Control valve comprising a sealing contour on a sleeve-shaped hydraulic guide element, and component comprising a control valve and camshaft phaser

A technology of guiding components and control valves, which is applied to engine components, valve devices, machines/engines, etc., and can solve problems such as difficult adjustment of control pistons, control valve leaks, and blockages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

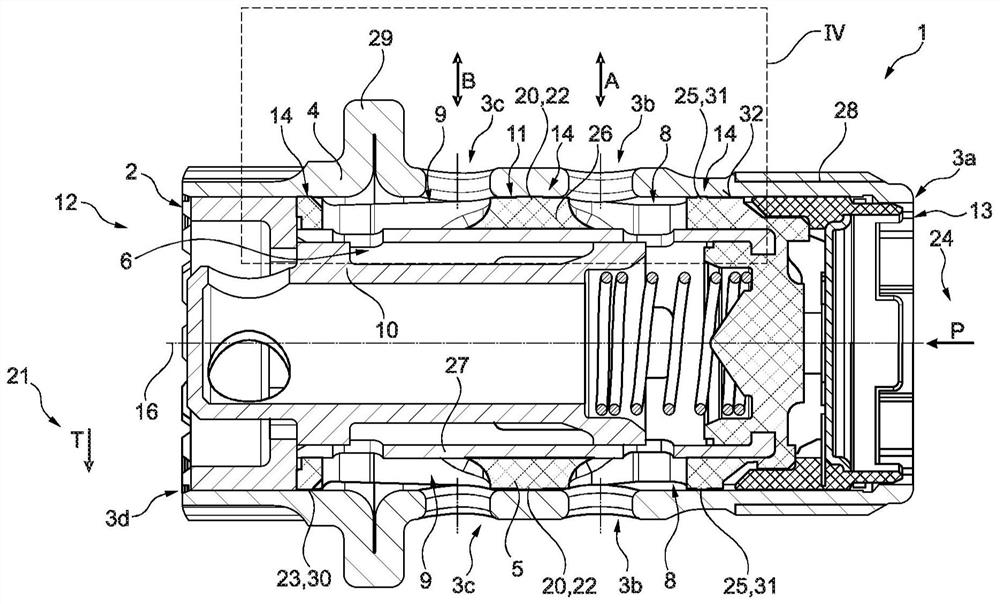

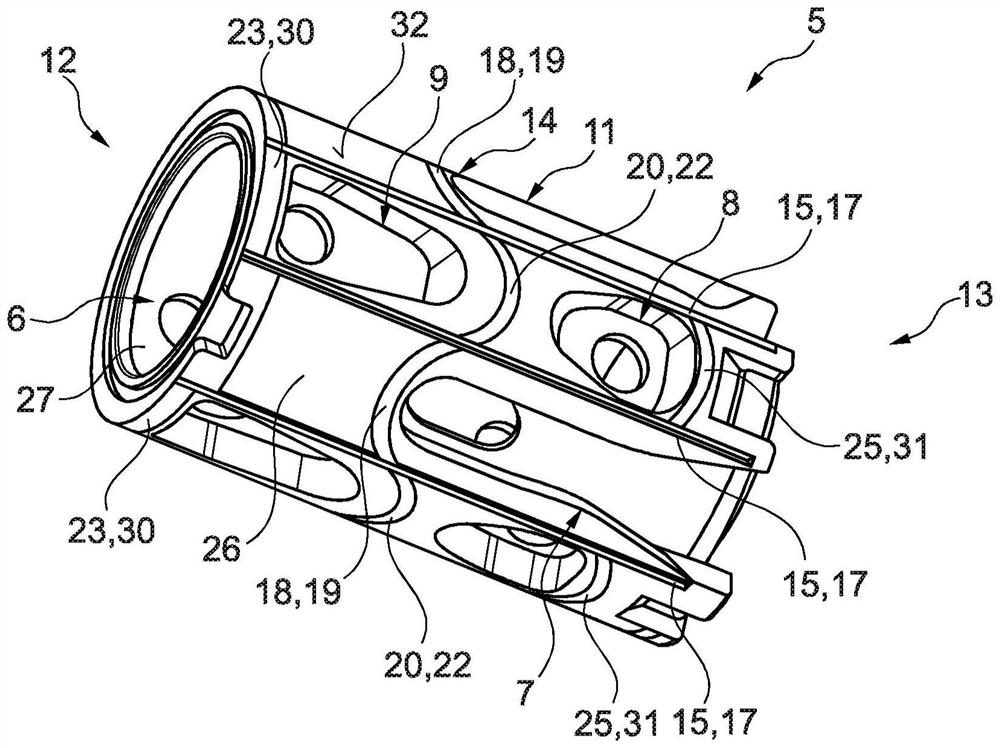

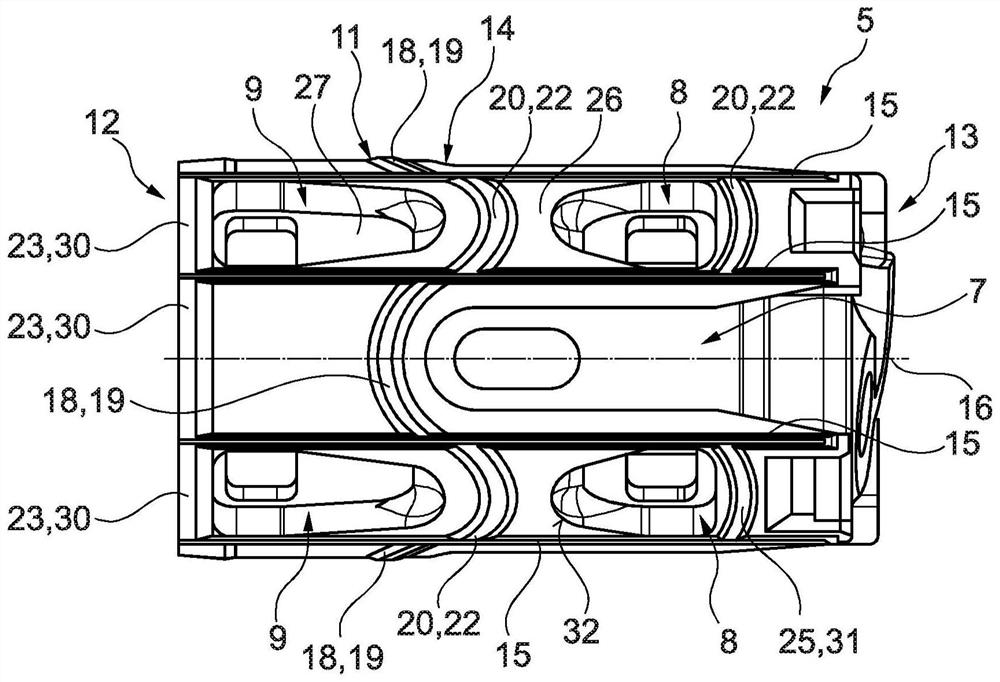

[0032] figure 1 The control valve 1 according to the invention is shown in its basic construction. The control valve 1 is generally designed as a central valve and, when used to control a hydrodynamic camshaft phaser, is correspondingly inserted radially into the rotor of the camshaft phaser. The control valve 1 thus forms a plurality of connections 3a, 3b, 3c, 3d which, during operation, are hydraulically connected to the inlet 24 (P corresponds to the pump side), the outlet 21 ( T corresponds to the tank side) and working chambers A, B. Different states of the camshaft phaser are generally achieved during operation depending on the position of the control piston 10 of the control valve 1 .

[0033] The control valve 1 has a hollow formed screw body 4 with connection portions 3a to 3d which, during operation, are screwed onto corresponding receptacles on the camshaft, thereby attaching the rotor of the camshaft phaser to the camshaft . Thus, among other things, the radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com