High-temperature compressed air cooling and purifying system and using method thereof

A compressed air and purification system technology, applied in chemical instruments and methods, separation methods, damage protection, etc., can solve problems such as poor water removal and purification effects, filter blockage, safety production impact, etc., and achieve water cooling and impurity filtering effects Good, prevents filter clogging, and prevents malfunctions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

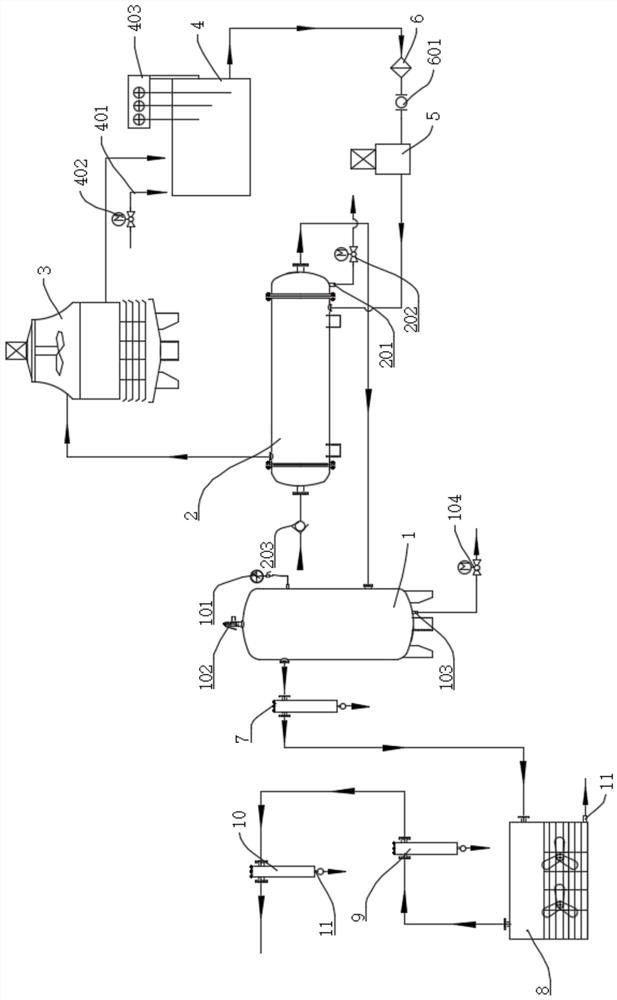

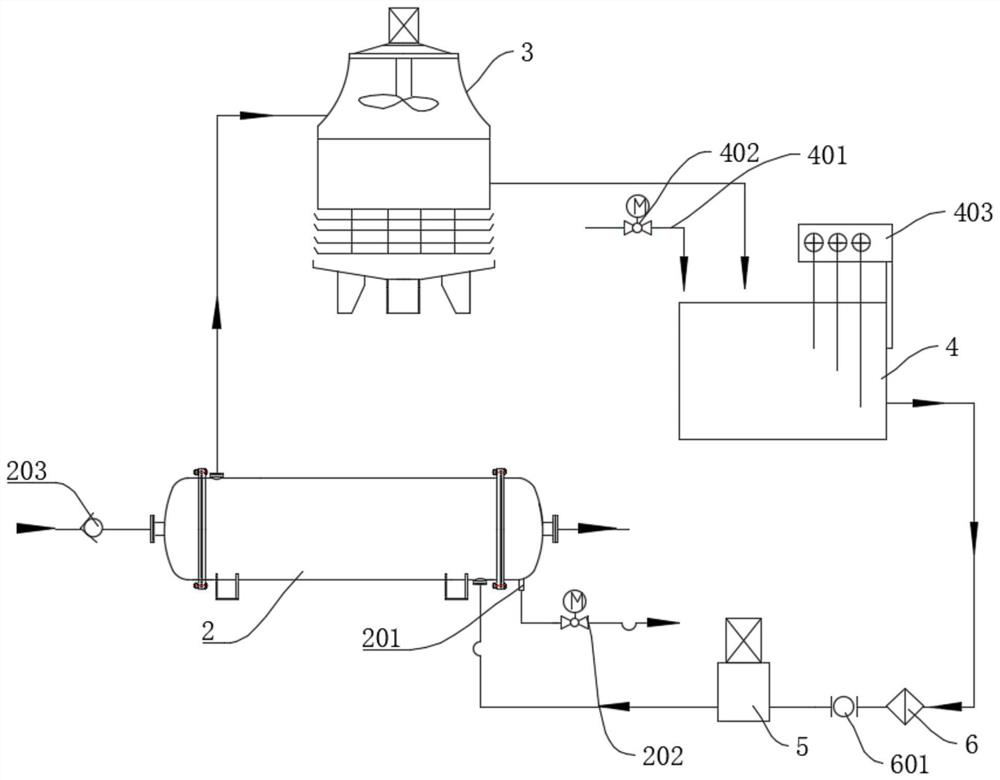

[0024] refer to figure 1 , figure 2 , a high-temperature compressed air cooling and purification system, including a primary cooling device, an air storage tank 1 and a secondary cooling and filtering device, the air outlet of the primary cooling device is connected to the air storage tank 1, and the air outlet of the air storage tank 1 is connected to the secondary Cool filter unit.

[0025] Among them, the primary cooling device includes a heat exchanger 2, a cooling tower 3, a water storage tank 4 and a pipeline pump 5, the heat exchanger 2 is a straight tube heat ex...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap