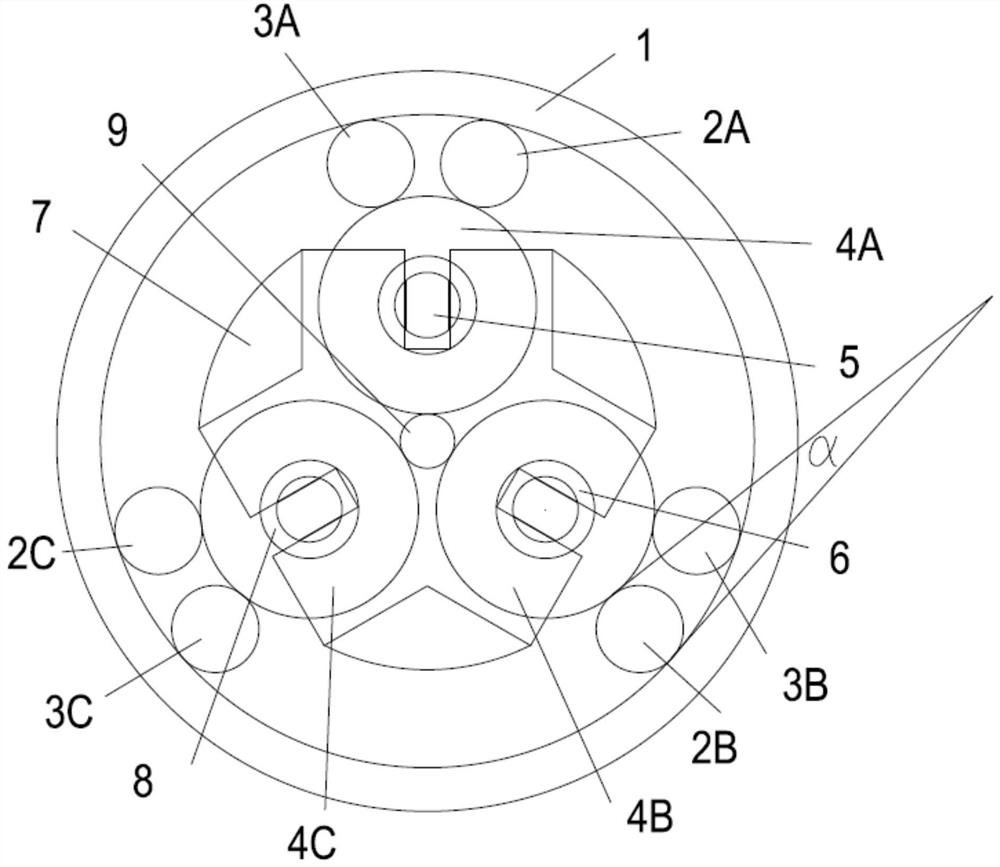

Planetary traction drive

A traction drive, planetary technology, applied in the direction of transmission, friction transmission, belt/chain/gear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

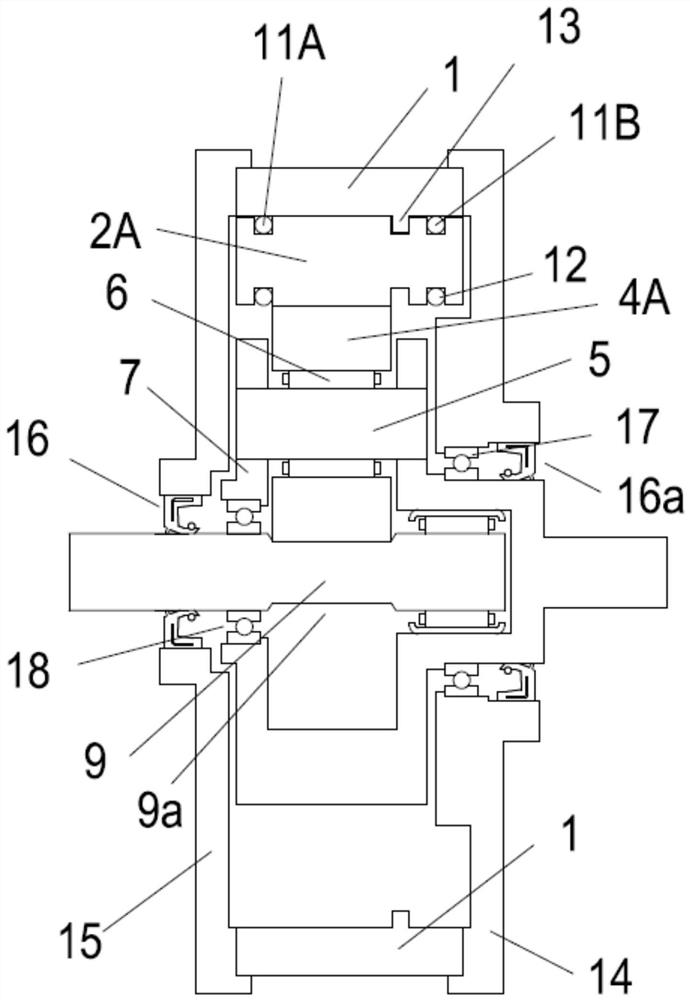

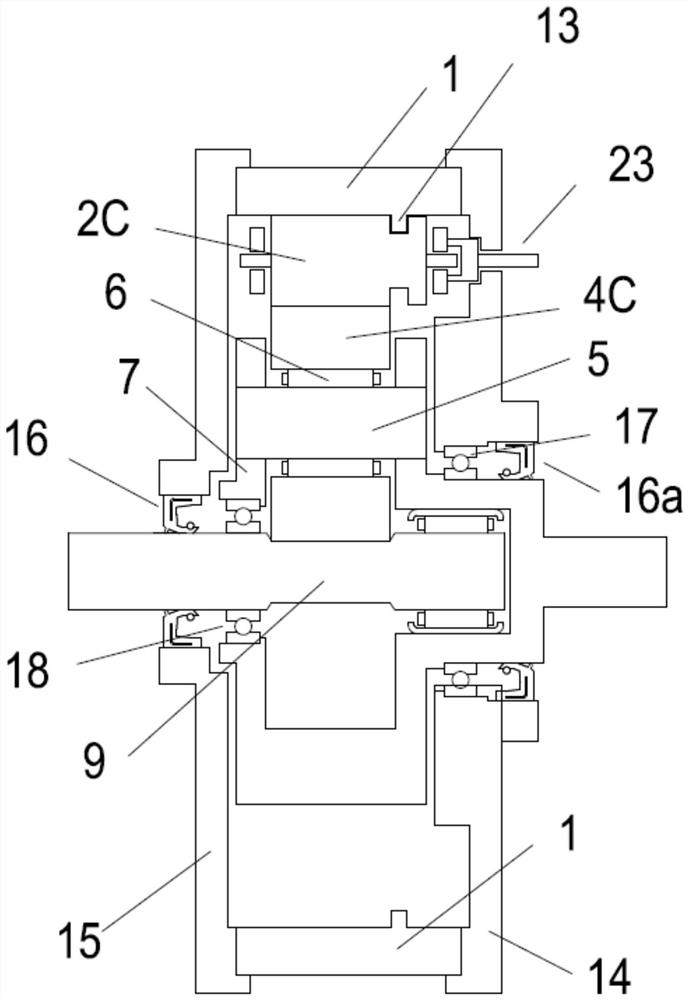

[0026] The invention will be described with reference to the accompanying examples, which are examples of embodiments of the invention, but do not limit the scope of the invention. For example, the number of planetary rollers and wedge rollers may vary, the support and bearing arrangement may vary according to the particular application, and the dimensions and materials used may vary according to the specific requirements of the particular application of the invention.

[0027] It is also important to understand that with conventional geared epicyclic systems using the sun, rings, planets, and planetary carriers, twelve rotational states are possible and are commonly used in mechanical systems.

[0028] 1) Carriage fixed, torque input to the sun and output to the carriage

[0029] 2) Carriage fixed, torque input to the ring and output to the sun

[0030] 3) Sun fixed, torque input from the ring and output from the carrier

[0031] 4) Sun fixed, torque input to carrier and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com