Reverse operation construction rapid channel sinking culvert construction method

A construction method and fast technology, applied in the direction of roads, roads, artificial islands, etc., can solve the inconvenience of pedestrians crossing the road, and achieve the effect of fast construction progress, avoiding inconvenience, and saving cantilever support piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

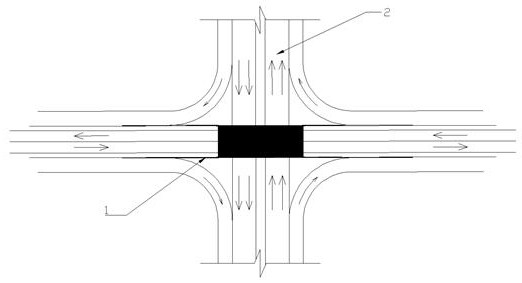

[0038] Such as Figure 1-9 Shown is a construction method for the sinking culvert of the fast track by reverse operation, the sinking culvert 1 is located under the road surface of the fast track 2, and the steps of the construction method are:

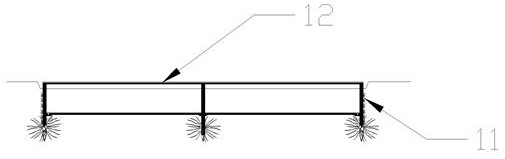

[0039] S1: Prefabricated piles and beams: The prefabricated piles 11 and prefabricated beams 12 required for forming are poured outside the construction site, and the prefabricated piles 11 have their own vacuum downwater pipes. Different specifications are prefabricated at different positions of 1. The prefabricated pile 11 is composed of a pile point and a pile body, and the pile point is fixed at the bottom of the pile body, and a vacuum downwater pipe is installed inside the pile body.

[0040] S2: Expressway road surface segmentation: divide the road surface of expressway 2 into three sections in the width direction, the first section of road surface 21 is a quarter of the width of the expressway road surface adjacent to the exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com