Air intake regulating mechanism and turbocharger compressor using same

A technology of air intake adjustment and compressor impeller, which is applied in the field of compressors, can solve the problems of inability to adjust the air flow rate of the air inlet and surge boundary conditions, and achieve the effects of not easy to deviate, increase surge margin, and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further explained in conjunction with the accompanying drawings.

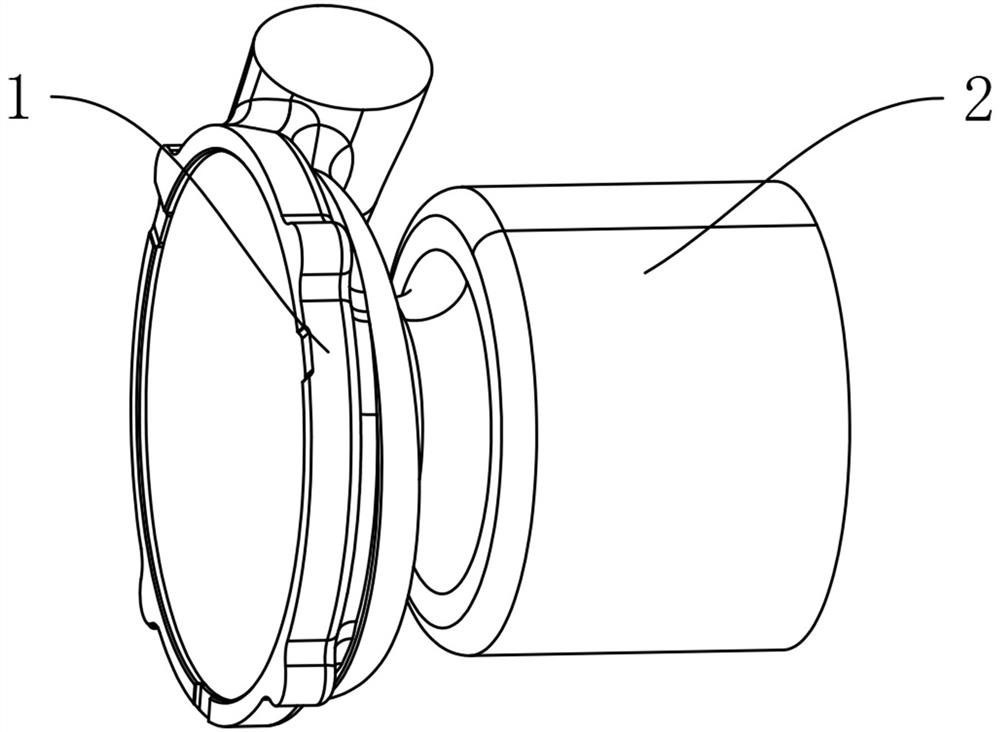

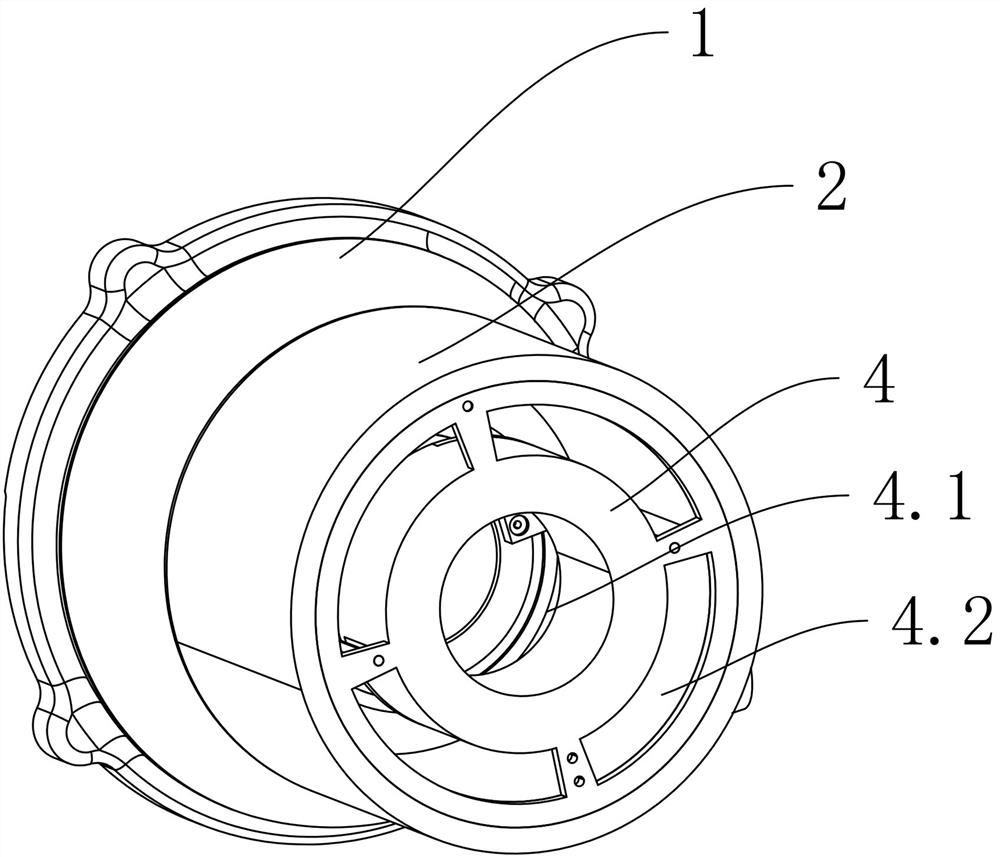

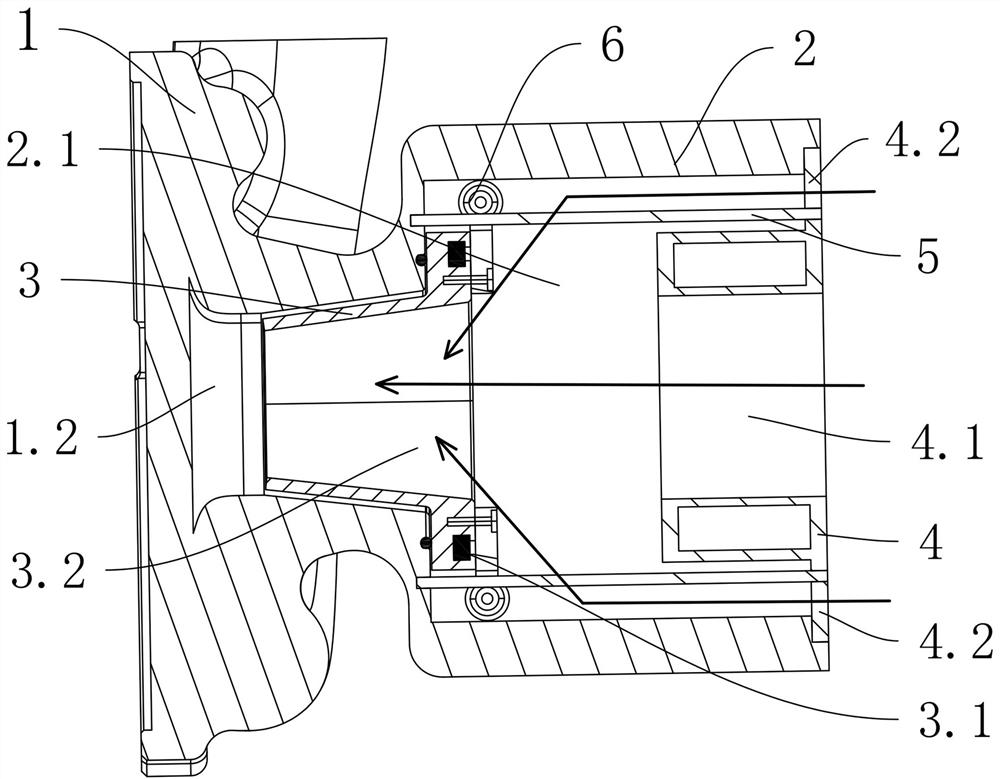

[0023] see Figure 1 to Figure 5 The shown air intake adjustment mechanism includes a housing 1, an adjustment element 3 and an electromagnetic drive assembly for driving the adjustment element 3, and a position corresponding to the compressor impeller air inlet 1.2 is set in the housing 1. There is an air intake cavity 1.1, the air intake cavity 1.1 is in the shape of a bell mouth, the housing 1 has a mounting part 2 extending along the axial direction of the housing, the mounting part 2 has a mounting part inner cavity 2.1, and the mounting part 2 is connected to the The housing 1 is integrally formed, and the cross-sectional area of the air intake chamber 1.1 increases gradually toward the mounting portion 2 in the axial direction.

[0024] The electromagnetic drive assembly is arranged at the inner cavity 2.1 of the installation part, the adjusting element 3 is in the shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com