Graphite processing grinding device

A grinding device and graphite technology, applied in grain processing and other directions, can solve the problems of reducing the grinding efficiency of graphite and the grinding effect is not ideal, and achieve the effect of improving grinding efficiency, improving grinding effect and facilitating collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

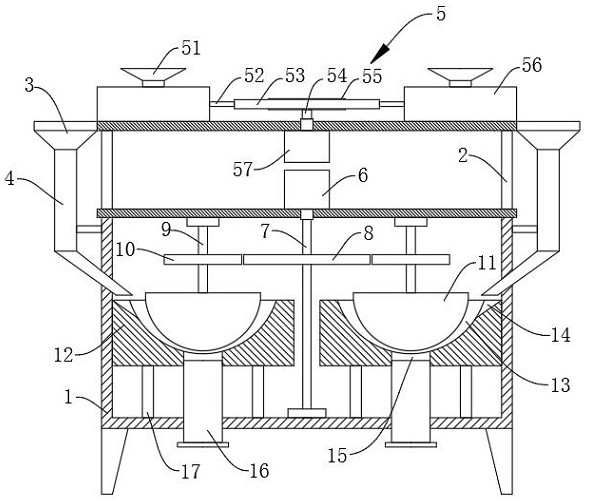

[0021] refer to Figure 1-4 , a grinding device for graphite processing, comprising a box body 1, the upper end of the box body 1 is fixedly connected with a bracket 2, the two ends of the bracket 2 are respectively fixedly connected with a funnel 3, and the lower ends of the two funnels 3 are respectively fixedly connected with a feed pipe 4, and the lower ends of the two feeding pipes 4 respectively penetrate into the inside of the box body 1, and the upper surface of the bracket 2 is provided with a feeding mechanism 5, which is used for feeding, and through the feeding mechanism 5, it can Two different raw materials are made to enter into two hoppers 3 , and then two different raw materials are made to enter into the device through two feed pipes 4 .

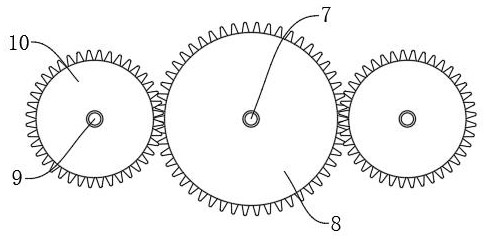

[0022] The middle part of the upper surface of the box body 1 is fixedly connected with a first motor 6, and the first motor 6 is connected with an external power supply device through a wire, and a switch for controlling th...

Embodiment 2

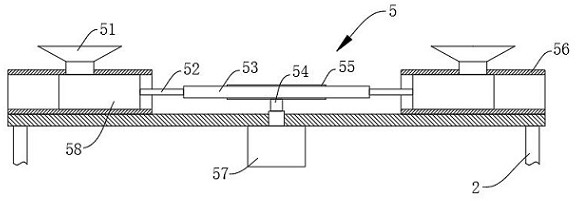

[0027] refer to figure 1 , figure 2 and Figure 4 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the feeding mechanism 5 includes two material boxes 56, and the two material boxes 56 are respectively fixedly connected to both sides of the upper surface of the support 2, and the two The upper surfaces of the hoppers 56 are respectively fixedly connected with the feeding hoppers 51, and the insides of the two hoppers 56 are respectively slidably provided with piston push blocks 58, and a reciprocating mechanism is arranged between the two piston push blocks 58, and the reciprocating mechanism It is arranged on the support 2, and through the two feeding hoppers 51, two different raw materials can be fed into the two bins 56 respectively.

Embodiment 3

[0029] refer to figure 1 , figure 2 and Figure 4 , as another preferred embodiment of the present invention, the difference from Embodiment 2 is that the reciprocating mechanism includes two push rods 52 and a second motor 57, and the two push rods 52 are respectively fixedly connected to two piston push blocks 58 opposite In the middle of one end, the second motor 57 is fixedly connected to the middle of the lower surface of the support 2. The second motor 57 is connected to the external power supply device through a wire, and the wire is fixedly connected with a switch for controlling the operation of the second motor 57.

[0030] A mounting frame 53 is fixedly connected between the two push rods 52, and a rack 59 is fixedly connected to both sides of the mounting frame 53 inner wall respectively, and is relatively arranged between the two racks 59, and one end of the output shaft of the second motor 57 can be The bracket 2 is rotatably penetrated and fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com