A chassis rocker arm part mold

A technology of parts and chassis, applied in the field of chassis rocker arm parts mold, can solve the problems of error, accumulated size, etc., and achieve the effect of avoiding accumulated error and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

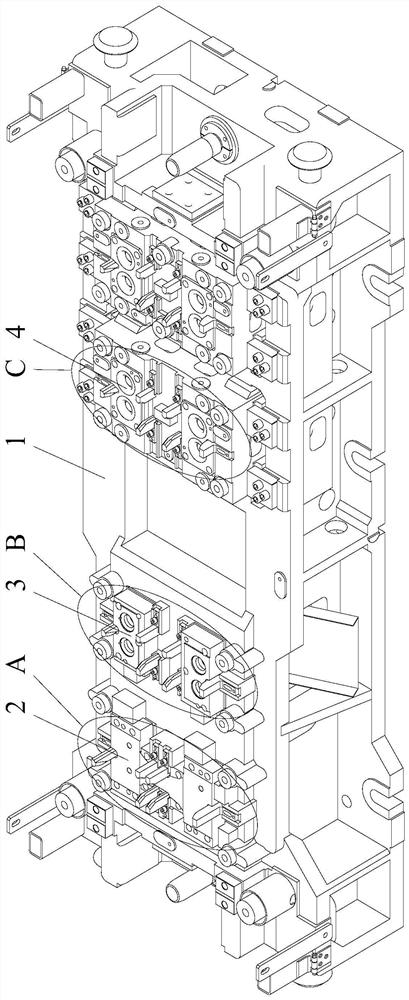

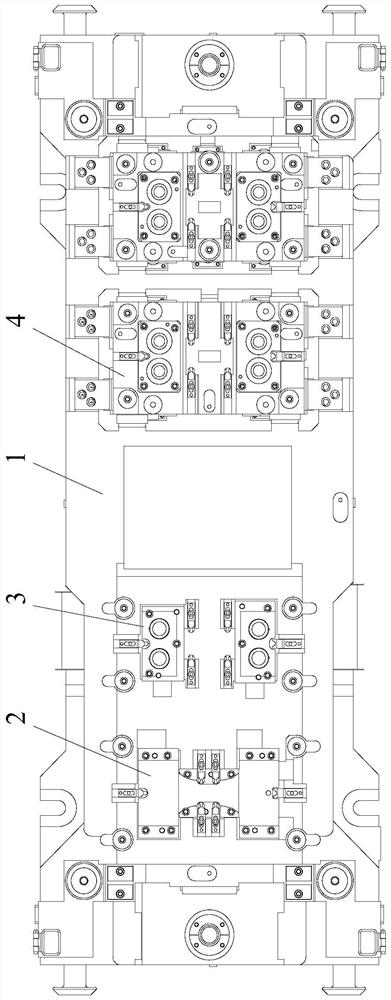

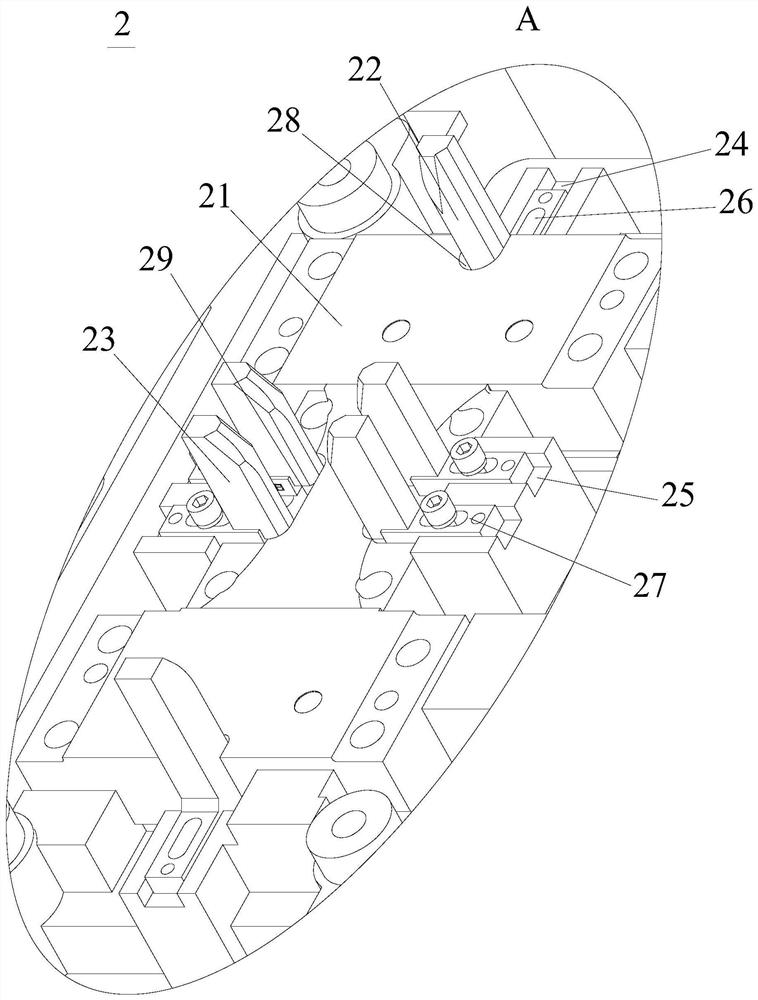

[0028] combine figure 1 and figure 2 As shown, the chassis rocker arm part mold disclosed in the embodiment of the present invention includes a mold base 1, a first module 2, a second module 3 and two third modules 4, a first module 2, a second module 3 and two third die sets 4 are fixed on the upper surface of the die base 1 in sequence along the length direction of the die base 1 at intervals. The length direction of the first module 2, the second module 3 and the two third modules 4 is perpendicular to the length direction of the mold base 1. The first module 2, the second module 3 and the two third modules The width direction of the group 4 is parallel to the length direction of the die base 1 . It should be noted that the two ends of the chassis rocker arm part in this embodiment are respectively provided with a groove and a convex edge, and the blanks of the chassis rocker arm part can be connected end-to-end in sequence during production, that is, the latter chassis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com