A kind of crimping equipment for electric power engineering and using method thereof

A technology of crimping equipment and power engineering, applied in the direction of connection, circuit, electrical components, etc., can solve the problems of reducing the tightness of the fit, uneven seams, inconvenient operation, etc., to ensure the formation of the wire nose, improve the A tight fit that prevents the seam from catching and opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

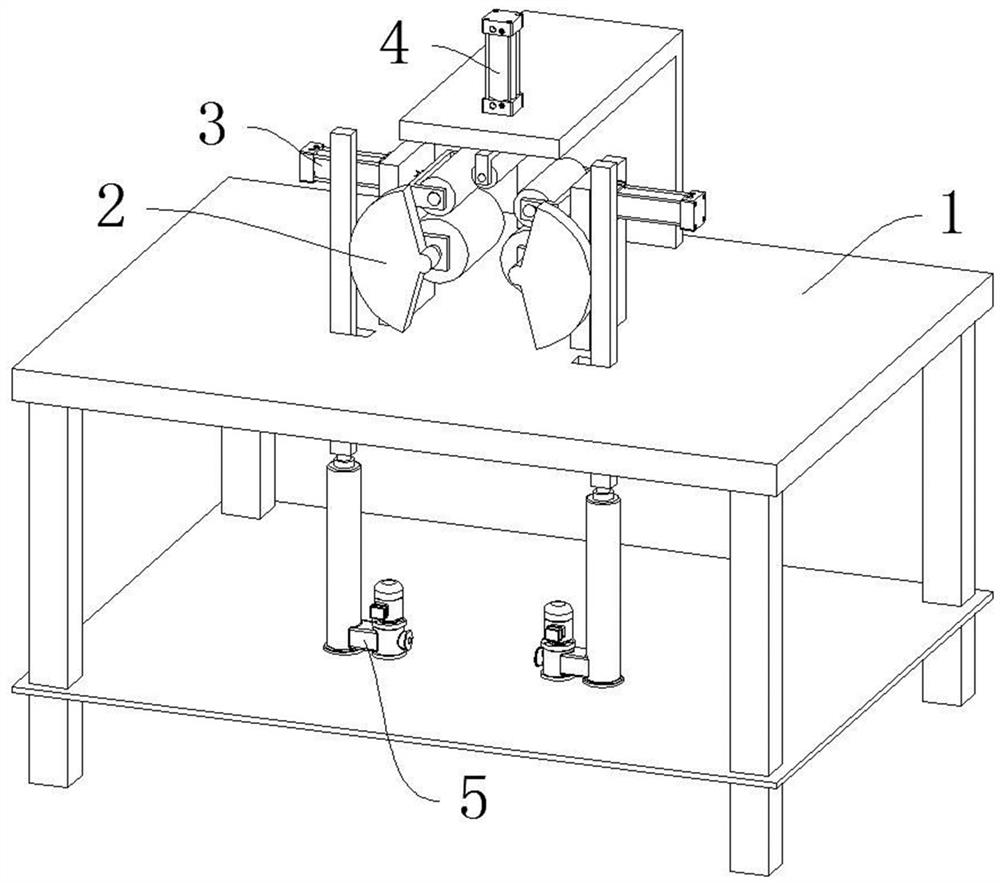

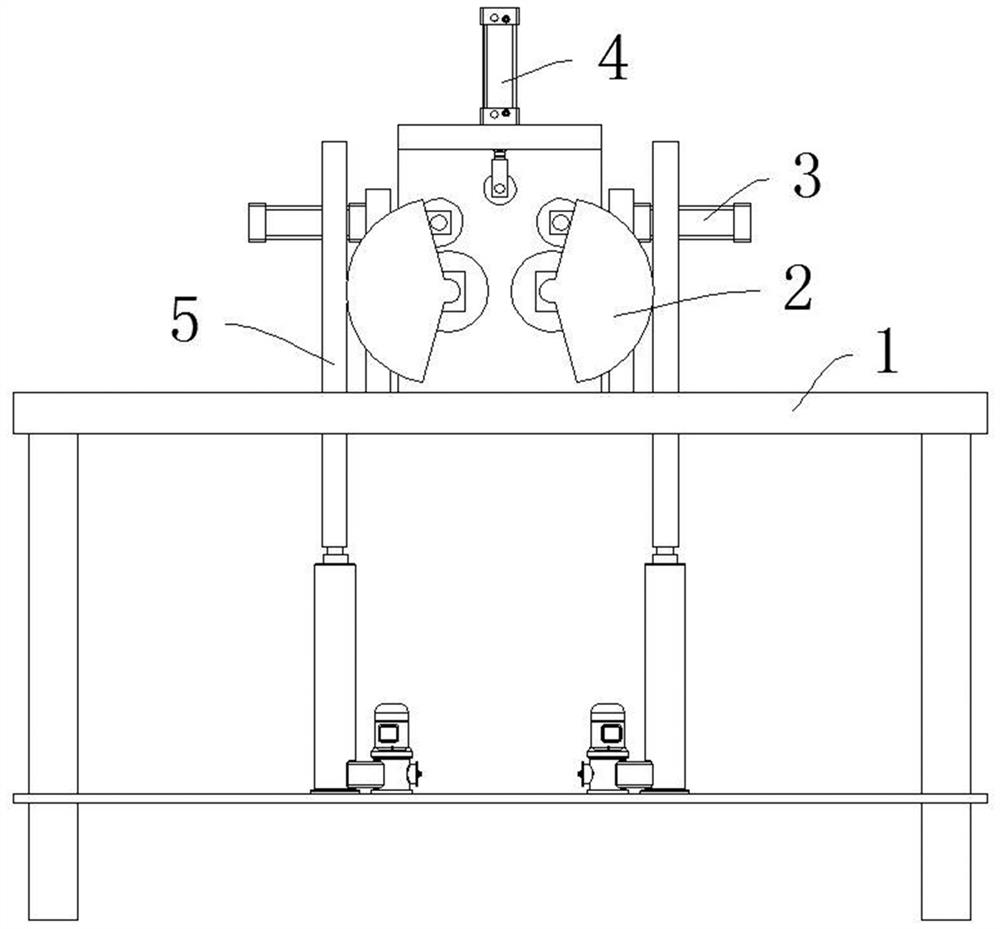

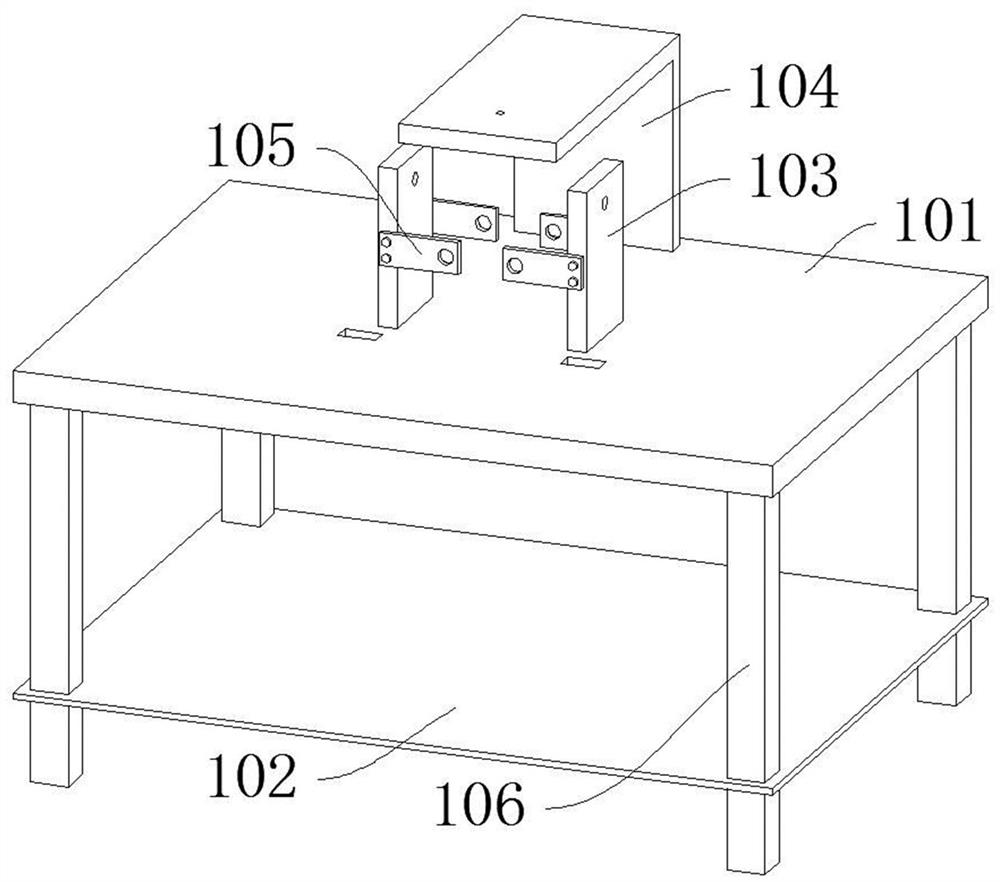

[0047] like Figure 1-Figure 7As shown, a crimping equipment used in electric power engineering includes a rack device 1 for supporting, and an overturning device 2 for overturning the wire lug, and a side press for both sides of the overturning device 2 is arranged above the overturning device 2 Device 3, above the side pressing device 3, a pressing device 4 for pressing the top is arranged, and a driving device 5 for providing power is installed symmetrically on the outside of the overturning device 2; the frame device 1 includes a support platform 101, and the four corners of the bottom of the support platform 101 are arranged There are support legs 106, a reinforcing plate 102 is arranged between the support legs 106, two support plates 103 are arranged symmetrically on the support platform 101, a support seat 105 is installed symmetrically on the front and back of the support plate 103, and a fixed frame 104 is arranged behind the support plate 103; Turning device 2 inclu...

Embodiment 2

[0050] like Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the driving device 5 includes two stepper motors 503 arranged symmetrically, and a circular gear 504 is installed behind the stepper motors 503, and the stepper motors 503 and the support table 101 are bolted together. The stepping motor 503 is connected with the circular gear 504 by a flat key, and the circular gear 504 and the half gear 204 are engaged in gear transmission.

[0051] The present invention also provides a method for using crimping equipment for power engineering, including the following steps:

[0052] a. First place the wire nose between the turning rollers 201, then pass the cable through the wire nose, the first cylinder 301 pushes the side pressure roller 303 from both sides through the first bracket 302 to press the wire nose vertical plate inward and bend;

[0053] b. Then the electric push rod 501 pushes the rack 502 to move up and down, the rack 502 meshes wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com