A rotary electroplating mechanical cantilever conductive mechanism

A rotary, rotating mechanism technology, used in current conducting devices, electrolysis components, electrolysis processes, etc., can solve the problems of high temperature softening of insulating skins, damage to insulating skins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

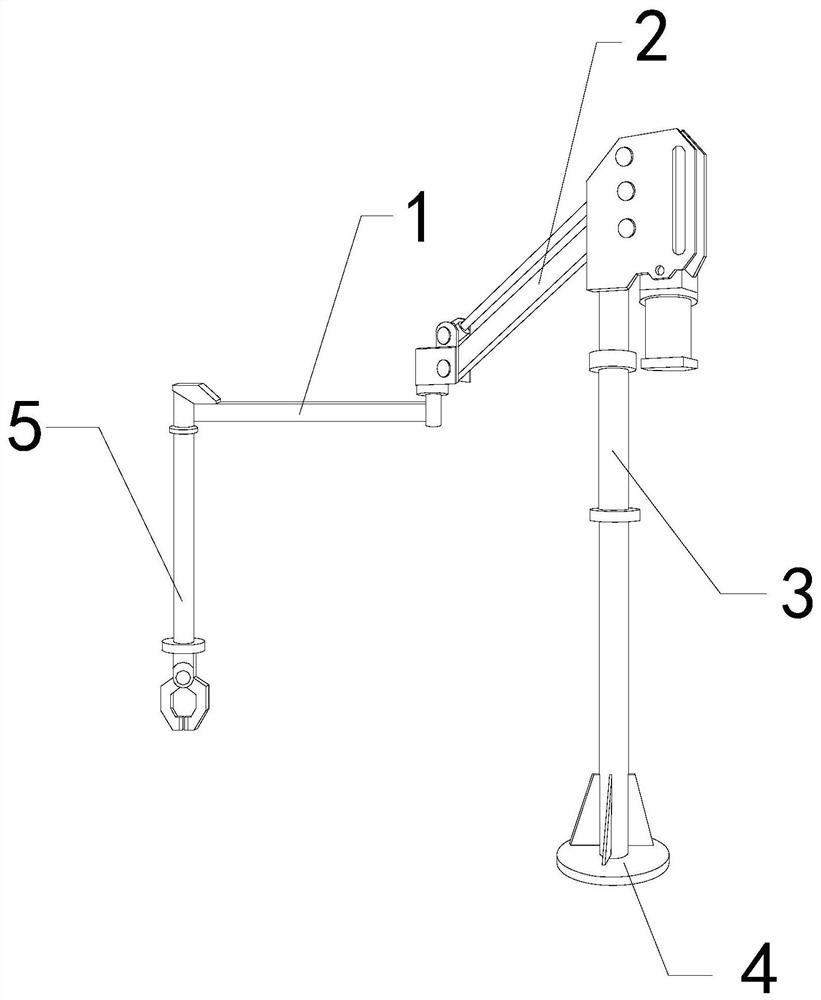

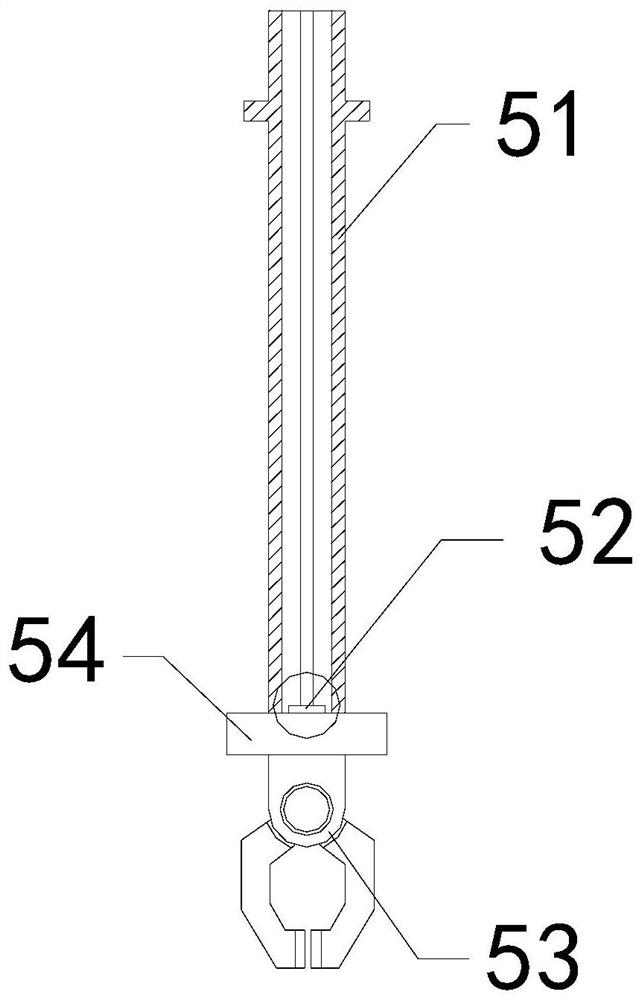

[0026] For example figure 1 -example Figure 5 Shown:

[0027] The invention provides a cantilever conductive mechanism of a rotary electroplating machine, the structure of which includes a middle connecting rod 1, an engaging arm 2, a support rod 3, a base 4, and a clamping mechanism 5, and the middle connecting rod 1 and the connecting arm 2 are movably engaged. , the connecting arm 2 is connected to the upper end of the support rod 3, the support rod 3 is welded to the base 4, the clamping mechanism 5 is installed at the front end of the connecting rod 1; the clamping mechanism 5 includes an outer Frame 51, conductive mechanism 52, clamping head 53, rotating disk 54, the outer frame 51 is connected with the rotating disk 54, the conductive mechanism 52 is embedded in the upper end position of the rotating disk 54, and the clamping head 53 is installed At the bottom position of the rotating disk 54.

[0028] Wherein, the conductive mechanism 52 includes a heat conduction ...

Embodiment 2

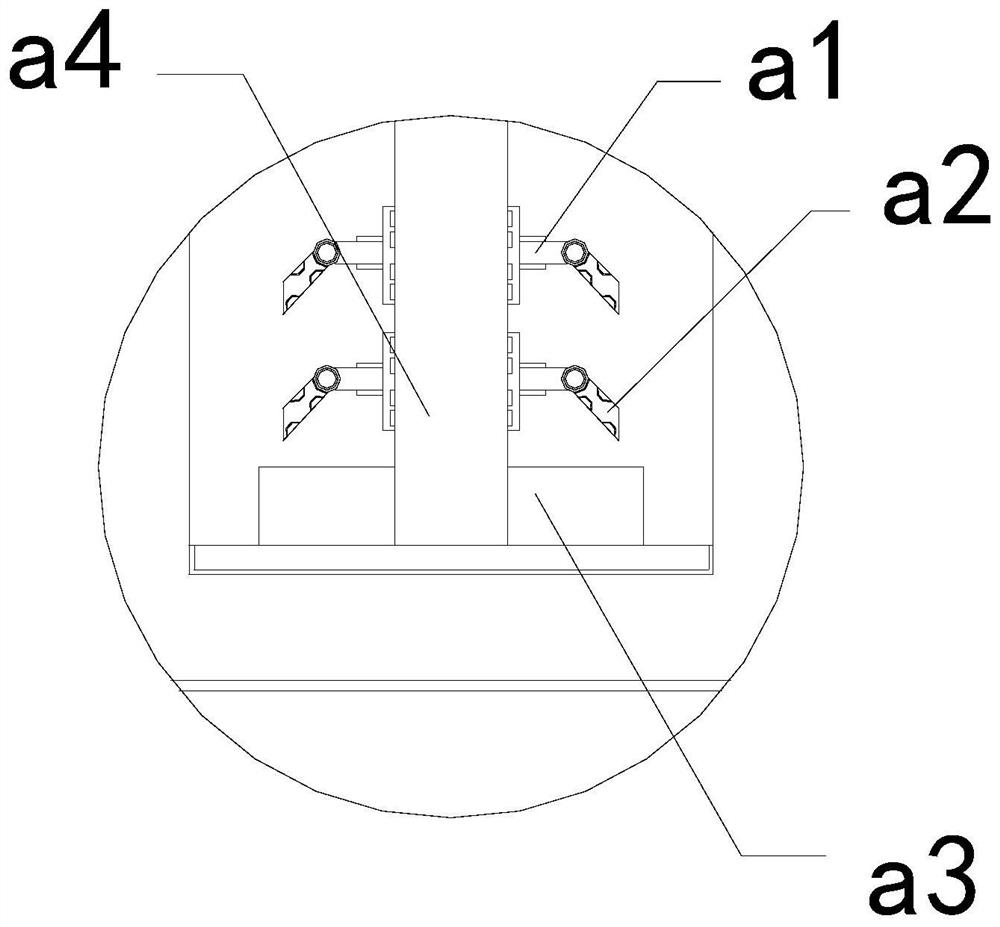

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the wire fixing ring a35 includes a fixed block c1, a booster bar c2, an overhanging frame c3, and an outer ring c4, the fixed block c1 and the outer ring c4 are an integrated structure, and the booster bar c2 is installed Between the block c1 and the outrigger c3, the outrigger c3 is movably engaged with the inner position of the fixed block c1 and the outer ring c4, and there are six outriggers c3, which are evenly placed on the outer ring c4 Distributed in a circular shape, through the thrust generated by the booster bar c2 on the outrigger c3, the outrigger c3 can fix the position of the conductive wire.

[0036] Wherein, the outstretched frame c3 includes a plate body c31, an elastic piece c32, an inner clamping block c33, a transmission line c34, and a linkage rod c35, and the elastic piece c32 is installed between the plate body c31 and the inner clamping block c33. The inner clamping block c33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com