Method for reducing ferrophosphorus in furnace slag generated in electric furnace method yellow phosphorus production

A technology of yellow phosphorus and ferrophosphorus, which is applied in the field of reducing ferrophosphorus in the slag of yellow phosphorus produced by electric furnace method, so as to improve the yield of phosphorus and increase the economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

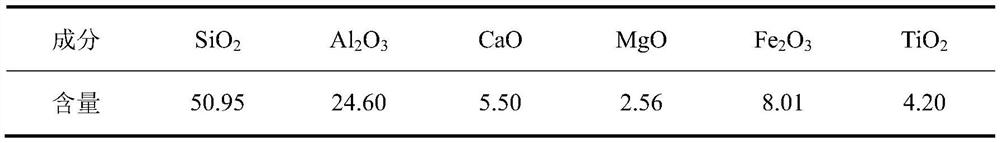

[0043] Embodiment 1: add silicon slag with 1.2 times of theoretical dosage, promptly add silicon slag 43.7g, obtain slag 781g after the experiment is finished, the content of the phosphorus iron that exists in the form of FeP is 3.1g, the conversion reaction rate of phosphorus iron is 92.2% in theory .

Embodiment 2

[0044] Embodiment 2: add silicon slag with 1.5 times of theoretical dosage, promptly add 54.8g of silicon slag, obtain slag 802g after the experiment is finished, the content of the phosphorus iron that exists with FeP form is 2.7g, the conversion reaction rate of phosphorus iron is 93.3% in theory .

Embodiment 3

[0045] Embodiment 3: add silicon slag with 2.0 times of theoretical dosage, namely add silicon slag 72.8g, after the experiment is finished, get slag 811g, the content of the phosphorus iron that exists with FeP form is 1.5g, the conversion reaction rate of phosphorus iron is 96.3% in theory .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com