An automatic bearing pressing equipment

A bearing and automatic technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of large manual labor and manual operation, and achieve the effect of reducing labor and expanding the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1-6 The application is described in further detail.

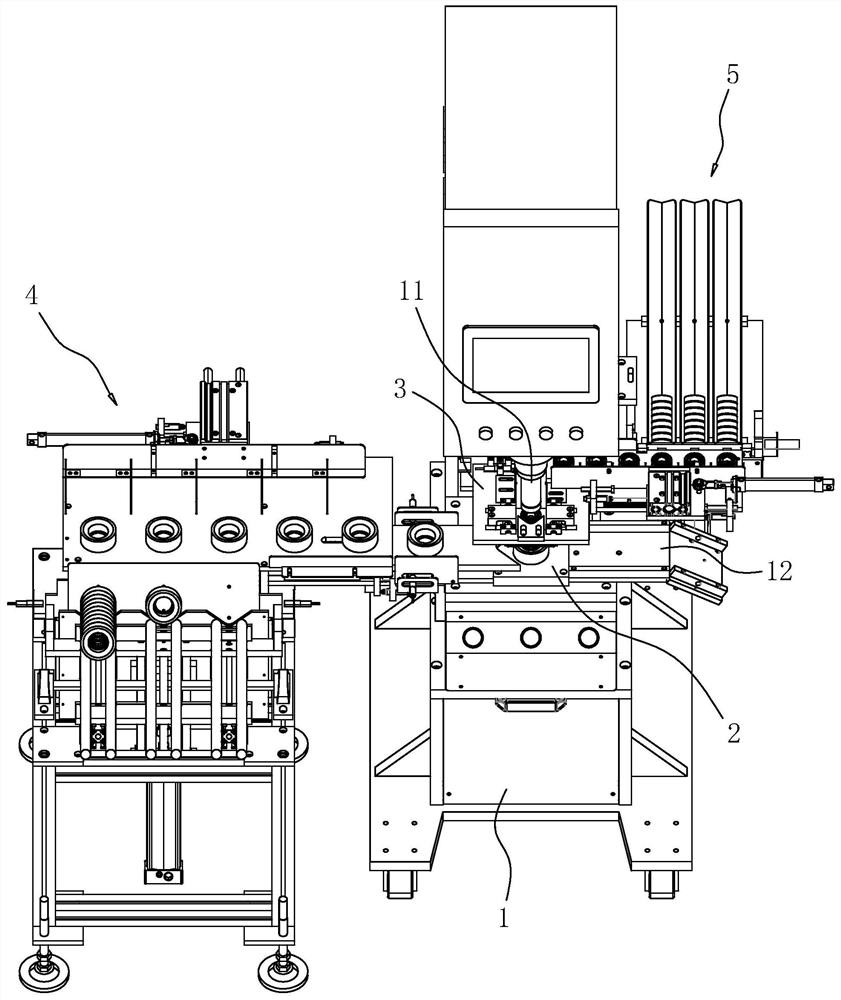

[0039] The embodiment of the present application discloses an automatic bearing pressing equipment. refer to figure 1 The automatic bearing press-fitting equipment includes a frame 1, a workbench 2 for placing workpieces, an indenter 11 driven and slid by a driving source, the indenter 11 faces the workbench 2, and a middle is provided between the indenter 11 and the workbench 2 Platform 3 and intermediate platform 3 are used to place bearings. The press-fitting equipment also includes a feeding mechanism 1 for loading workpieces, a feeding mechanism 2 5 for loading bearings, and a frame 1 next to the workbench 2 is provided for unloading the pressed workpieces. The feeding channel 12.

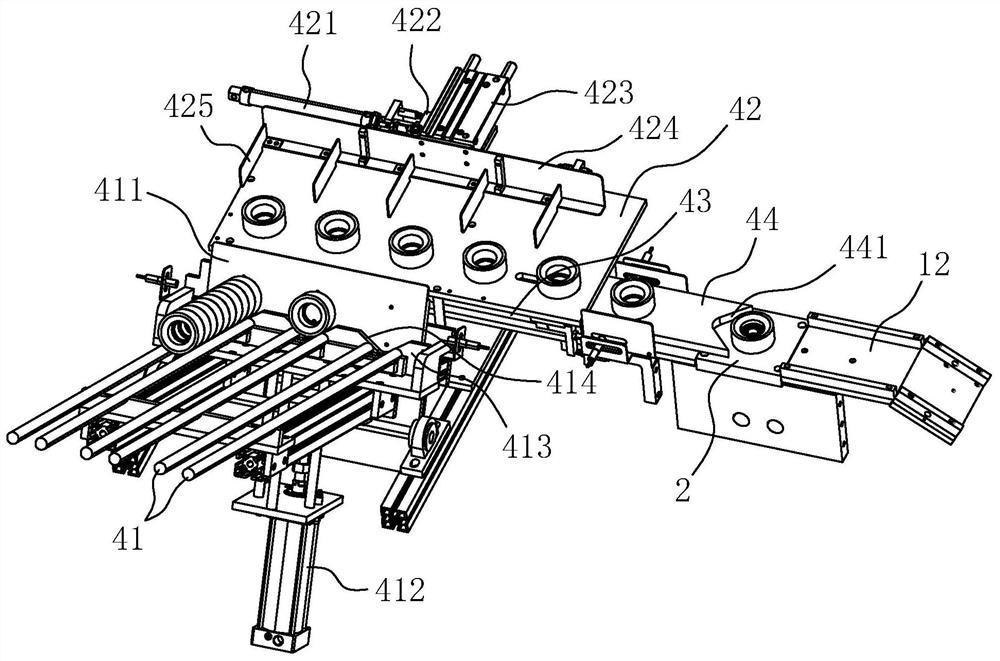

[0040] refer to figure 2 and image 3, feeding mechanism one 4 comprises material rack 41, feeding table 42, and wherein feeding table 42 is positioned at the side of workbench 2 horizontal di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com