Preparation and application of an environmentally friendly and low-cost superhydrophobic powder material

A powder material, super-hydrophobic technology, applied in coatings and other directions, can solve the problems of inconvenient promotion and large-scale practical application, weak combination of micro-nano structure and substrate, and high cost of super-hydrophobic surface preparation, so as to reduce the preparation cost and shorten the Reaction time, the effect of increasing the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

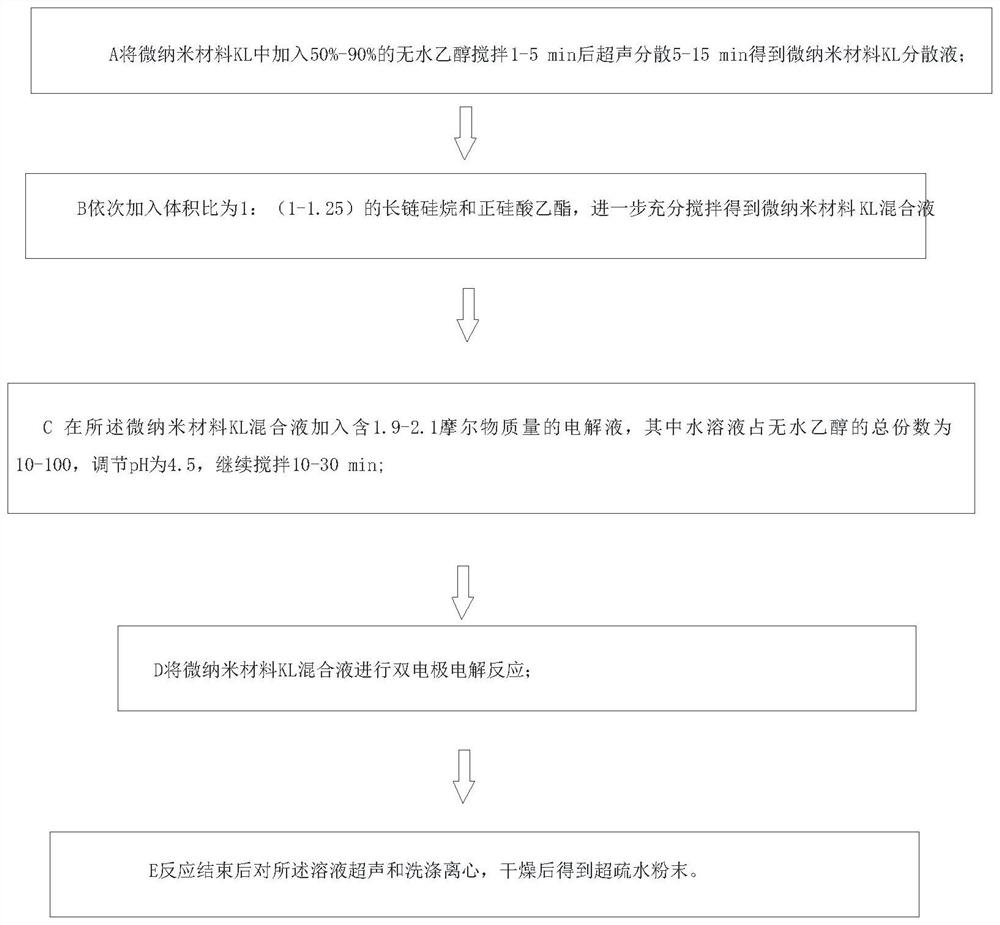

Method used

Image

Examples

Embodiment 1

[0037] Measure 70ml of absolute ethanol into a 150ml electrolytic cell, add 2.25g of micro-nano material KL, first magnetically stir for 1min, and then ultrasonic for 10min; the stirring time is to fully mix the micro-nano material KL and absolute ethanol, and the ultrasonic is to allow The micro-nano material KL is fully dispersed.

[0038] Add 2.5ml tetraethyl orthosilicate and 2.0ml long-chain silane 1 in sequence, and stir for 5 minutes;

[0039] Then add 30ml NaNO3 (0.67M) aqueous solution, adjust the pH with glacial acetic acid, and continue to stir for 30 minutes; the sodium nitrate aqueous solution mainly acts as an electrolyte, so potassium nitrate, potassium chloride, etc. can be used instead.

[0040] Use electrode 1 (1.5cm×1.5cm) as the anode, electrode 2 (4.5cm×2.25cm) as the cathode, and the distance between the electrodes is 4.5cm. Use a DC power supply (Huatai Power Supply HAP03-100) to react at a constant voltage of 30.0V for 90min with the assistance of stirr...

Embodiment 2

[0045] Measure 80ml of absolute ethanol into a 150ml electrolytic cell, add 2.25g of micro-nano material KL, first magnetically stir for 1min, then ultrasonic for 10min;

[0046] Add 2.5ml tetraethyl orthosilicate and 2.0ml long-chain silane 1 in sequence, and stir for 5 minutes;

[0047] Then add 30ml NaNO3 (0.67M) aqueous solution, use glacial acetic acid to adjust the pH, and continue to stir for 30min;

[0048] Use electrode 1 (1.5cm×1.5cm) as the anode, electrode 2 (4.5cm×2.25cm) as the cathode, and the distance between the electrodes is 4.5cm. Use a DC power supply (Huatai Power Supply HAP03-100) to react at a constant voltage of 40.0V for 90min with the assistance of stirring , sonicate for 5 minutes after the reaction;

[0049] Utilize centrifuge to separate 5min under 8000rpm, use absolute ethanol to wash three times;

[0050] The white matter was collected and dried at 60°C for 6h.

[0051] From the above experimental procedures, it can be seen that the difference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com