Charging control system and control method

A charging control method and charging control technology, applied in the field of automobiles, can solve problems such as reducing system reliability, increasing single vehicle cost, and vehicle failure to start, so as to reduce system complexity, improve system reliability, and avoid failure to start.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

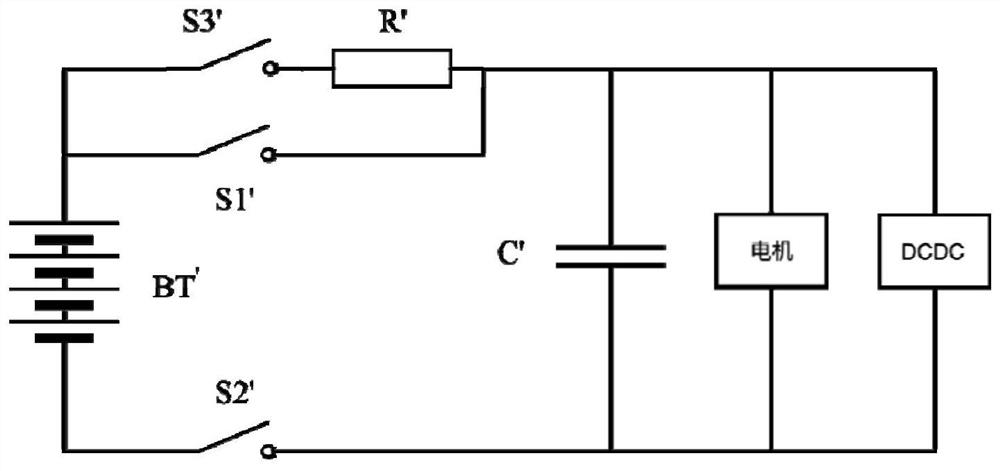

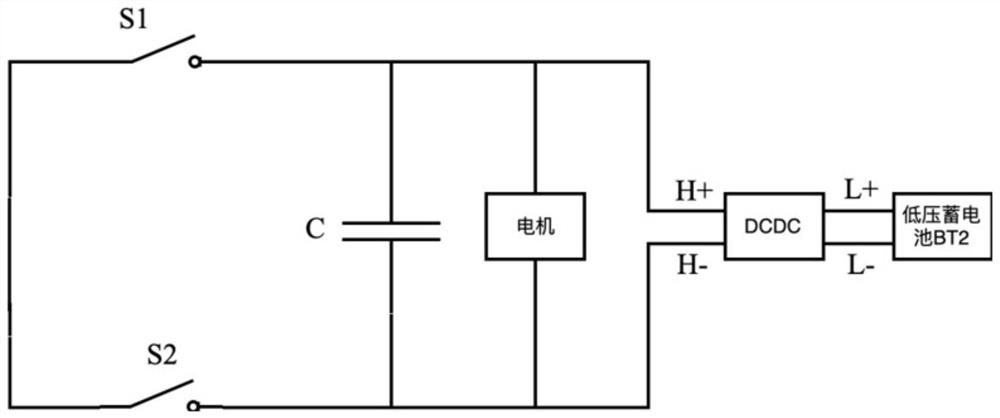

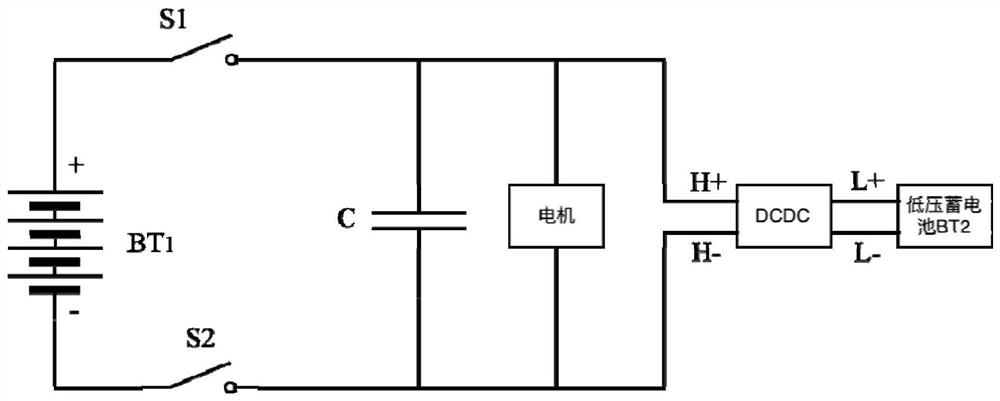

[0043] DETAILED DESCRIPTION OF THE DRAWINGS will be further described below.

[0044] It is readily understood that, in accordance with the technical solution of the present invention, various structural methods and implementations of the general technicians can be replaced with each other in the spirit of the present invention. Therefore, the following detailed description and the accompanying drawings are merely illustrative of the technical solutions of the present invention, and it is not considered to be limited or limited to the present invention.

[0045] In this specification, or may be mentioned, lower, left, right, front, rear, front, back, top, bottom, is defined relative to the configuration shown in each of the drawings, they are The relative concept is therefore possible to perform correspondingly variation depending on the different positions thereof. Therefore, these or other orientations should not be interpreted as limiting terms.

[0046] like figure 2 , The prese...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap