Method for preparing high-titer lentiviral vector by conventional centrifugation

A lentiviral vector and lentivirus technology, which is applied in the field of preparing high-titer lentiviral vectors, can solve the problems of increasing the cost of lentiviral vector equipment, expensive ultracentrifuges, etc., and achieve simple operation, increased yield and low preparation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: A method for preparing high-titer lentivirus products by conventional centrifugation, with a centrifugal force of 25,000 g, centrifuged for 10 hours, and concentrated 100 times. The steps are as follows:

[0021] (1) Preparation of lentivirus concentrate: take Tris-HCl solution, NaCl solution and EDTA solution with a pH of 7.4, and mix them according to the volume ratio of Tris-HCl:NaCl:EDTA=100:200:1 to obtain lentivirus concentrate, In the lentivirus concentrate, the concentration of Tris-HCl is 50mmol / L, the concentration of NaCl is 100mmol / L, and the concentration of EDTA is 0.5mmol / L;

[0022] (2) Prepare the virus extract: dissolve the sucrose solid with the lentivirus concentrate to obtain the virus extract, the mass volume concentration of sucrose in the virus extract is 0.1g / mL;

[0023] (3) Centrifugation: Add 10ml of virus extract to a centrifuge tube, then slowly add 40ml of lentivirus supernatant to the virus extract, put the centrifuge tube cont...

Embodiment 2

[0025] Example 2: A method for preparing high-titer lentivirus products by ultrahigh-speed centrifugation, with a centrifugal force of 70,000 g, centrifuged for 2 hours, and concentrated 100 times. The steps are as follows:

[0026] (1) Centrifugation: Take 40ml lentiviral supernatant exactly the same as in Example 1, add it to a centrifuge tube and put it into a centrifuge, select the operation mode with the slowest ascent and descent speed of the centrifuge to centrifuge the mixed solution, Centrifugal force 70000g, centrifuge at 20°C for 2 hours;

[0027] (4) Preparation of high-titer lentiviral vector: Remove the supernatant of the solution in the centrifuge tube after centrifugation, and then add 400ul lentivirus lysate (10mM Tris-HCl (pH8.0), 2mM MgCl2, 5 % sucrose) to dissolve the lentiviral pellet, and store in -80°C.

Embodiment 3

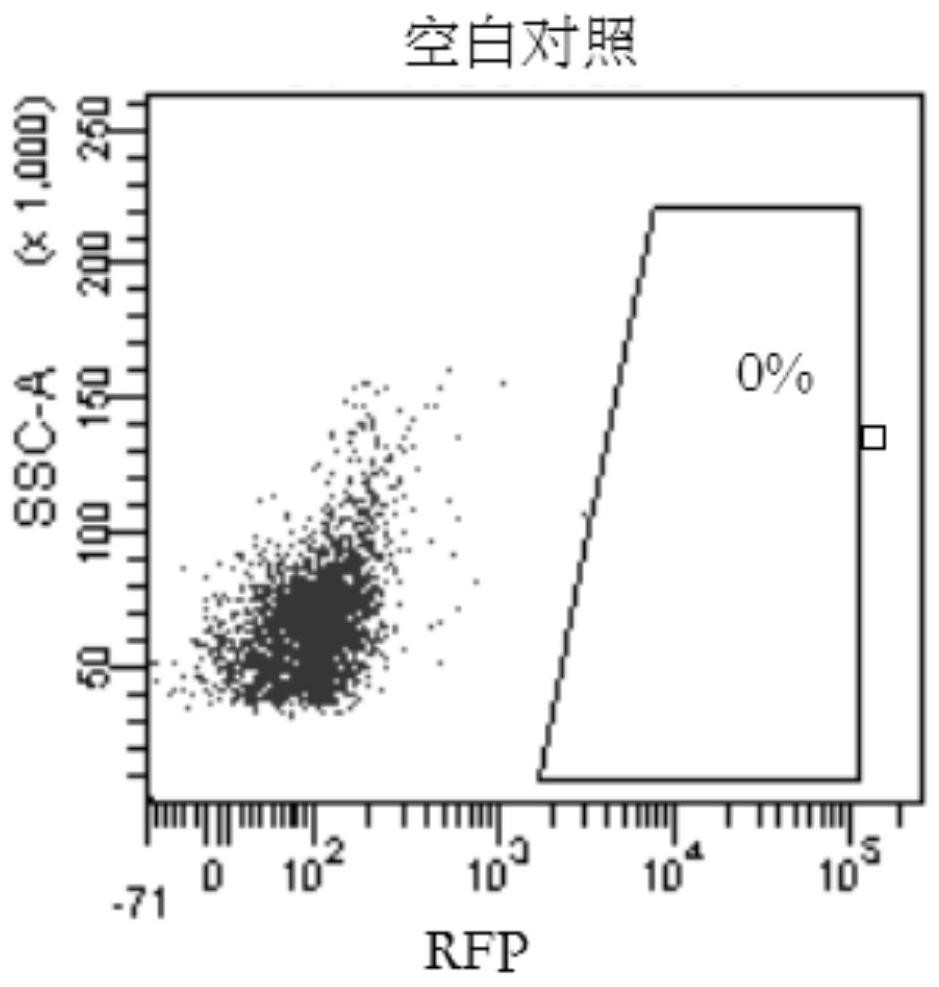

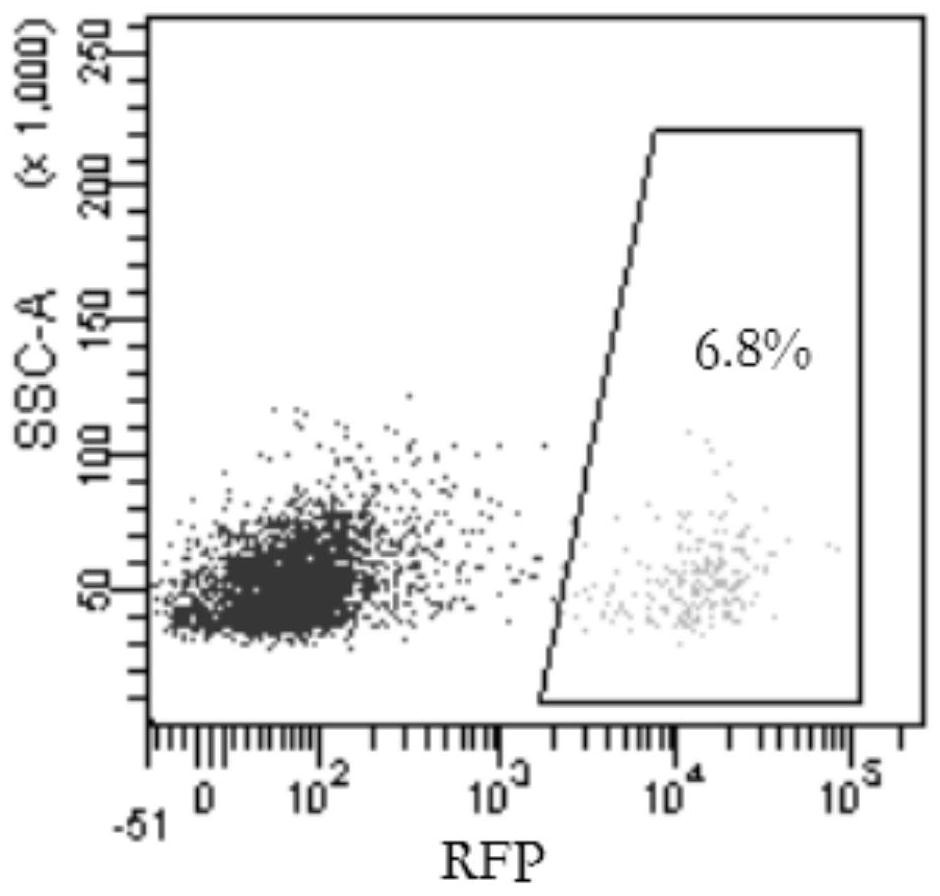

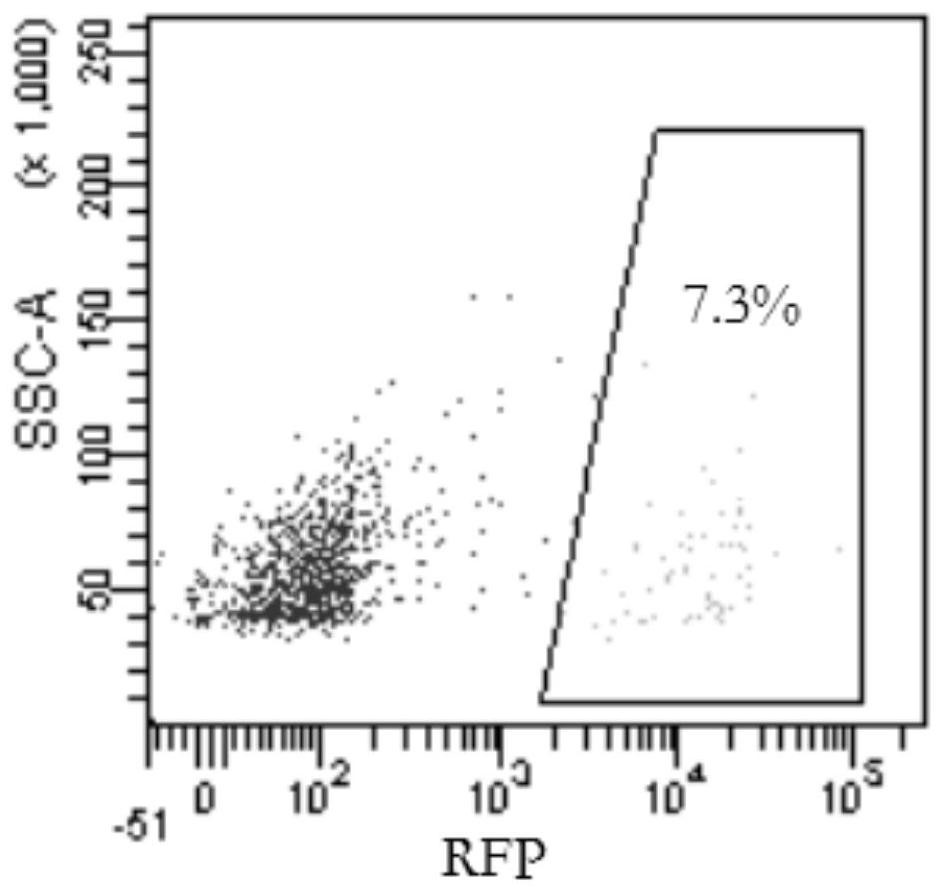

[0028] Embodiment 3: Titer determination

[0029] 1) Two 6-well plates were inoculated with 293T cells. 5×10 cells per well 5 For each, the volume of the medium added is 2ml, the growth rate of different types of cells is different, and the cell fusion rate during virus infection is 40%-60%;

[0030] 2) Prepare 6 sterile EP tubes, add 900ul of fresh complete medium (high sugar DMEM+10% FBS) to each tube; 24 hours after inoculating the cells, count the cells in two wells to determine the time of infection The actual number of cells, denoted as N;

[0031] 3) Take 100ul of the virus stock solution under different centrifugal force conditions (25000g and 70000g) and add it to the first tube, mix gently, then take 100ul and add it to the second tube, mix it and add it to the third tube middle;

[0032] 4) Add 100 ul of lentivirus at different dilutions to each well, remove the culture supernatant after 24 hours of infection, replace with 2 ml of complete medium (high sugar DME...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass volume concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com