Gasket material suitable for laser printing

A technology of laser printing and spacers, applied in the direction of film/sheet without carrier, pressure-sensitive film/sheet, film/sheet-shaped adhesive, etc., which can solve poor contrast, poor laser energy absorption, poor elasticity and strength and other problems, to achieve the effect of preventing the decline of tensile strength, high pressure-sensitive adhesive strength, and enhancing contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

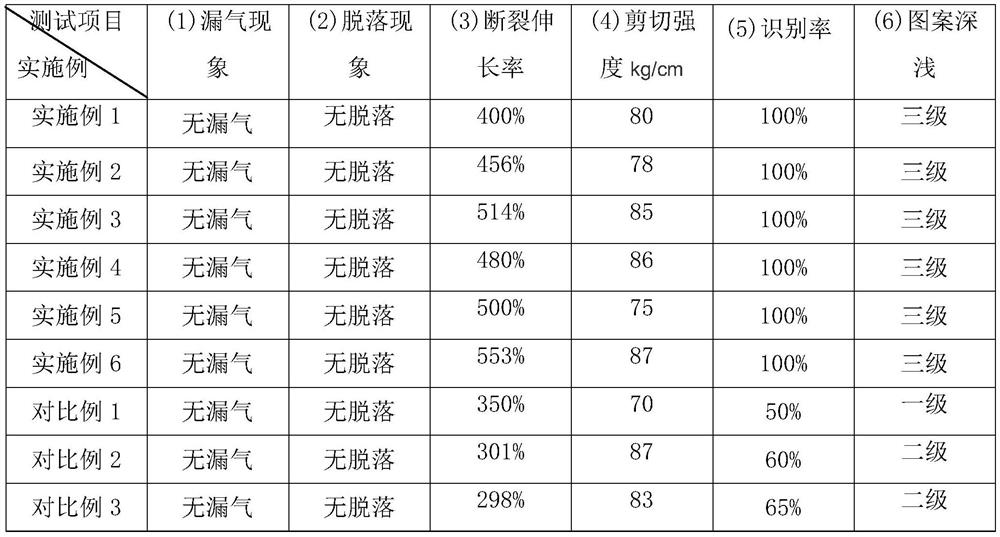

Examples

Embodiment 1

[0021] The gasket material suitable for laser printing in this embodiment is prepared from raw materials with the following weight fractions:

[0022] 50 parts of styrene-butadiene-styrene block copolymer (SBS), 40 parts of polyethylene, 15 parts of rosin soap, 10 parts of stearic acid amide, 10 parts of laser powder, 10 parts of silicon-titanium compound, Among them, the silicon-titanium composite is composed of nano silicon dioxide, nano titanium dioxide and EPDM rubber in a mass ratio of 1:1:7, and before mixing with other components, the silicon dioxide, nano titanium dioxide It is preferentially mixed with rubber to form a sol.

[0023] Among them, the number average molecular weight of styrene-butadiene-styrene block copolymer (SBS) is 5.25.2×10 5 , the mass content of polystyrene and polybutadiene blocks is 15% and 45% respectively;

[0024] Described polyethylene is linear low-density polyethylene (LLDPE) and low-density polyethylene (LDPE) and mixture, and wherein L...

Embodiment 2

[0028] 60 parts of styrene-butadiene-styrene block copolymer (SBS), 25 parts of polyethylene, 10 parts of rosin modified phenolic resin, 8 parts of stearic acid amide, 8 parts of laser powder, silicon-titanium compound 15 parts, wherein the silicon-titanium composite is composed of nano-silica, nano-titanium dioxide and isoprene rubber in a mass ratio of 1:1:8, and before mixing with other components, the silicon dioxide , Nano-titanium dioxide is preferentially mixed with rubber to form a sol.

[0029] Among them, the number average molecular weight of styrene-butadiene-styrene block copolymer (SBS) is 3.8×10 5 , the mass content of polystyrene and polybutadiene blocks is 20% and 35% respectively;

[0030] Described polyethylene is linear low-density polyethylene (LLDPE) and low-density polyethylene (LDPE) and mixture, and wherein LLDPE content is 50%, and LDPE content is 50%, and the melting index MFI of LLDPE and LDPE is respectively 4.4 / 10min ( 230°C, 2.16kg) and 0.8 / 10m...

Embodiment 3

[0034] 80 parts of styrene-isoprene-styrene block copolymer (SIS), 15 parts of polyethylene, 5 parts of disproportionated rosin, 5 parts of stearic acid amide, 5 parts of laser powder, 10 parts of silicon-titanium compound , wherein the silicon-titanium composite is composed of nano silicon dioxide, nano titanium dioxide and isoprene rubber in a mass ratio of 1:1:9, and before mixing with other components, silicon dioxide, nano Titanium dioxide is preferentially mixed with rubber to form a sol.

[0035] Among them, the number average molecular weight of styrene-isoprene-styrene block copolymer (SIS) is 1.8×10 5 , the mass content of polystyrene and polyisoprene blocks is 15% and 45% respectively;

[0036] Described polyethylene is linear low-density polyethylene (LLDPE) and low-density polyethylene (LDPE) and mixture, and wherein LLDPE content is 40%, and LDPE content is 60%, and the melting index MFI of LLDPE and LDPE is respectively 5.2 / 10min ( 230°C, 2.16kg) and 0.8 / 10min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com