Butt welding flange for steel pipe anticorrosive coating protection and construction method

A technology of anti-corrosion coating and welding flange, which is applied in the direction of flange connection, manufacturing tools, welding equipment, etc., can solve the problems of inability to achieve effective protection of plastic coating inside the pipeline, poor heat insulation performance, etc., and achieve the goal of reducing welding heat Transmission, low outer edge height, and the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

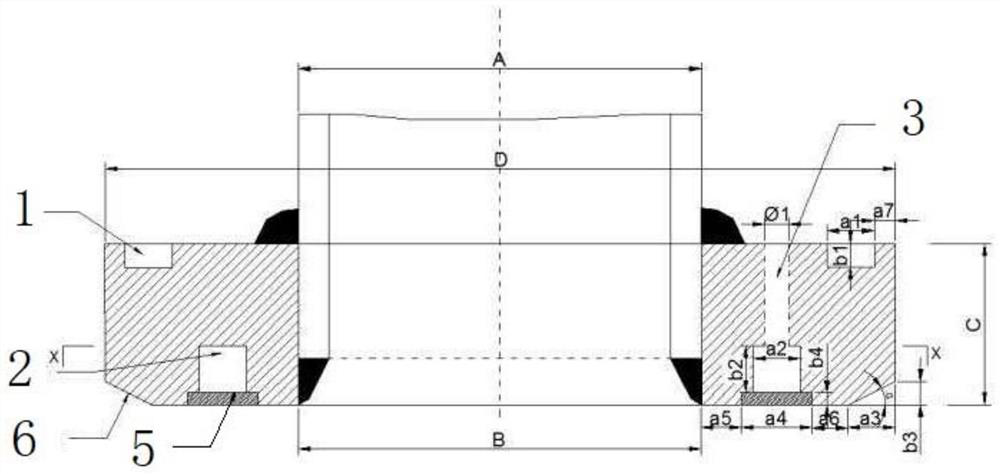

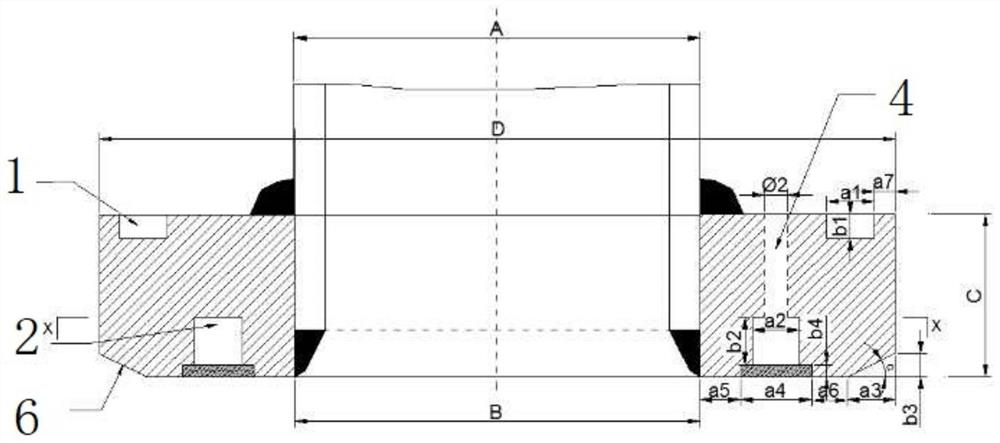

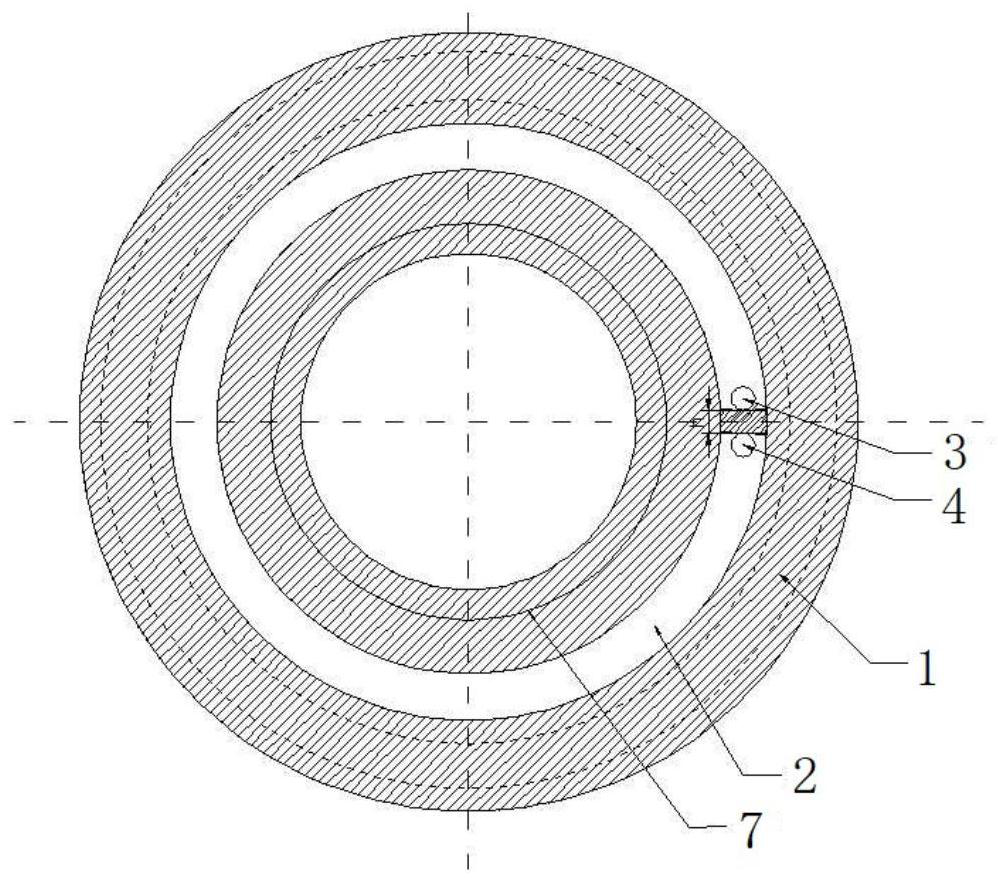

[0024] figure 1 , figure 2 , image 3 It shows a butt welding flange for steel pipe anti-corrosion coating protection. The shape of the right flange and the left flange are symmetrical. A rectangular heat sink 1 with an open top; the outer edge of the inner surface of the disk has a V-shaped groove 6 formed by splicing left and right flanges; the middle part of the inner surface of the disk has a rectangular or circular section. , the top opening of the annular apron groove, the rectangular apron 5 or circular apron is embedded in the above-mentioned annular apron groove, or, the annular iron plate seal is welded on the annular apron groove. The annular water circulation groove 2 with a rectangular cross section is located outside the annular rubber ring groove and directly communicates with the annular rubber ring groove, and there is a radial partition 2a on the annular water circulation groove 2, and the water inlet 3 and the outlet hole are respectively located on both ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap