Method for determining metoprolol tartrate and tablet impurities by ultra-high performance liquid chromatography

A technology of metoprolol tartrate and ultra-high performance liquid phase, which is applied in the field of analytical chemistry and can solve problems such as inability to separate and detect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

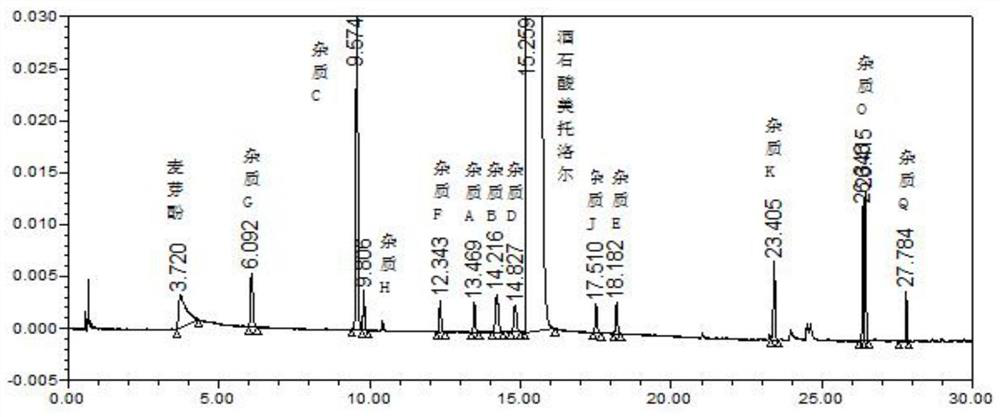

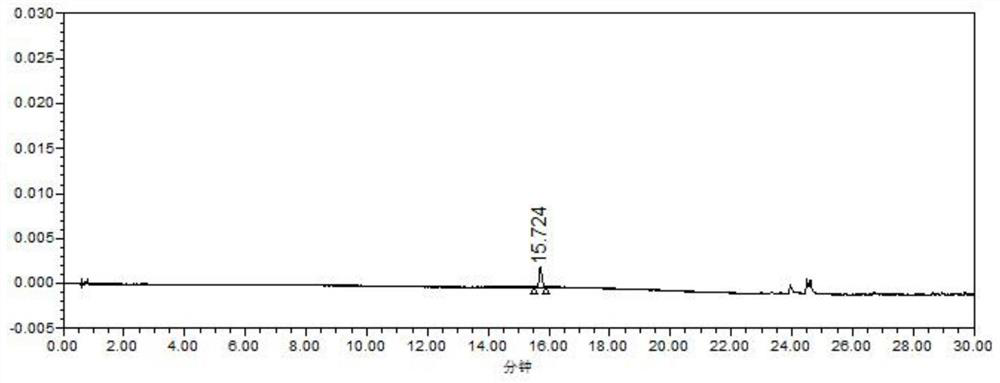

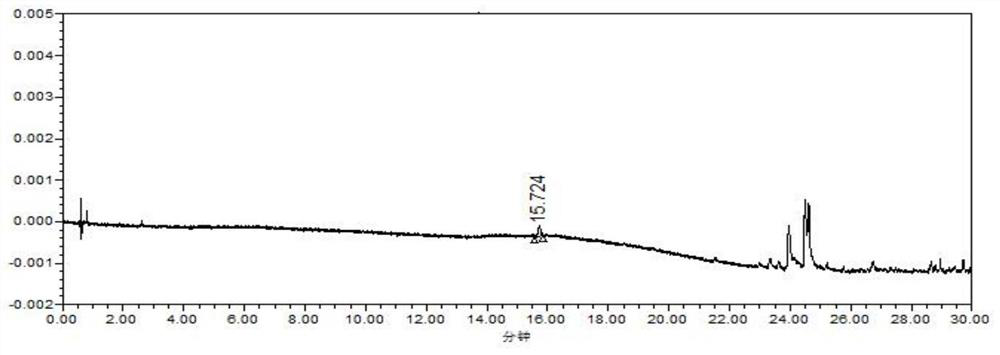

Image

Examples

Embodiment 1

[0037] The instrument and chromatographic conditions adopted are as follows:

[0038] (1) Ultra-high performance liquid chromatography: Waters UPLC H-class

[0039] Detector: PDA

[0040] Chromatographic Workstation: Empower

[0041] (2) Chromatographic column: WatersACQUITY BEH C18 column (1.7μm, 2.1mm×100mm)

[0042] (3) Mobile phase A: 0.02 mol / L sodium dihydrogen phosphate, 2% glacial acetic acid mixed buffer solution (pH=5.5) and acetonitrile in a volume ratio of 97:3. Mobile phase B phase: 0.02mol / L sodium dihydrogen phosphate, 2% glacial acetic acid mixed buffer solution (pH=5.5) and acetonitrile in a volume ratio of 30:70.

[0043] (4) Detection conditions

[0044] The mobile phases A and B are eluted according to the following gradient ratios;

[0045] Mobile phase flow rate: 0.4ml / min;

[0046] Column temperature: 35°C

[0047] Detection wavelength: 275nm

[0048] Injection volume: 2μl

[0049] Gradient table: 0 minutes to 3 minutes, mobile phase A is 100%...

Embodiment 2

[0069] The instrument and chromatographic conditions adopted are as follows:

[0070] (1) Ultra-high performance liquid chromatography: Waters UPLC H-class

[0071] Detector: PDA

[0072] Chromatography Workstation: Empower

[0073] (2) Chromatographic column: Waters ACQUITY BEH C18 column (1.7μm, 2.1mm×100mm)

[0074] (3) Mobile phase A phase: 0.015mol / L sodium dihydrogen phosphate, 1.8% glacial acetic acid mixed buffer solution (pH=5.3) and acetonitrile in a volume ratio of 97:3. Mobile phase B phase: 0.015mol / L sodium dihydrogen phosphate, 1.8% glacial acetic acid mixed buffer solution (pH=5.3) and acetonitrile in a volume ratio of 30:70.

[0075] (4) Detection conditions

[0076] The mobile phases A and B are eluted according to the following gradient ratios;

[0077] Mobile phase flow rate: 0.38ml / min;

[0078] Column temperature: 30°C

[0079] Detection wavelength: 273nm

[0080] Injection volume: 1μl

[0081] Gradient table: 0 minutes to 3 minutes, mobile pha...

Embodiment 3

[0086] The instrument and chromatographic conditions adopted are as follows:

[0087] (1) Ultra-high performance liquid chromatography: Waters UPLC H-class

[0088] Detector: PDA

[0089] Chromatography Workstation: Empower

[0090] (2) Chromatographic column: WatersACQUITY BEH C18 column (1.7μm, 2.1mm×100mm)

[0091] (3) Mobile phase A: 0.025 mol / L sodium dihydrogen phosphate, 2.2% glacial acetic acid mixed buffer solution (pH=5.7) and acetonitrile in a volume ratio of 97:3. Mobile phase B phase: 0.025mol / L sodium dihydrogen phosphate, 2.2% glacial acetic acid mixed buffer solution (pH=5.7) and acetonitrile in a volume ratio of 30:70.

[0092] (4) Detection conditions

[0093] The mobile phases A and B are eluted according to the following gradient ratios;

[0094] Mobile phase flow rate: 0.42ml / min;

[0095] Column temperature: 40°C

[0096] Detection wavelength: 277nm

[0097] Injection volume: 5μl

[0098] Gradient table: 0 minutes to 3 minutes, mobile phase A i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com