Preparation method and processing equipment of nano instant brown sugar ginger tea powder

A technology of brown sugar ginger tea and processing equipment, which is applied in the direction of mixing methods, chemical instruments and methods, dissolution, etc., can solve the problems of insufficient mixing, long time consumption, and large limitations, and achieve improved mixing efficiency, sufficient material mixing, and improved The effect of mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

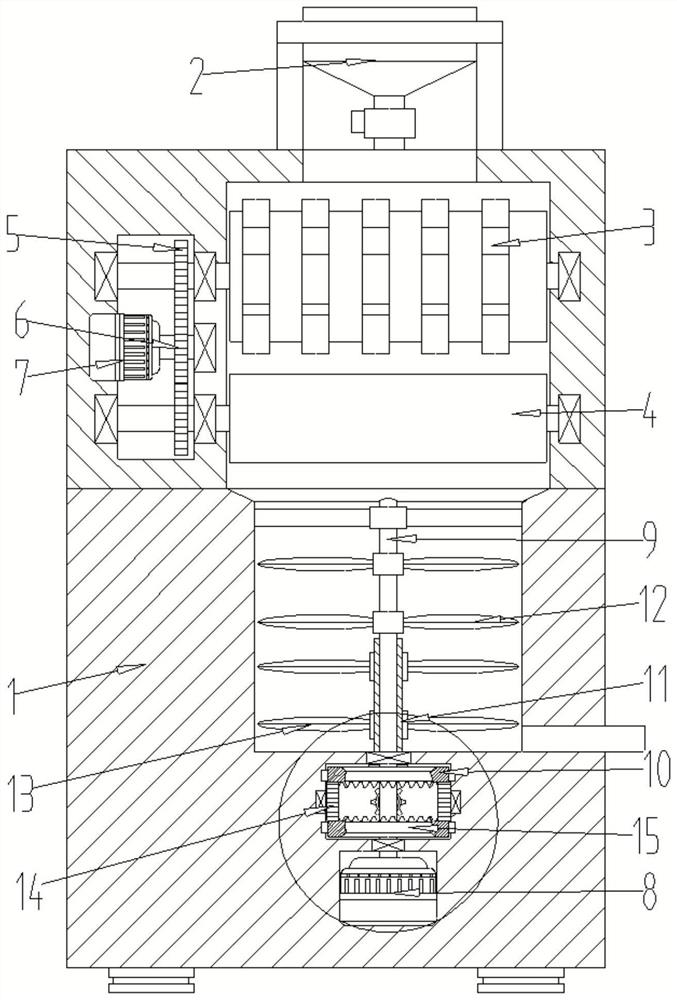

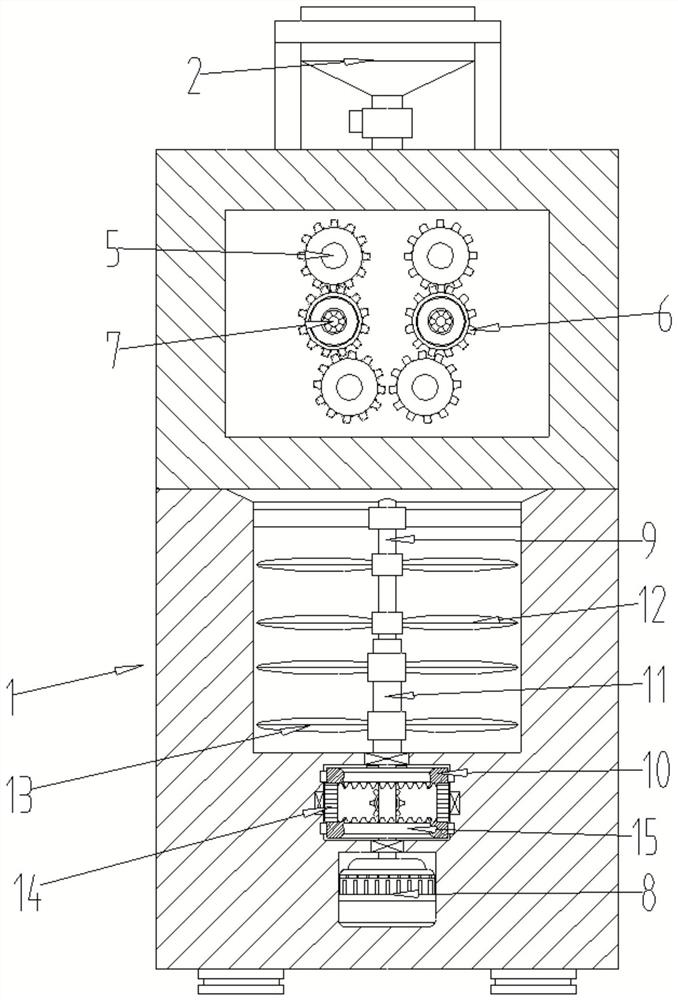

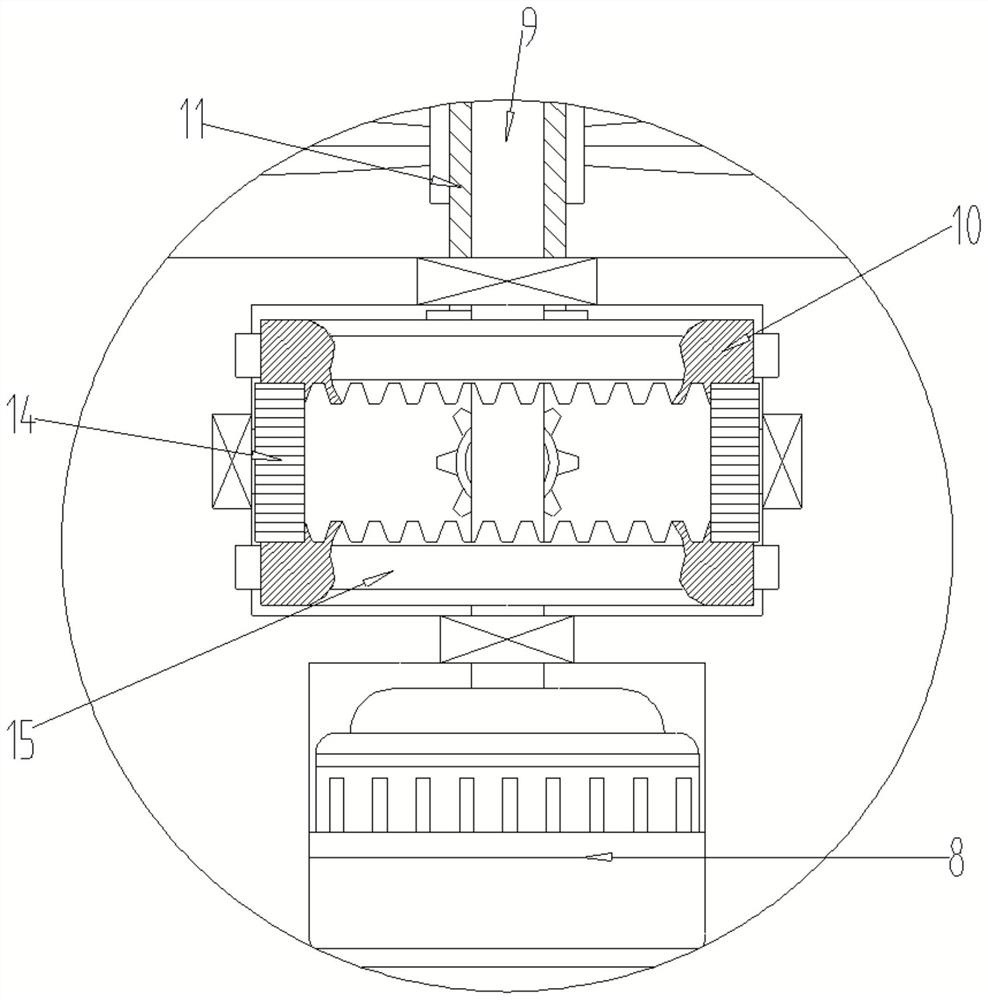

[0036] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, the preparation method of nanometer instant brown sugar ginger tea powder comprises: step S1, preparing main ingredient; step S2, heating and extracting; step S3, filtering; step S4, preparing microcapsules; step S5, concentrating; step S6, mixing Filling, step S7, reaction; step S8, drying; step S9, nanoscale grinding; the step S1: prepare black tea, ginger and jujube in proportion; the step S2: add pure Water, mixed, mixed evenly to obtain a mixture, and the obtained mixture was heated and extracted; the step S3: filtering the extract obtained in the step S2; the step S4: dissolving the composite wall material in pure water, and Add the filtrate obtained in step 3 after quality, and carry out ultrasonic embedding; the step S5: vacuum concentrate the microcapsule liquid obtained in the step S4; Add glucose, L-serine, L-threonine, L-alanine, and mix;...

Embodiment

[0053] Embodiment: the preparation method of nanometer instant brown sugar ginger tea powder, comprises: step S1, prepares major ingredient; Step S2, heat extraction; Step S3, filter; Step S4, prepare microcapsule; Step S5, concentrate; Step S6, mix Filling, step S7, reaction; step S8, drying; step S9, nanoscale grinding;

[0054] Step S1: Prepare black tea, ginger and red dates according to the proportion;

[0055] Step S2: adding pure water to the main material obtained in step S1, mixing, mixing evenly to obtain a mixture, and heating and extracting the obtained mixture;

[0056] Step S3: filtering the extract obtained in step S2;

[0057] Step S4: Dissolve the composite wall material in pure water, add the filtrate obtained in step 3 after homogenization, and perform ultrasonic embedding. The pure water in step S4 is 10% of the weight of the filtrate obtained in step S3. The composite wall material in step S4 is 3.2% to 5.2% of the weight of the filtrate obtained in step...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap