Pipeline system with refrigeration and pasteurization functions, refrigerator and ice cream machine

A pasteurization, ice cream machine technology, applied in the pipeline system, refrigerator, ice cream machine field, can solve the problems of incomplete cleaning, affecting human health, bacteria breeding in equipment, etc., to achieve the effect of ingenious design, safe use, and prevention of bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0076] The following will combine the drawings in the embodiments of the present invention; clearly and completely describe the technical solutions in the embodiments of the present invention; obviously; the described embodiments are only a part of the embodiments of the present invention; rather than all the embodiments, based on The embodiments of the present invention; all other embodiments obtained by those of ordinary skill in the art without creative work; all belong to the protection scope of the present invention. Example 1:

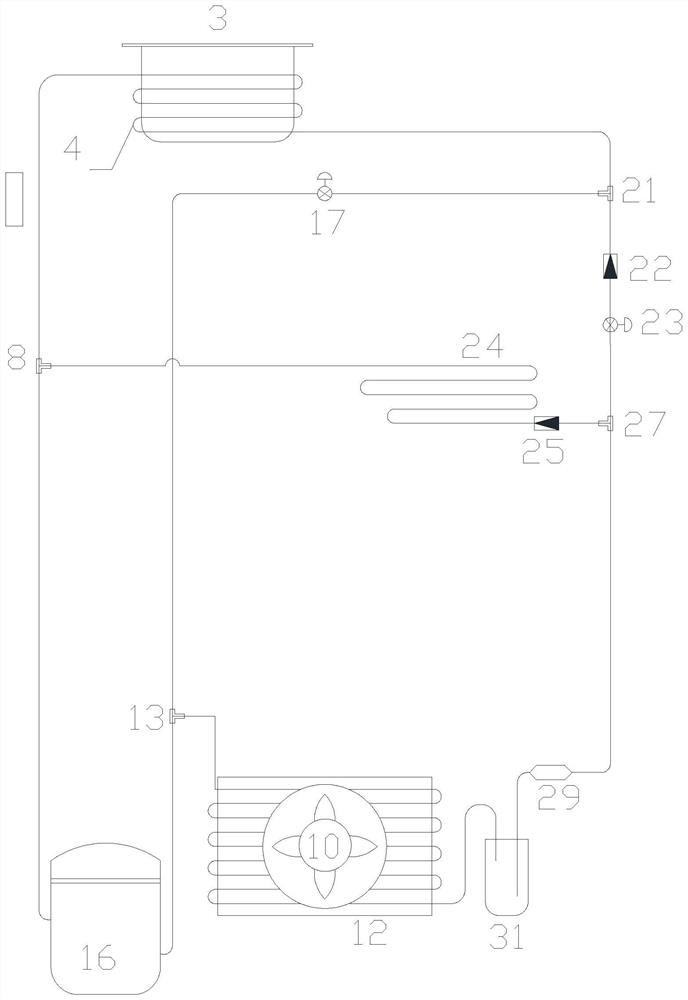

[0077] like Figure 1-8 As shown, the pipeline system with both refrigeration and pasteurization functions includes a compressor 16, a condenser 12, a liquid accumulator 31, a first container 3, a first heat exchanger 4, a first solenoid valve 17, a first Expansion valve 22, second solenoid valve 23, constant pressure heat exchanger 24, evaporation pressure regulating valve 25, filter drier 29, first pipeline node 8, second pipeline node 13, thi...

Example Embodiment

[0081] Example 2:

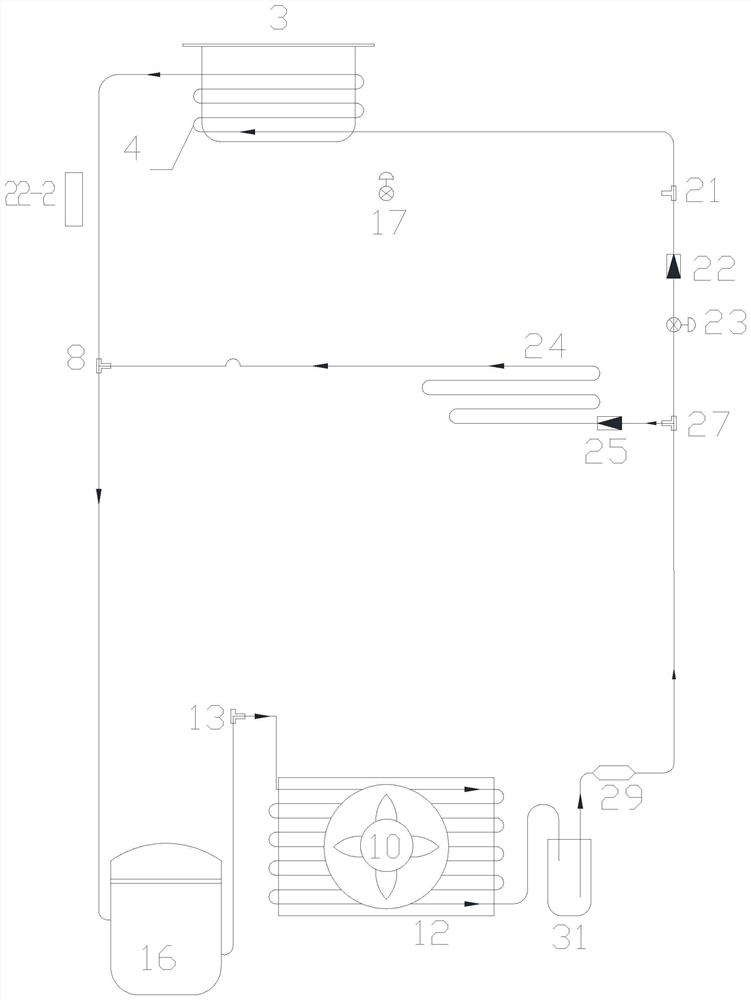

[0082] like Figure 9 As shown, on the basis of Example 1, a pipeline with both refrigeration and pasteurization functions is included

[0083] The system of the refrigerator also includes a control module. The compressor 16 has an electrical connection with the control module, the first solenoid valve 17 has an electrical connection with the control module, and the second solenoid valve 23 has an electrical connection with the control module, and the control module controls the compressor 16, the first solenoid The valve 17 and the second solenoid valve 23 work. When the refrigeration function is turned on, the control module blocks the fluid passage of the first solenoid valve 17 and opens the fluid passage of the second solenoid valve 23 . When the pasteurization function is turned on, the control module opens the fluid channel of the first solenoid valve 17 and blocks the fluid channel of the second solenoid valve 23 . Among them, the first containe...

Example Embodiment

[0084] Example 3:

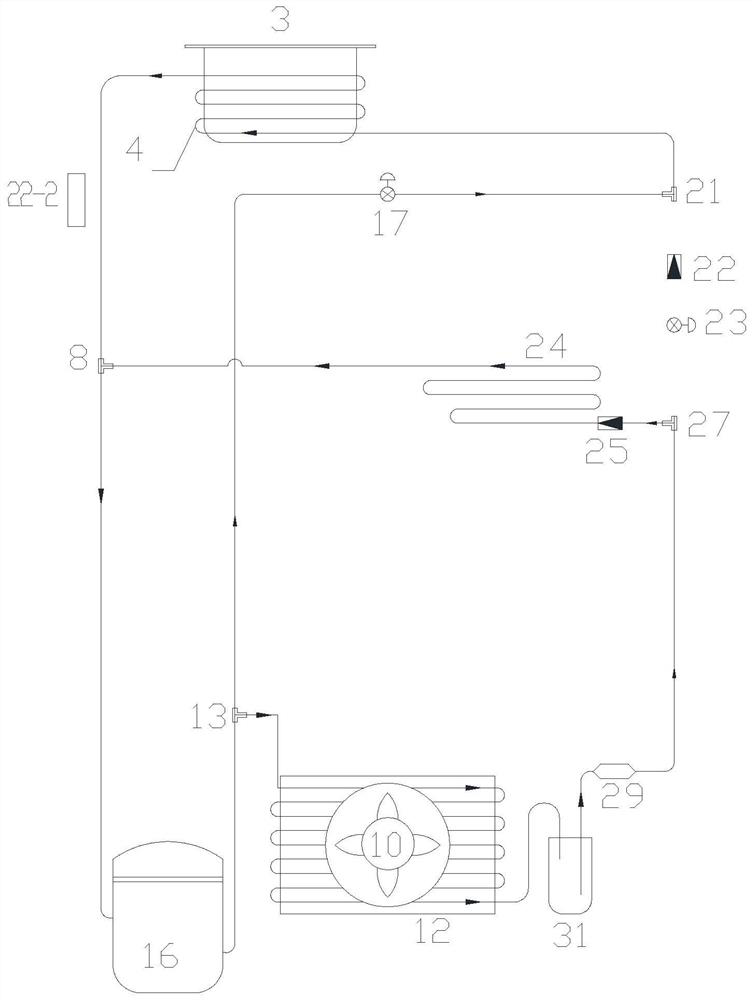

[0085] like Figure 10-13 As shown, on the basis of Example 1, it contains both refrigeration and pasteurization functions.

[0086] Ice cream maker with piping system. The first container 3 is a material storage container; it also includes a fifth pipeline node 1, a sixth pipeline node 11, a first freezing container 6, a seventh pipeline node 7, an eighth pipeline node 15, and a ninth pipeline node 30. The third solenoid valve 9, the fourth solenoid valve 28, the second expansion valve 26; the fifth pipeline node 1 is connected to the output end of the constant pressure heat exchanger 24, and the fifth pipeline node 1 is connected to the first pipeline node 8 is connected, the fifth pipeline node 1 is connected with the output end of the first freezing container 6; the sixth pipeline node 11 is connected with the first end of the first solenoid valve 17, and the sixth pipeline node 11 is connected with the second pipeline node 13 , the sixth pipeline no...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap