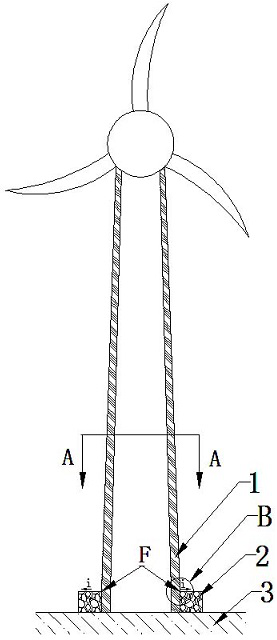

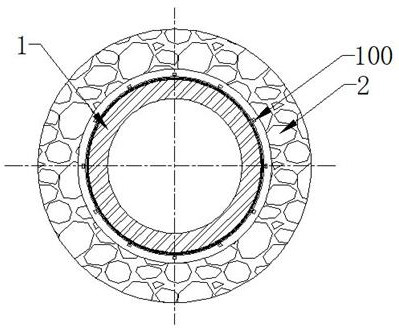

Method for improving basic waterproof performance of wind generating set

A wind turbine, basic technology, applied in wind turbines, installation/support configuration of wind turbines, wind power generation, etc., can solve problems such as water leakage in waterproof structures, and achieve the effect of ensuring waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

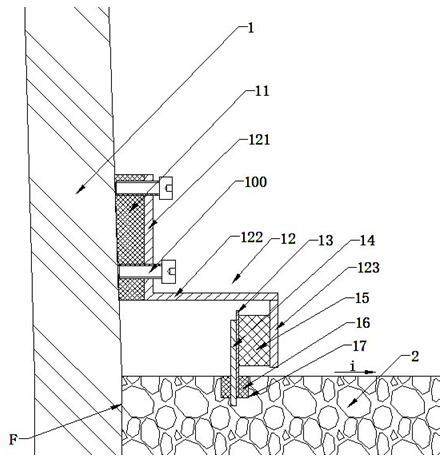

Embodiment 1

[0036] The manufacturing steps of the water guide plate 12 in the first embodiment are as follows:

[0037] Step 1. Manufacturing the water retaining plate 13:

[0038] A1. At a distance of 45 mm from the outer wall of the foundation ring 1, there is an annular groove 17 with a width of 20 mm. The depth of the annular groove 17 is determined according to the surface structure of the foundation cap 2. If there is no secondary plastering layer on the surface of the foundation cap 2, the thickness of the annular groove 17 The depth is 20 mm; if there is a secondary plastering layer on the surface of the foundation cap 2, the depth of the annular groove 17 should reach 20 mm below the surface of the primary pouring concrete. Slotting requires water drills, and it is strictly forbidden to use electric hammers to drill holes to avoid damaging the nearby concrete.

[0039] A2. In the prepared annular groove 17, drill a hole with a diameter of 20 millimeters every 50 centimeters with...

Embodiment 2

[0060] The construction steps of embodiment two are as follows:

[0061] C1. The width of the upper surface of the foundation cap 2 is 75 mm, and the depth is 20 mm. The depth of the annular groove 29 is determined according to the surface structure of the foundation cap 2. If there is no secondary plastering layer on the surface of the foundation cap 2 , The depth of the annular groove 29 is 20 millimeters. If there is a secondary plastering layer on the surface of the foundation cap 2, the depth of the annular groove 29 reaches 20 mm below the surface of the primary pouring concrete. The bottom of annular groove 29 will be smooth, avoids destroying nearby concrete when slotting.

[0062] C2, according to the position of the hole on the horizontal side 242 of the L-shaped rubber plate 24, drill a hole with a diameter of 12 millimeters in the annular groove 29, and install the stainless steel expansion screw 25 in the hole.

[0063]C3. Apply 3 mm thick structural adhesive ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com