An assembled steel pipe concrete pile

A steel pipe concrete pile, assembled technology, applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve problems such as adjustment or removal trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

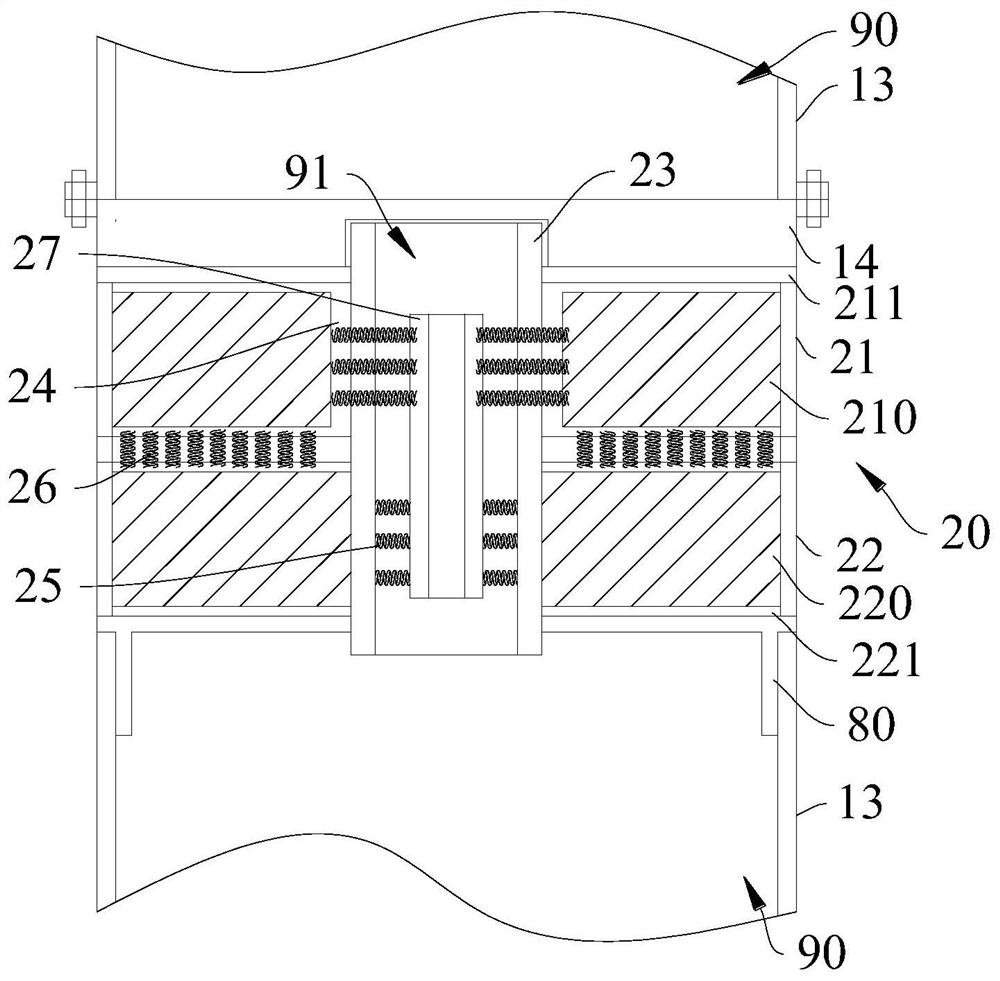

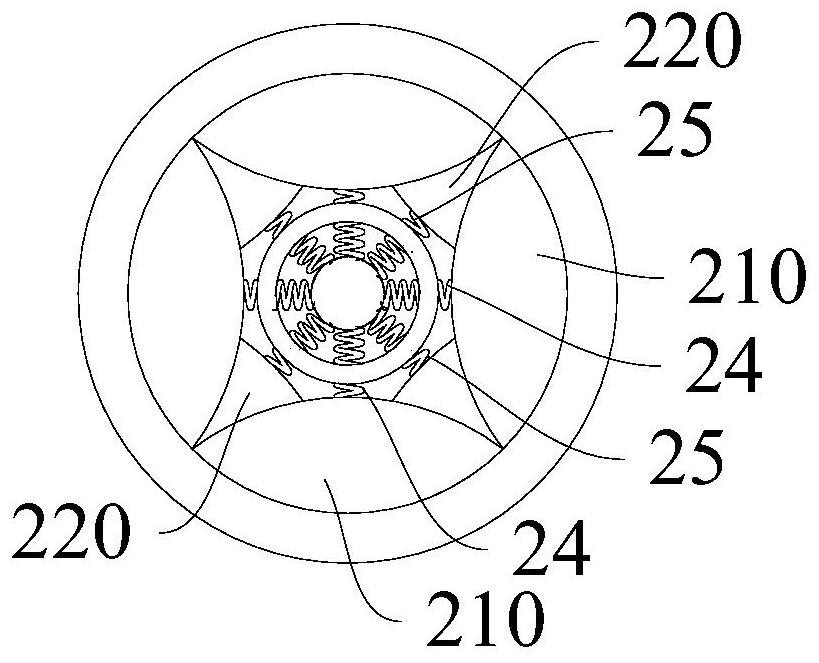

[0047] This embodiment provides an assembled concrete-filled steel pipe pile 10 , which includes a loading plate 11 , a drill bit 12 , a plurality of steel pipe units 13 and a plurality of elastic series drive units 20 .

[0048] See figure 1 , figure 1 It is a structural schematic diagram of the assembled concrete filled steel pipe pile 10 in this embodiment.

[0049] The number of steel pipe units 13 is the same as the number of elastic series drive units 20 , and in this embodiment, the number of steel pipe units 13 and the number of elastic series drive units 20 are three.

[0050] Three steel pipe units 13 are arranged sequentially along the piling direction, and two adjacent steel pipe units 13 are detachably connected by an elastic series driving unit 20, and the steel pipe unit 13 at the end can be connected to the drill bit 12 through the elastic series driving unit 20. Detachably connected, the steel pipe unit 13 at the head end is assembled with the loading plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com