Anti-deformation cutting device for corrugated board

A corrugated cardboard and anti-deformation technology, which is applied in metal processing and other directions, can solve the problems of poor overall effect, uneven end surface, deformation, etc., and achieve the effect of easy subsequent splicing, perfect overall function, and smooth cutting end surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

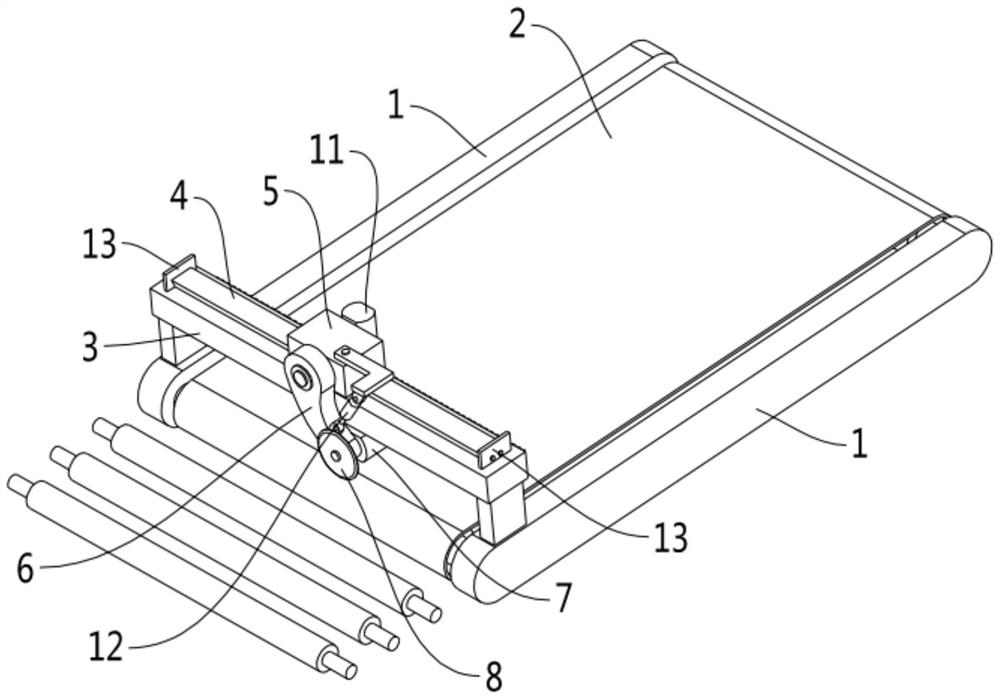

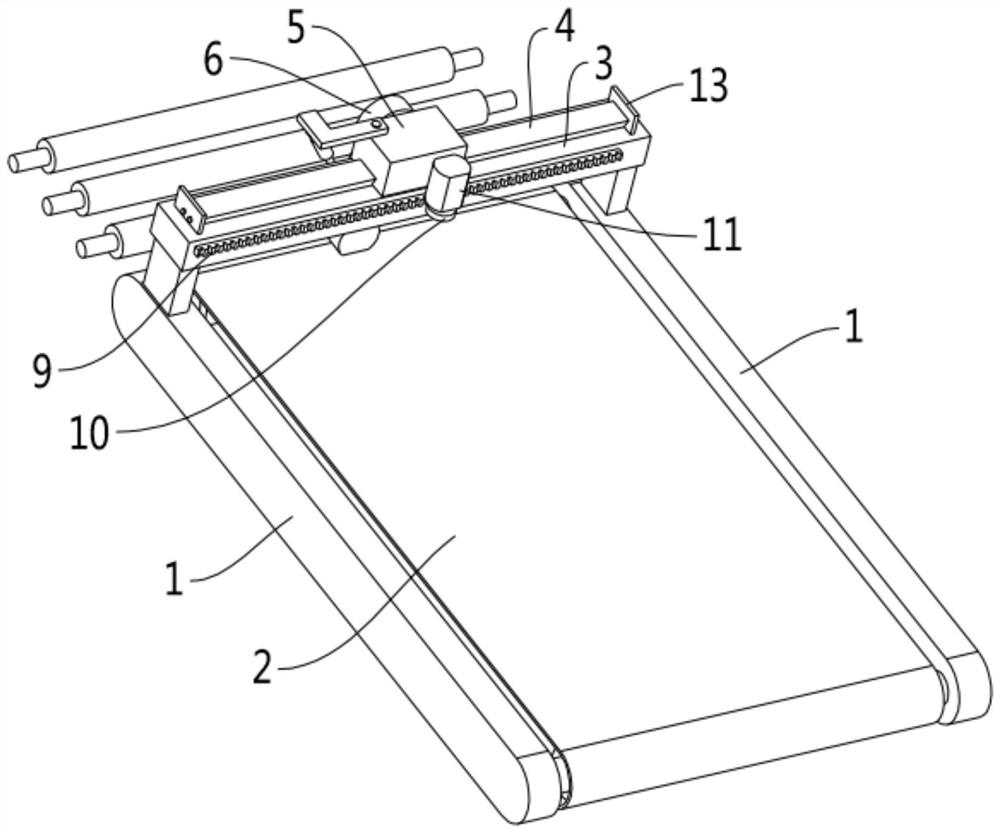

[0016] see figure 1 and figure 2 As shown, the anti-deformation cutting device for corrugated cardboard involved in this embodiment includes two side frames 1 arranged symmetrically on the left and right, and a driving roller and a driven roller are rotatably connected between the side frames 1. The roller and the driven roller are connected with a conveyor belt 2, and a beam 3 is arranged above the conveyor belt 2, and the beam 3 is close to the input end of the conveyor belt 2, and a sliding slide extending horizontally on the beam 3 rail 4, slide rail 4 is slidably connected with a moving seat 5, a swing arm 6 is rotatably connected with the moving seat 5, a first motor 7 is arranged on the swing arm 6, and a circular saw is arranged on the output shaft of the first motor 7 8, the beam 3 is also provided with a rack 9 extending horizontally left and right, a gear 10 is meshed on the rack 9, a second motor 11 with an output shaft connected to the gear is provided on the mo...

Embodiment 2

[0021] see Figures 1 to 3 As shown, the anti-deformation cutting device for corrugated cardboard involved in this embodiment, on the basis of Embodiment 1, is further set up as follows: the two sides of the conveyor belt 2 are respectively provided with rotating connections Guide wheel 14 on the side frame 1. Through the setting of the guide wheel 14, it plays a role of laterally guiding the cut corrugated cardboard.

[0022] Further, a positioning assembly 15 is provided between two adjacent guide wheels 14 on the same side frame 1; the positioning assembly 15 includes a fixed block 151, and a guide rod 152 is slidably connected to the fixed block 151, and one end of the guide rod 152 is provided with a limiter. The other end of the position part 153 is provided with a movable block 154 , and the guide rod 152 is sleeved with a compression spring 155 which abuts against the fixed block 151 at one end and abuts against the movable block 154 at the other end. Through the set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com