Food waste disposer throat baffle apparatus and method

A technology for food waste treatment and partitions, applied in the field of partitions or splash-proof parts or features, can solve problems such as side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

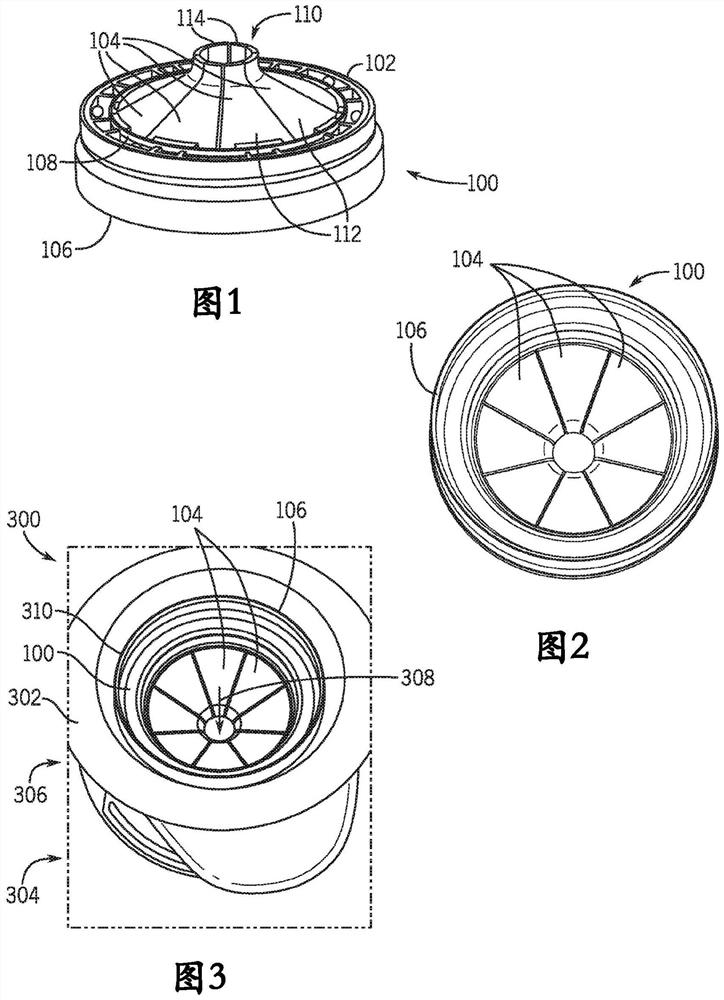

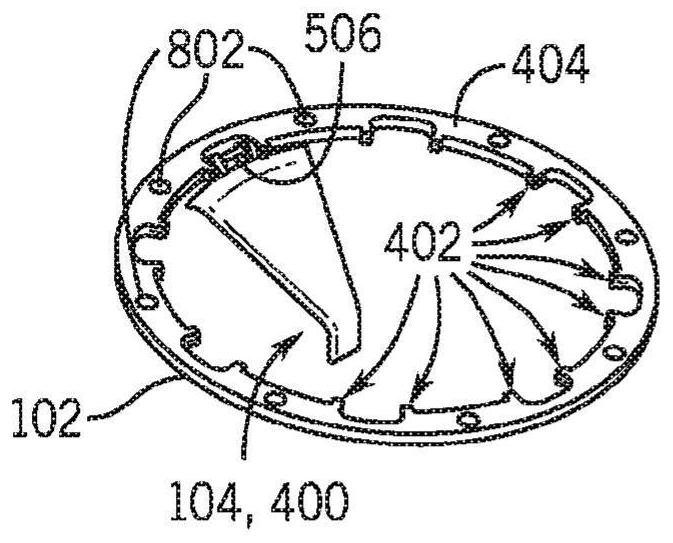

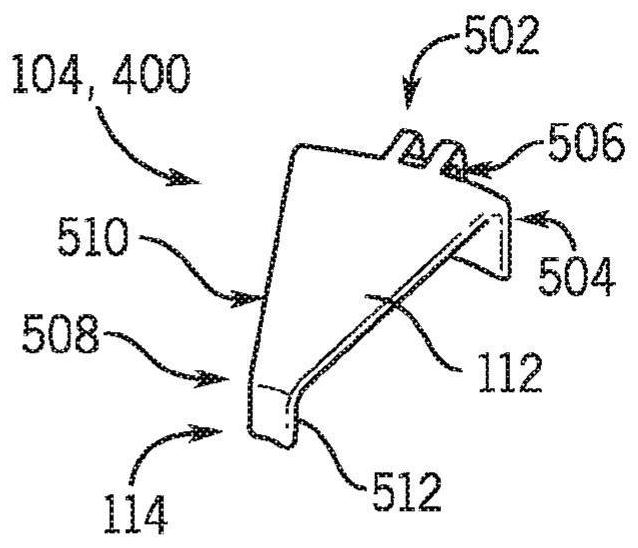

[0039] The present disclosure is intended to encompass any of various dividers, food disposer systems employing such dividers, or methods of operating, assembling, processing, manufacturing, or implementing dividers or food waste disposer systems. In at least some such embodiments, so long as the diaphragm has flaps (rather than folds) and one or more components or features that tend to maintain the flaps in the closed position or return to the closed position when not in the closed position , it can be regarded as a movable partition. In at least some such embodiments, one or more of the components or features may include a living hinge by which the flaps are linked to an external support portion of the bulkhead, such as a rim portion or a support ring structure, such that the flaps, flaps, The hinge and the outer support part are integrally formed. In at least some other embodiments, one or more components or features may include an elastic band. With this configuration, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com