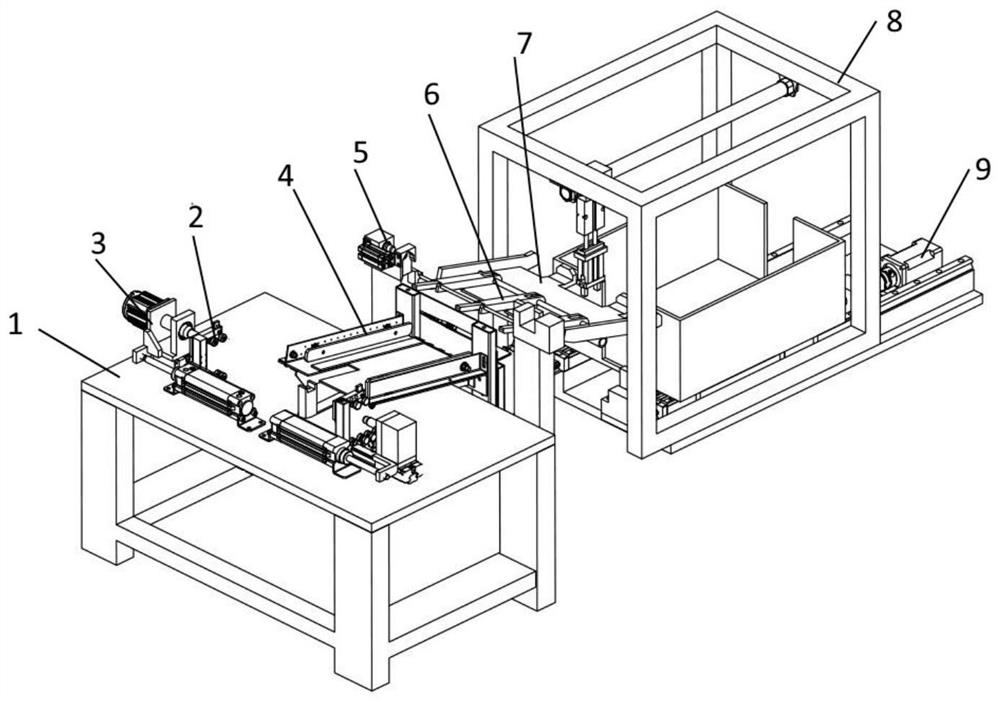

A polishing method based on a pipe inner wall polishing device

A technology for polishing devices and pipes, which is applied in the direction of grinding/polishing equipment, parts of grinding machine tools, and machine tools designed for grinding the rotating surface of workpieces. problem, to achieve the effect of collision avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] After the applicant's research and analysis, the reason for this problem (which will cause the polishing device to collide with the circular tube, and then cause damage to the polishing device) is that the existing polishing device needs to polish the inner wall of the circular tube. The inner wall of the round tube is inspected, and when the round tube is transported to the detection position, the round tube will deviate from the predetermined position, which will cause the polishing device to collide with the round tube, and the device will collide with the round tube during the transportation process. The collision between the tubes will cause the round tubes to be artificially damaged, which will increase the burden of detection work. In order to ensure that the circular tube can be located at the designated position, and then ensure the smooth progress of the detection work, the present invention is further equipped with a feeding assembly. Hold it and drive it to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com