Light cement-based composite batten and manufacturing method thereof

A composite strip, cement-based technology, used in manufacturing tools, ceramic molding machines, covering/lining, etc., can solve problems such as increasing building insulation energy consumption, mold, and condensation on interior walls of houses, reducing field welding work, Avoid the effect of hot and cold bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

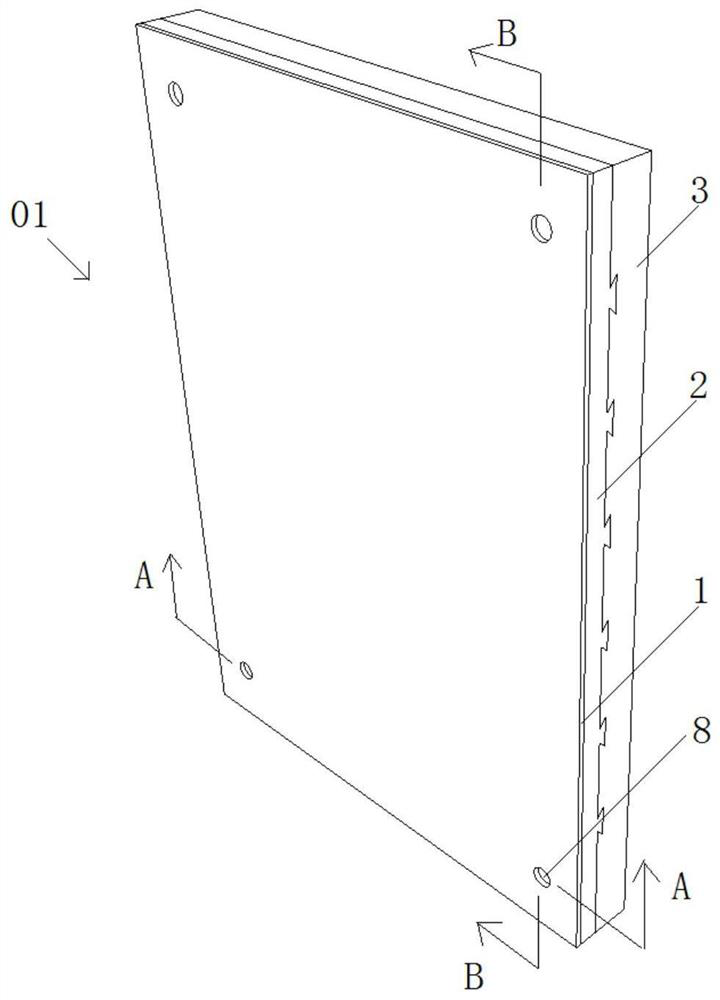

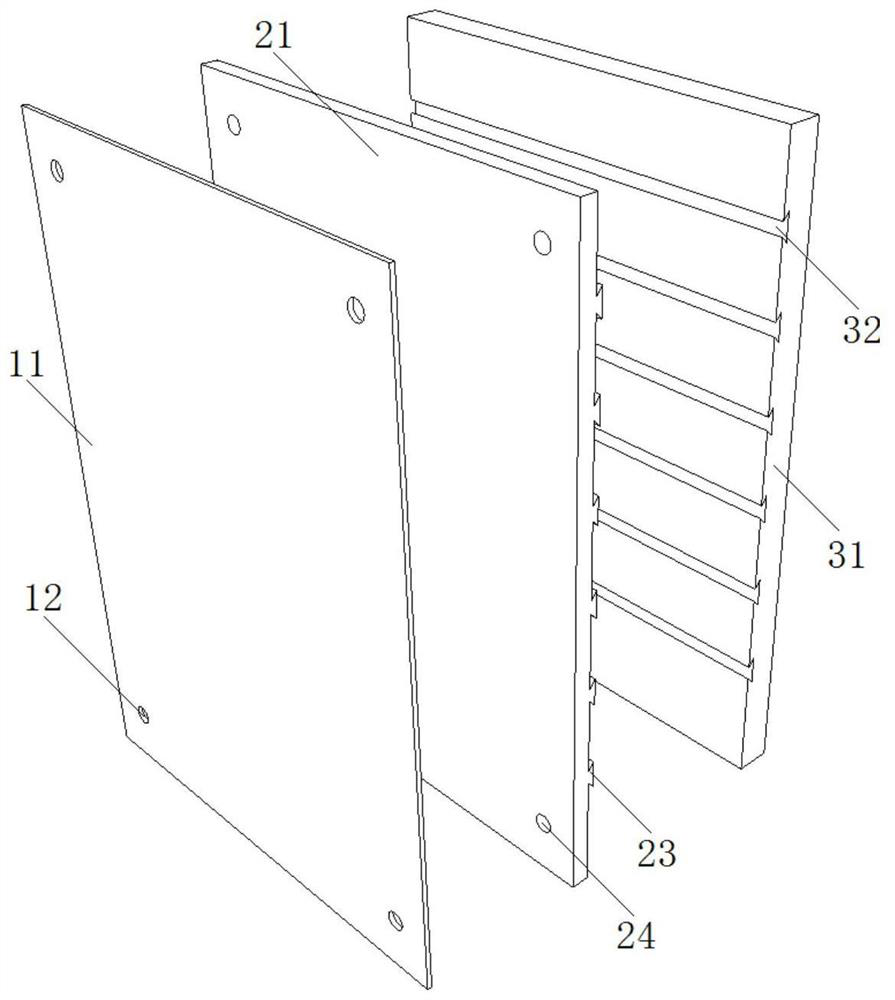

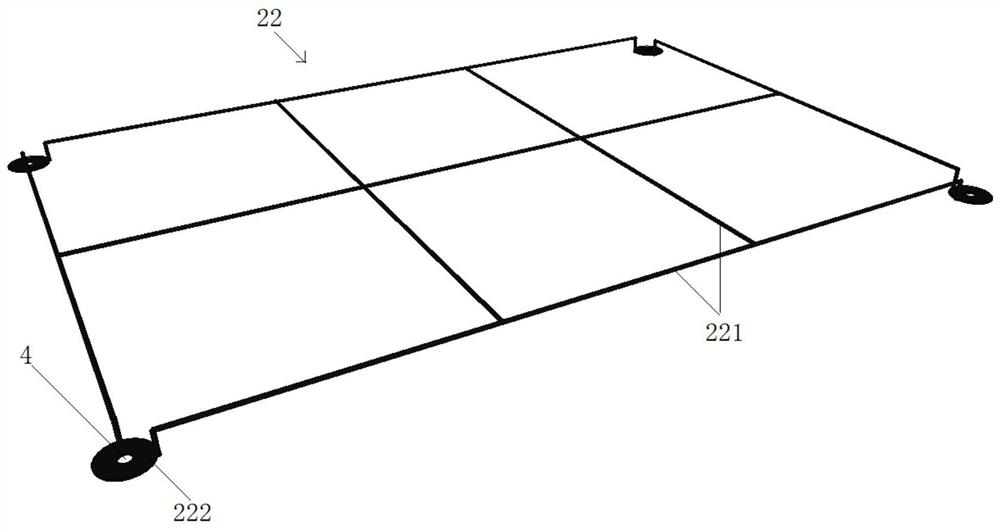

[0039] The lightweight cement-based composite strip 01 of the present invention is mainly used as a decorative wall panel for structural walls in prefabricated buildings. For the structure of the first embodiment, see Figure 1 to Figure 5 . The lightweight cement-based composite slab 01 includes a decorative surface layer 1, a concrete layer 2, and an insulation layer 3 arranged sequentially from the outside to the inside, and the decorative surface layer 1 and the concrete layer 2, as well as the concrete layer 2 and the insulation layer 3, are bonded. Connection, that is, the decorative surface layer 1 and the insulation layer 3 are consolidated into one body through the concrete layer 2, wherein:

[0040] The outermost layer of the lightweight cement-based composite strip 01 is a decorative surface layer 1, which mainly plays a decorative role, and the outer surface of the decorative plate 11 is provided with patterns, such as figure 2 As shown, the shape of the decorati...

Embodiment 2

[0049] Such as Figure 7 In the shown embodiment two, the structure of the lightweight cement-based composite slat 01 is basically the same as that of the first embodiment, and the similarities will not be repeated; the difference is that the lightweight cement-based composite slat 01 also includes the same The plug-in block 7 matched with the hole 8, the plug-in block 7 is provided with a decorative part 71 and a thermal insulation part 72, wherein the material of the decorative part 71 is the same as that of the decorative panel 11, and the thermal insulation part 72 is made of thermal insulation material, which is compatible with the decorative Part 71 is firmly bonded with construction glue. Preferably, the material of the thermal insulation portion 72 of the insert block 7 can be the same as that of the thermal insulation board 31, or it can be different, and the thickness of the thermal insulation portion 72 is based on the space in the installation hole 4 reserved when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com