Method for manufacturing a high-frequency connector and associated device

A technology of high-frequency connectors and paired connectors, which is applied in the direction of two-part connection devices, parts of connection devices, connections, etc., and can solve problems such as the limit of conventional manufacturing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

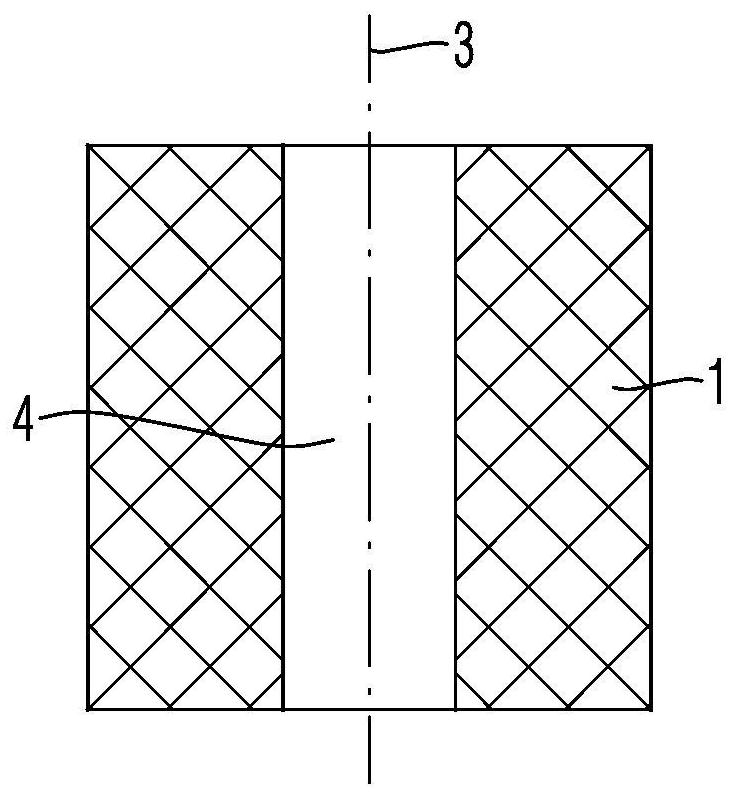

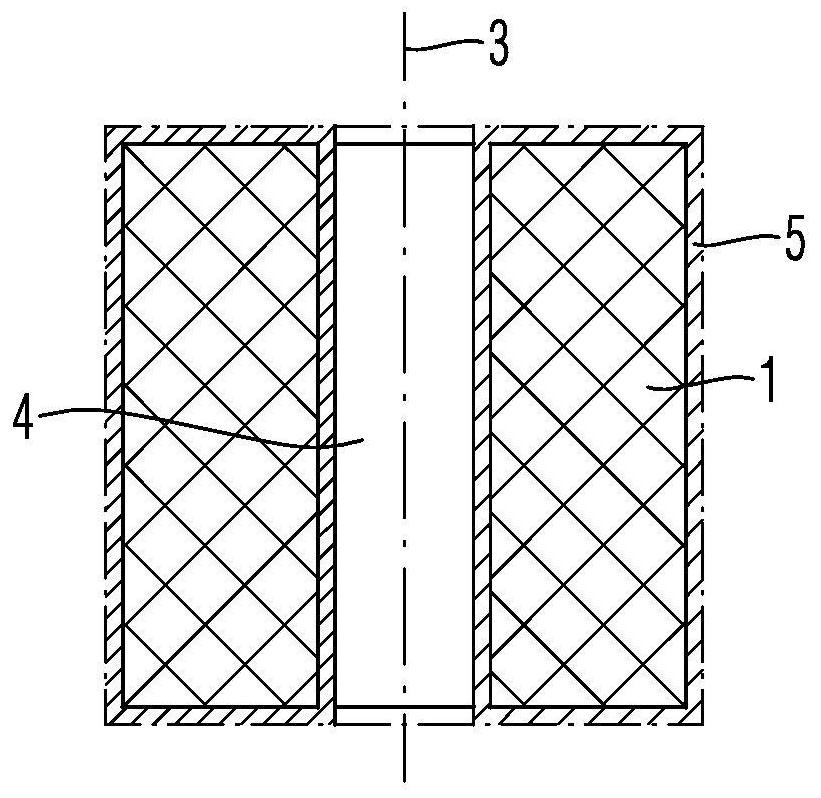

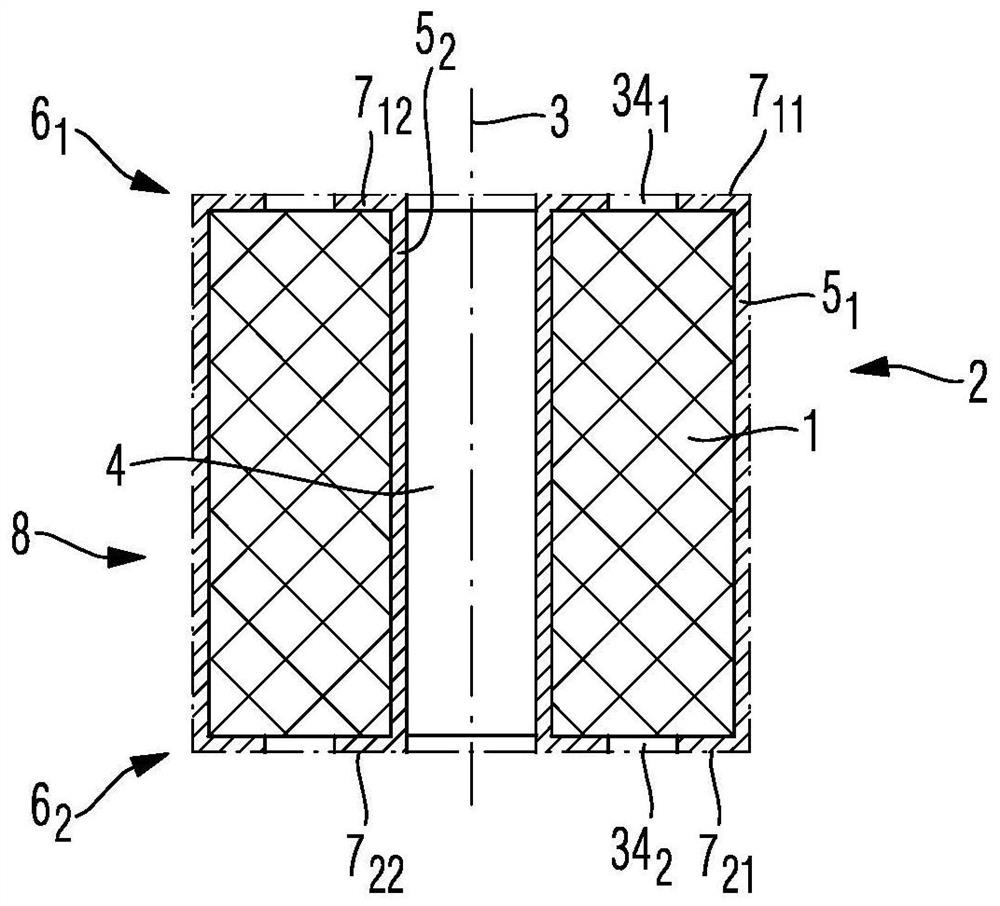

[0120] In the following, reference will be made to Figures 1A to 1C The principle of the method for producing a high-frequency connector according to the invention is explained:

[0121] exist Figure 1A In the first manufacturing step shown, the base part 1 of the high-frequency connector 2 according to the invention is produced from a dielectric material. The base part 1 has a single sleeve 4 extending along a longitudinal axis 3 . The geometry of the dielectric matrix part 1 need not necessarily be a hollow cylinder, for simplicity as Figures 1A to 1C shown. Other geometries than the hollow cylindrical geometry of the base part 1 are also conceivable, eg for high-frequency right-angle connectors.

[0122] Preferably, in order to achieve the concentricity between the inner conductor coating and the outer conductor coating of the high frequency connector 2 of the present invention, the geometry of the base part 1 is formed to be rotationally symmetrical with respect to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com