Dry mounting system and method for ultra-thin wall veneers

A technology for installing systems and decorative panels, applied in covering/lining, construction, building construction, etc., can solve the problems of large limitations, high cost, inconvenient installation, etc., and achieve fast installation speed, large leveling range, and occupation small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

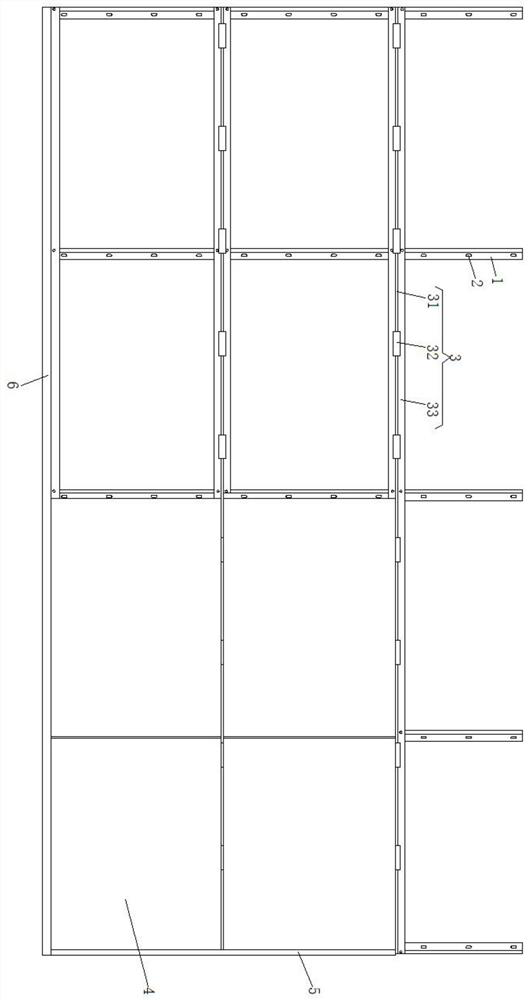

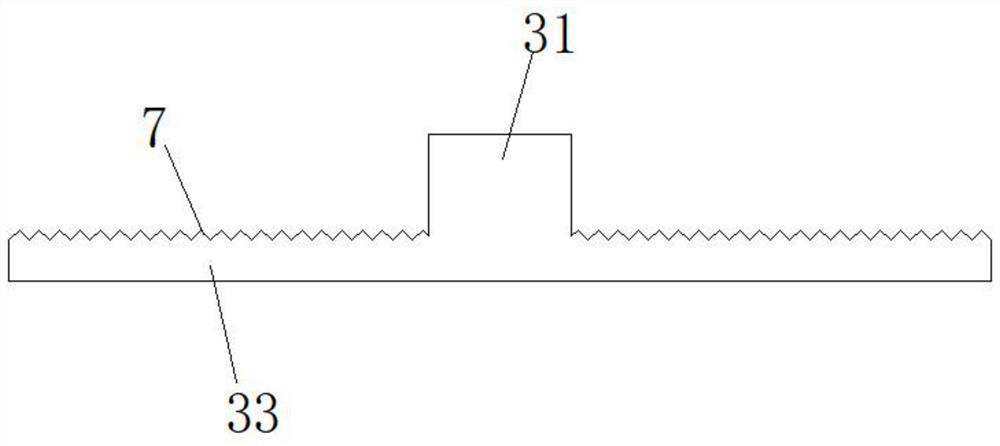

[0033] For a specific implementation, please refer to Figure 1-2 , the present invention provides a technical solution: enumerating a specific embodiment, a dry installation system for ultra-thin facing wall panels, including first keel frames 1 arranged vertically at equidistant distances, equidistant on the first keel frames 1 A leveling hole 2 for connecting with the wall is opened, and a second keel 3 arranged horizontally is fixed equidistantly from top to bottom between the first keel frames 1 , and the second keel 3 includes a bottom plate 33 and a bearing formed in the middle of the bottom plate 33 The platform 31 and the middle part of the bottom plate 33 are provided with through holes 32 at equal distances. Use a leveler to pass through the leveling hole 2 of the first keel frame 1 or the through hole 32 of the second keel 3 to level the plate 4. The plate seam adopts a cross etc. board seam tool control, wherein the board seams are filled with caulking agent, a T-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com