Automatic fine and deep sorting method and device for power batteries

A power battery and sorting device technology, which is applied in battery recycling, solid waste removal, waste collector recycling, etc., can solve the problems of backward technology and inability to sort, and achieve the effect of low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

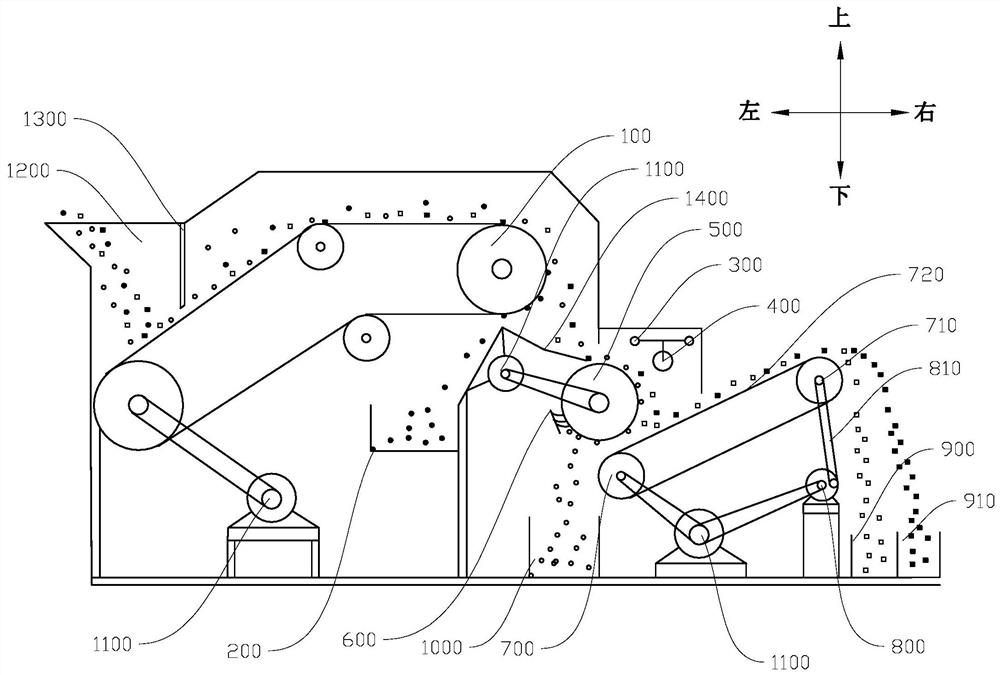

[0054] Example 1

[0055] A method for automatic and deep sorting of power batteries, comprising the following steps:

[0056] S1. The pulverized material is smoothed by the blade edge of the scraper 1300 until the material has a thickness of 1mm and then sent to the magnetic separation device. The magnetic separation device includes a permanent magnet roller 100. The speed of the permanent magnet roller 100 is 0.05m / s. When the permanent magnet roller 100 is above, the magnetic iron powder will be firmly absorbed on the roller until the belt and the roller are separated as the permanent magnet roller 100 turns to the lowest point, and the iron powder is also separated from the permanent magnet roller 100 and falls into the lower left. The square iron powder hopper 200, under the action of gravity and centrifugal force, the remaining material falls off tangentially from the permanent magnet roller 100 and enters the electrostatic separation device at the lower right;

[0057]...

Example Embodiment

[0059] Example 2

[0060] The steps of Embodiment 2 are the same as those of Embodiment 1, except that the rotational speed of the permanent magnet roller 100 in step S1 is 0.1 m / s. The voltage in step 2 is 20kV, the rotation speed of the roller electrode 500 is 800r / min, the linear speed of the conveyor belt 720 in step S3 is 0.2m / s, and the amplitude of the driven wheel 710 is 0.12m / s.

Example Embodiment

[0061] Example 3

[0062] The steps of Embodiment 3 are the same as those of Embodiment 1, except that the rotational speed of the permanent magnet roller 100 in step S1 is 0.2 m / s. The voltage in step 2 is 30kV, the rotation speed of the roller electrode 500 is 1000r / min, the linear speed of the conveyor belt 720 in step S3 is 0.2m / s, and the amplitude of the driven wheel 710 is 0.15m.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap