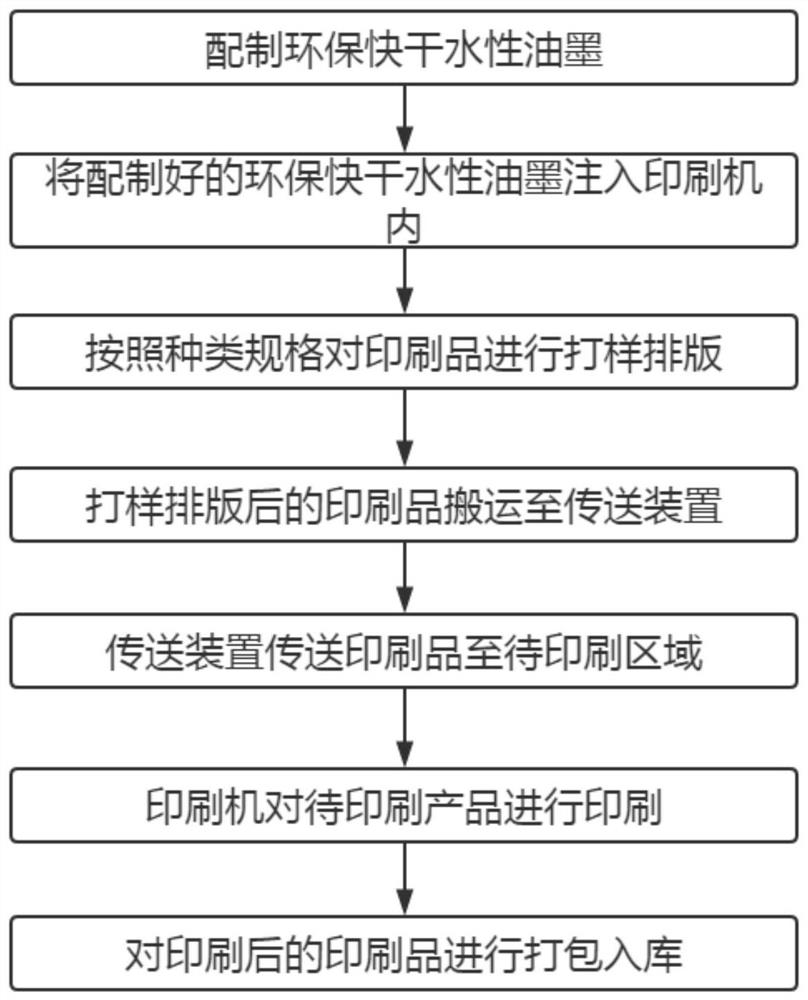

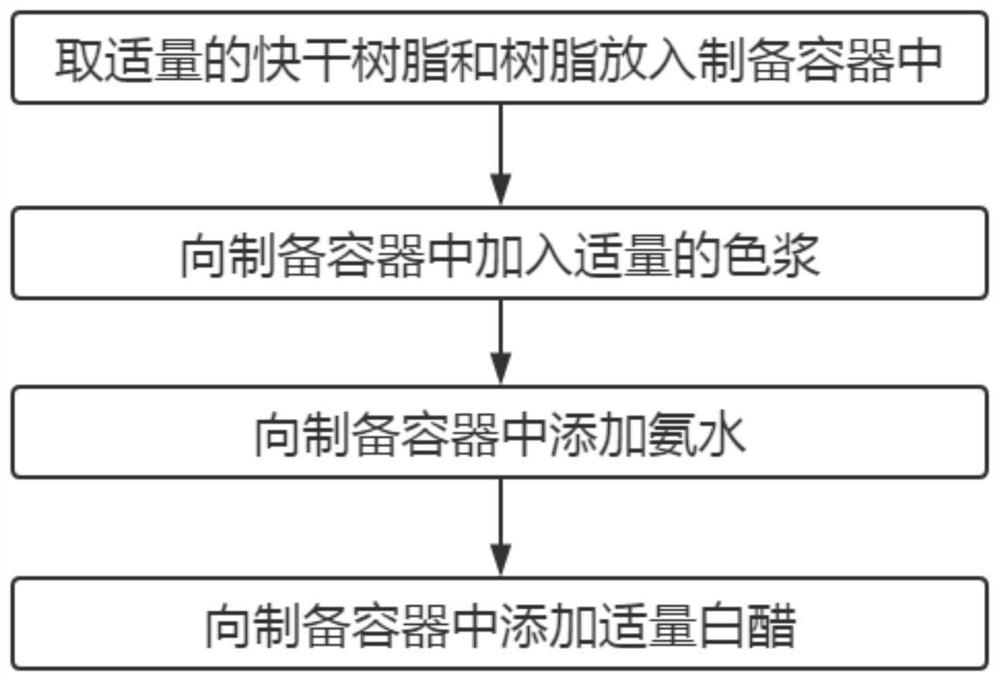

[0027] An environmentally friendly quick-drying water-based ink printing process provided by the present invention mainly includes pre-printing processing procedures, printing procedures, and post-printin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap