A kind of bamboo charcoal fiber production equipment with high drying efficiency

A technology of bamboo charcoal fiber and production equipment, which is applied in fiber processing, fiber mechanical separation, textiles and papermaking, etc., and can solve the problems of inability to clean up residues and inability to peel off carbon residue mixtures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

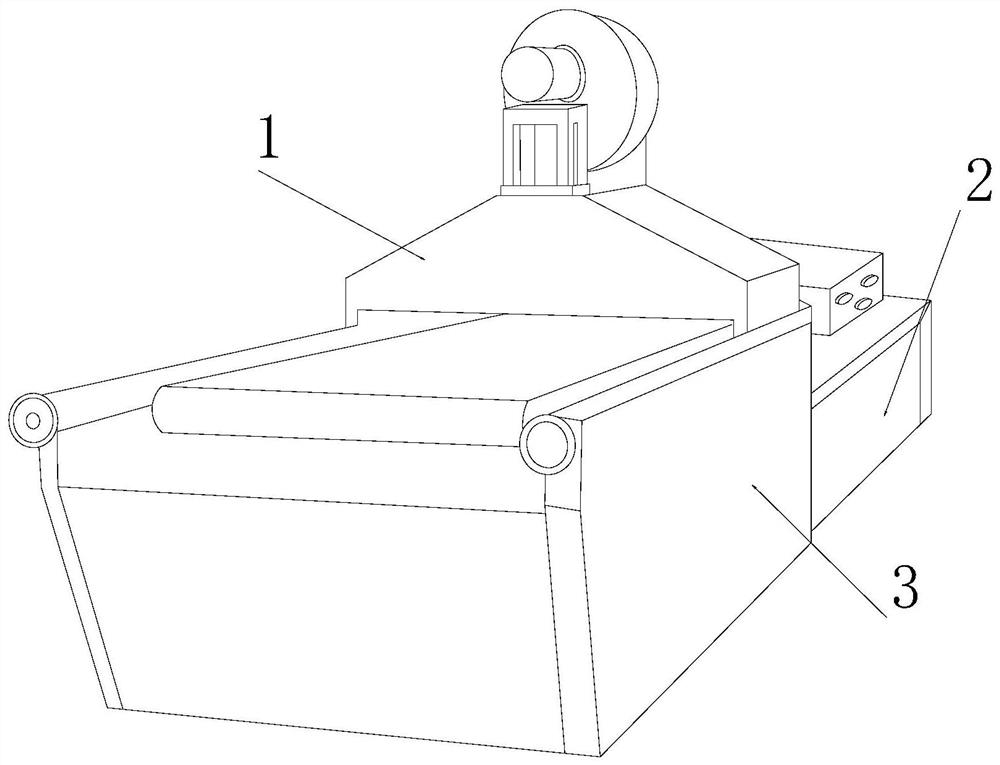

[0027] as attached figure 1 to attach Figure 6 Shown:

[0028] The present invention provides a kind of bamboo charcoal fiber production equipment with high drying efficiency, its structure comprises extruding equipment 1, picking cabin 2, equipment seat 3, described extruding equipment 1 is embedded and installed on the upper end face of equipment seat 3, described The picking cabin 2 is located under the right side of the extrusion equipment 1, and fits with the equipment seat 3, and the equipment seat 3 is located at the left end of the picking cabin 2; the extrusion equipment 1 includes an extrusion cabin 11, a blower 12 , a conveyor belt 13, a rotating shaft 14, the extrusion chamber 11 is embedded and installed directly below the blower 12, the blower 12 is located above the right side of the conveyor belt 13, and the conveyor belt 13 is attached and wrapped on the outer end surface of the rotating shaft 14, so The rotating shaft 14 is located on the left side of the ...

Embodiment 2

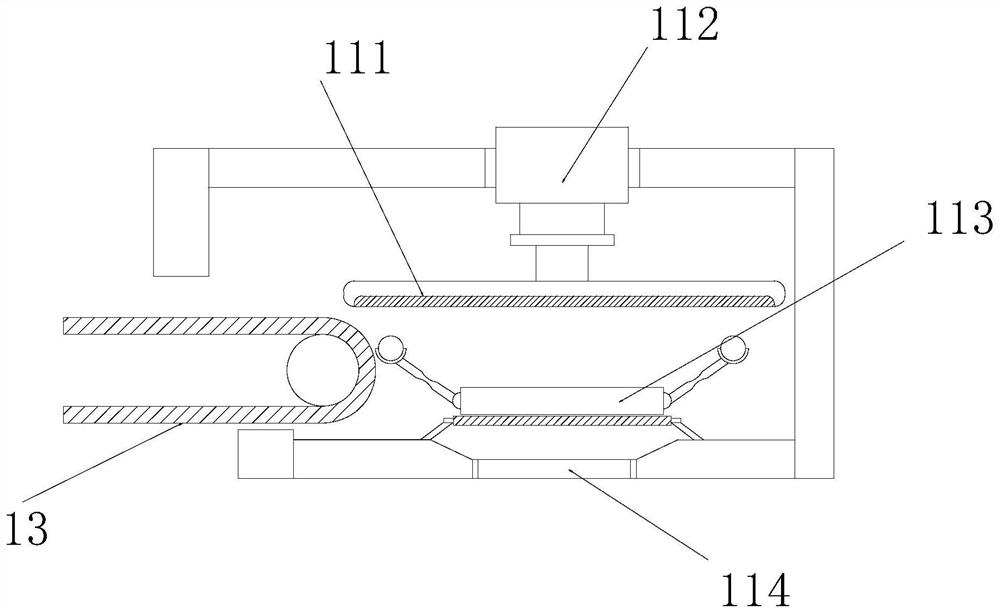

[0036] as attached Figure 4to attach Figure 8 As shown: the squeeze cabin 11 includes a squeeze plate 111, a hydraulic rod 112, a placement platform 113, and a discharge port 114. Keep parallel, the hydraulic rod 112 is located directly above the placement platform 113, the lower end surface of the placement platform 113 is embedded and installed on the inner end surface of the extrusion chamber 11, the discharge port 114 is located directly below the placement platform 113, the The upper end surface of the discharge port 114 is in the shape of an inclined disc, which can prevent the accumulation of carbon slag under the placement platform 113 .

[0037] Wherein, the screening mechanism 131 includes a placing plate 311, a second rotating shaft 312, a support roller 313, and an elastic bar 314. The end face is embedded and connected with the elastic strip 314, and the support rollers 313 are symmetrically installed on the left and right sides of the placement plate 311. Ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com