Auxiliary device for facilitating disassembly and assembly of drift tube and method of use thereof

An auxiliary device and drift tube technology, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems affecting the surface accuracy and installation accuracy of the drift tube, bumping the drift tube, etc., so as to reduce the labor intensity, avoid interference or damage, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

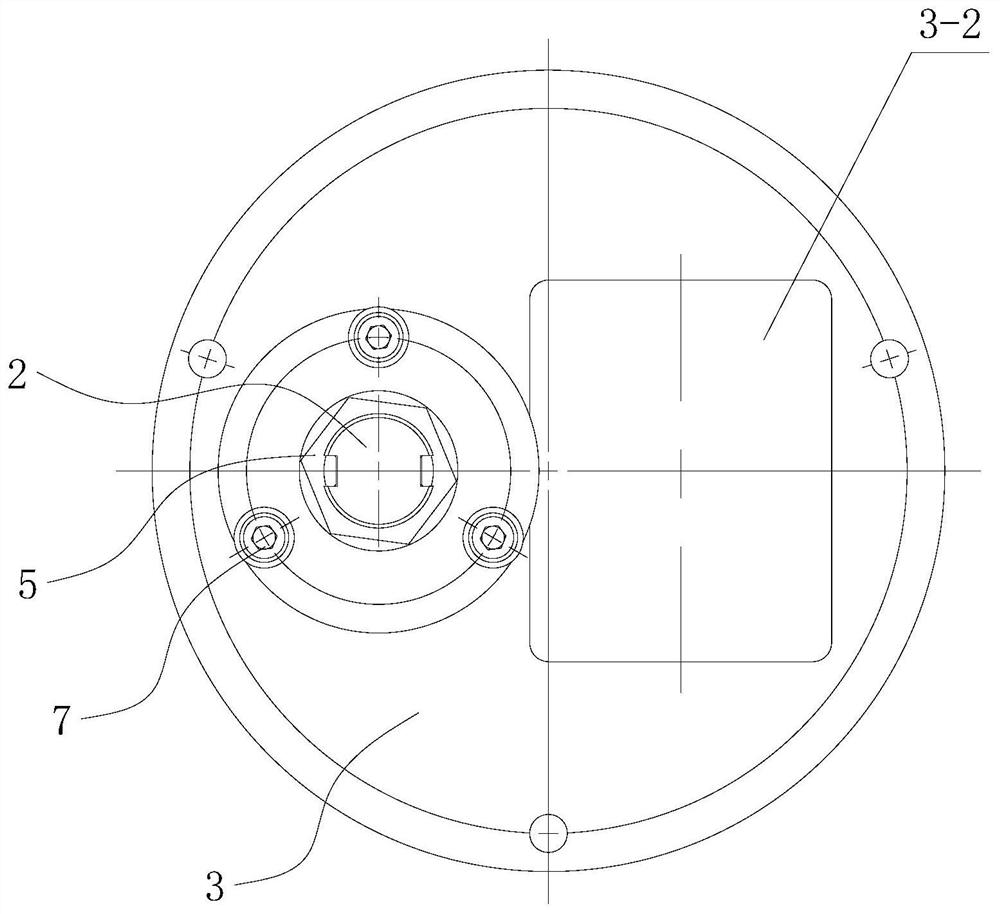

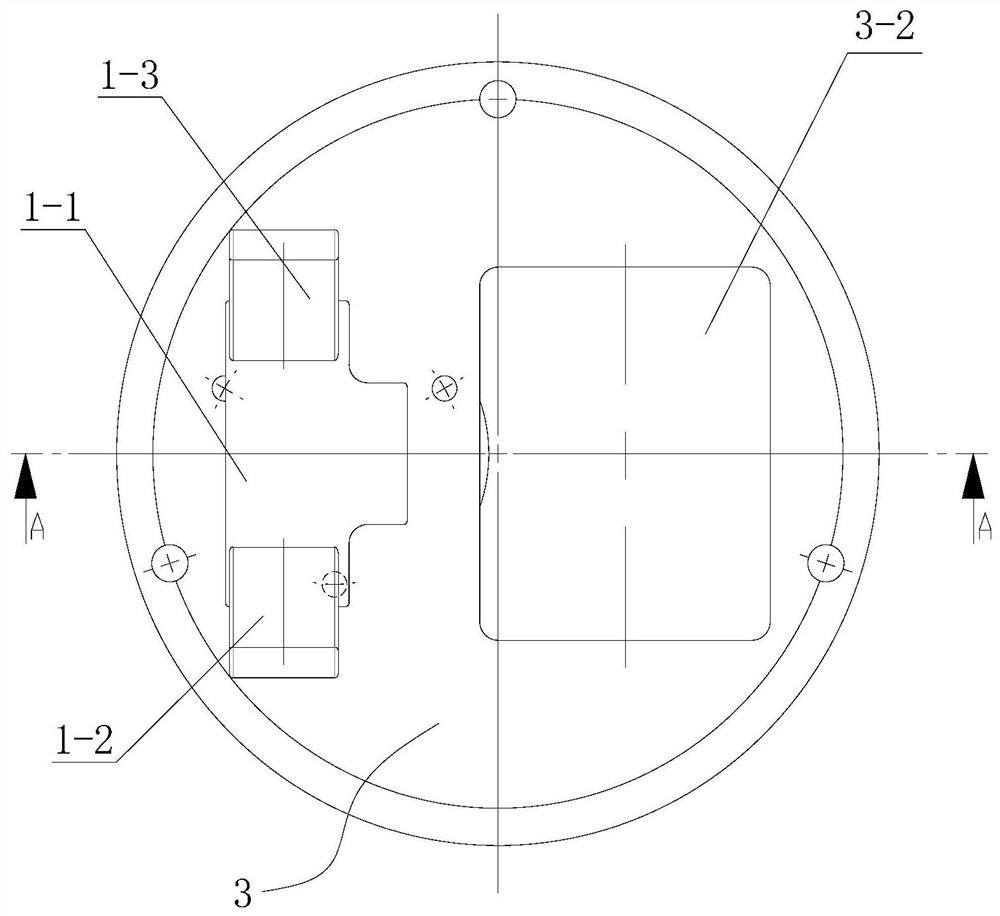

[0049] In this embodiment, an auxiliary device for facilitating the disassembly and assembly of the drift tube, such as Figure 1 to Figure 4 As shown, it includes supporting plate assembly 1, connecting screw 2, flange plate 3, pressure plate 4 and adjusting nut 5. The bottom of the supporting plate assembly is connected with the flange plate through the connecting screw rod, and the lower end of the connecting screw rod passes through the flange plate and connects with the adjusting nut Threaded connection, there is also a pressure plate at the junction of the adjusting nut and the flange; Figure 7 or Figure 8 As shown, the upper part of the support plate assembly is in contact with the bottom of the drift tube 9, and the outer periphery of the flange is installed in the through hole 8 at the bottom of the linear accelerator cavity. Among them, the supporting plate assembly is used to support the drift tube, so as to disassemble or install the drift tube; the flange plate...

Embodiment 2

[0055] This embodiment is the method of using the auxiliary device for facilitating the disassembly and assembly of the drift tube in Embodiment 1, which mainly includes the following steps:

[0056] (1) The adjusting nut is pre-embedded in the pressure plate;

[0057] (2) The upper end of the connecting screw is welded to the supporting plate assembly, and the lower end of the connecting screw passes through the flange and is connected to the adjusting nut;

[0058] (3) Rotate the adjusting nut until it connects with the bottom of the flange. At this time, the pressure plate is also in contact with the bottom of the flange. Use bolts to pass through the pressure plate and screw into the flange, but do not tighten the bolts;

[0059] (4) The flange is fixedly installed in the through hole at the bottom of the cavity of the linear accelerator by means of bolt connection;

[0060] So far, by turning the adjusting nut, the connecting screw drives the supporting plate assembly to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com