Rotary automatic purging emulsion filter

A filter and emulsion technology, applied in the direction of mobile filter element filter, filtration separation, chemical instruments and methods, etc., can solve the problem of furnace wall and flue polluting the atmospheric environment, non-renewable energy utilization, and waste gas difficult to recycle, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

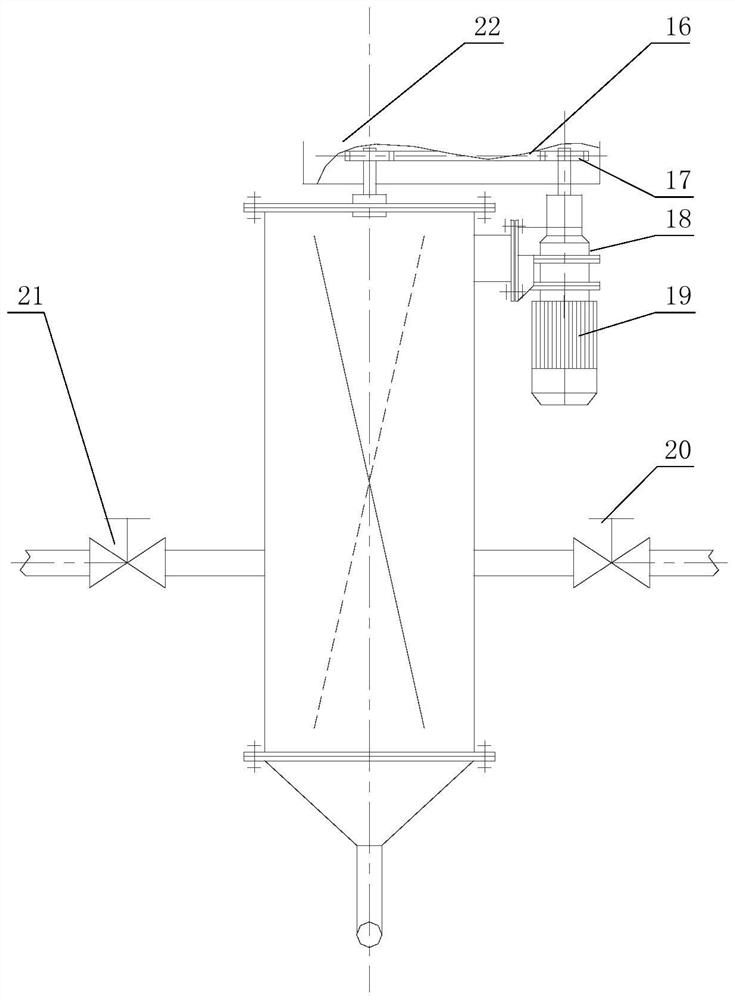

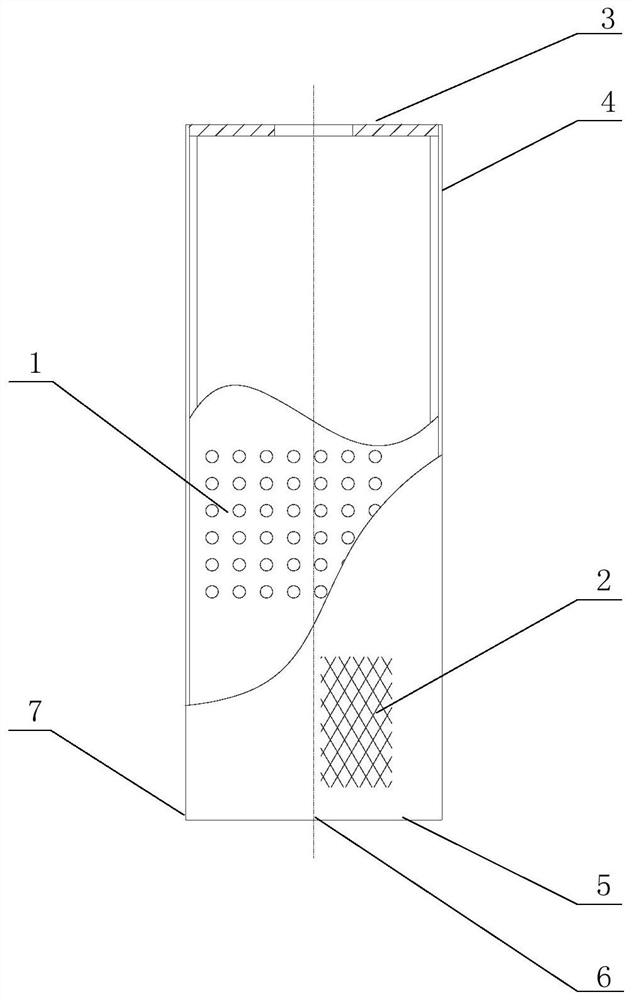

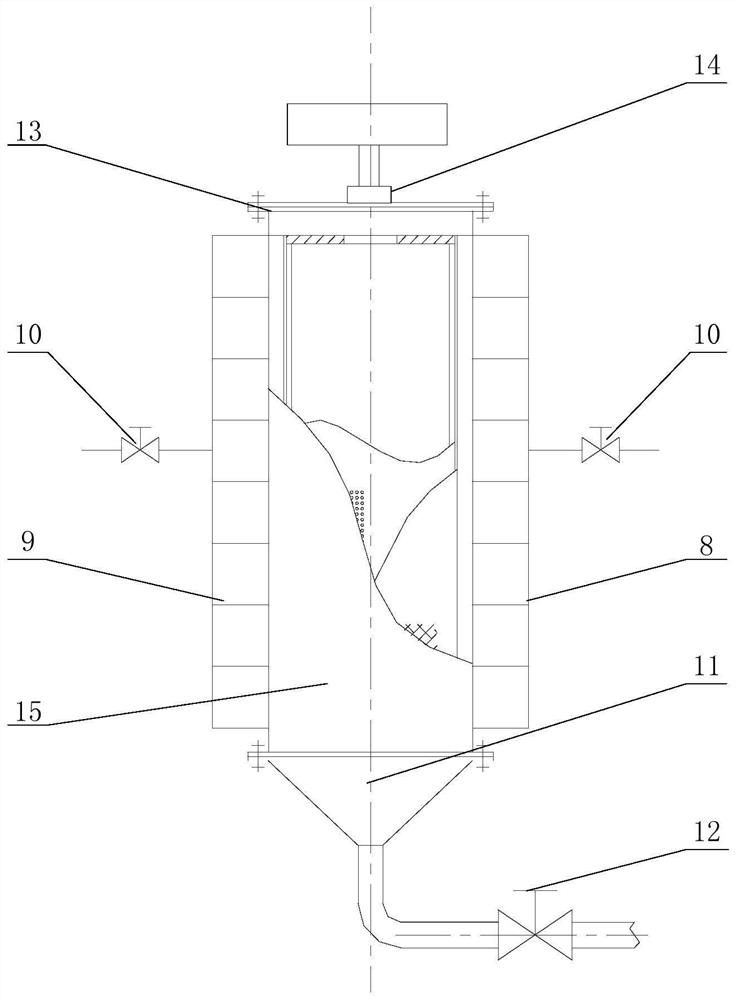

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] Due to the complex composition and high viscosity of the discarded emulsion, sometimes it exists in the liquid in the form of flocs, and it will condense into a paste when it encounters low temperature in winter. Therefore, the emulsion must be strictly filtered before entering the treatment. Otherwise, if the emulsion impurities enter the system, the system's instruments, oil guns, valves and pipelines will be blocked. After filtering for a period of time, the impurities adhering to the filter net will accumulate more and more, the resistance will increase, and the current of the oil pump will also increase. It is necessary to call the police in time and use steam to blow off the impurities adhering to the filter net. In the dirty oil pool, after a period of purging and cleaning the filter, return to the emulsion deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com