Unit cell and manufacturing method therefor

A cell and cell manufacturing technology, applied in the field of manufacturing the cell cell, can solve problems such as resistance increase, and achieve the effects of easy stacking, stacking, and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

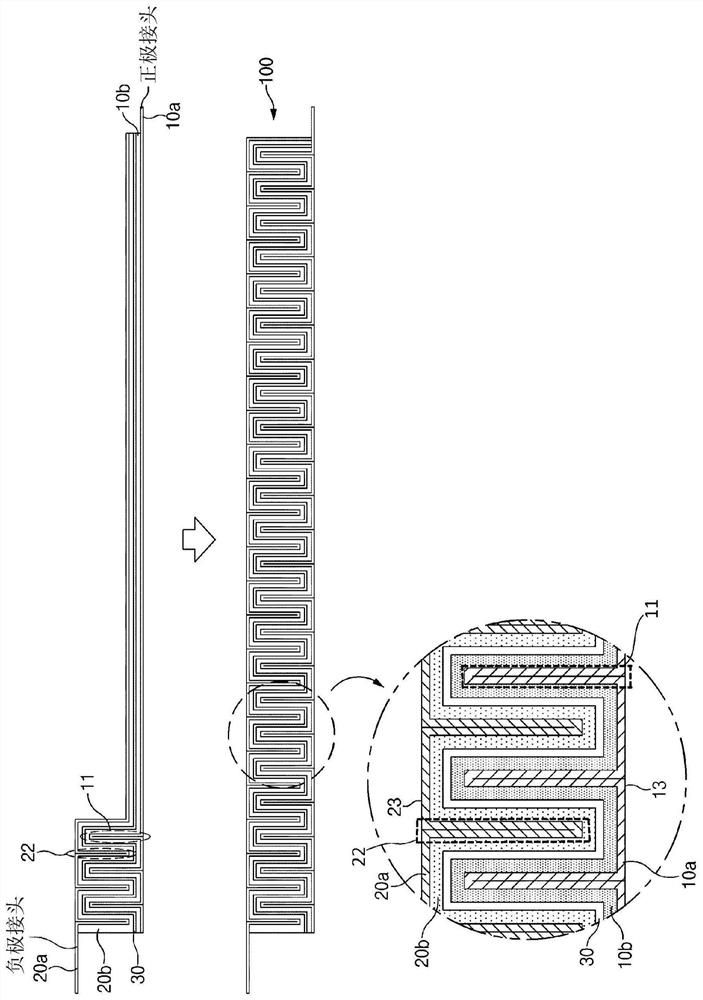

[0038] A method for manufacturing the unit cell 100 in which the distance between the positive electrode current collector 10 a and the negative electrode current collector 20 a is minimized will be described according to the first embodiment.

[0039] figure 2 are side views showing states before and after stacking the positive electrode 10 , the separator 30 , and the negative electrode 20 according to the present invention. image 3 is a side view showing a state where a positive electrode, a separator, and a negative electrode are stacked and then folded in a zigzag shape to form wrinkles thereafter.

[0040] refer to figure 2 and image 3 , in the manufacturing method according to the present embodiment, a single-sided positive electrode and a single-sided negative electrode are provided. That is, the manufacturing method according to this embodiment of the present invention includes the step of applying the positive electrode active material 10b to one surface of th...

no. 2 approach

[0052] According to the second embodiment, the unit cell 100 in which the distance between the positive electrode current collector 10 a and the negative electrode current collector 20 a is minimized will be described.

[0053] The unit cell 100 according to the present invention has a feature that the negative electrode 20 , the separator 30 and the positive electrode 10 are stacked one by one and then continuously folded in a zigzag shape to form a plurality of folds.

[0054] In the positive electrode, the positive electrode active material 10b is applied to only one surface of the positive electrode current collector 10a, and in the negative electrode 20, the negative electrode active material 20b is applied to only one surface of the negative electrode current collector 20a. The cathode 10 and the anode 20 are stacked such that the cathode active material 10b and the anode active material 20b face each other with the separator 30 therebetween. Here, each of the positive e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com