Preparation method and application of polymer microspheres for protein separation analysis based on core-shell structure

A protein separation and core-shell structure technology, applied in the field of polymer materials, can solve the problems of low separation efficiency, non-uniform particles, poor pressure resistance of chromatographic packing, etc., and achieve the effects of good rigidity, remarkable technical effect and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

[0021]Specific implementation case 1:

[0022]The present invention will be further explained below in conjunction with specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and not to limit the scope of the present invention. In addition, it should be understood that after reading the content taught in the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also belong to the protection scope of the claims of this application.

Example Embodiment

[0023]Example 1

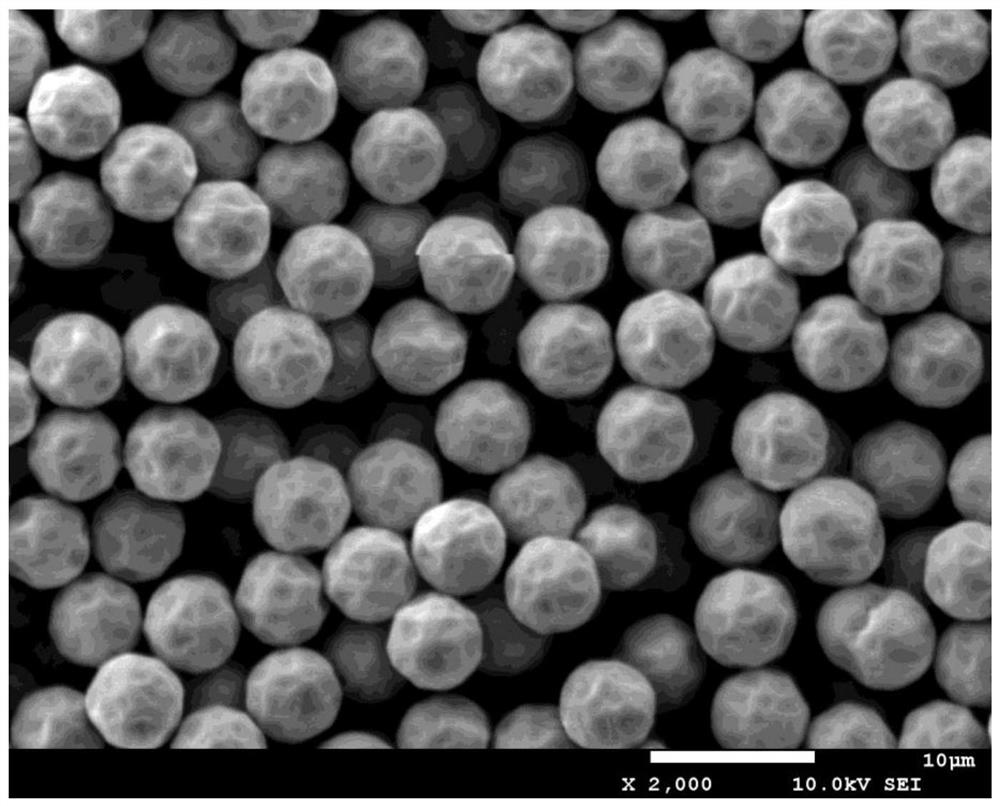

[0024]Take 10 ml of newly distilled divinylbenzene, add it to 200 ml of acetonitrile, stir for 30 minutes under nitrogen protection, then add 0.2 g of azobisisobutyronitrile (AIBN), heat to 70°C, and react for 5 hours. Then 3 ml of glycidyl methacrylate (GMA) was added, and the polymerization reaction was continued for 1 hour. The obtained polymer microspheres were thoroughly washed with acetonitrile.

[0025]The above-mentioned microspheres were dispersed in 100 ml of 0.1M (0.1mol / L) dilute sulfuric acid, and the reaction was stirred at 90°C for 2 hours. The obtained microspheres were washed with water and dried. The air-dried microspheres were dispersed in 0.4M (0.1mol / L) NaOH, 10 ml of epichlorohydrin was added, and the reaction was stirred at 50°C for 6 hours. The obtained microspheres were thoroughly washed with ethanol and water.

[0026]The above microspheres were dispersed in a 2% dextran solution, the pH was adjusted to 12.5, and the reaction was carried out at roo...

Example

[0029]Specific implementation case 2:

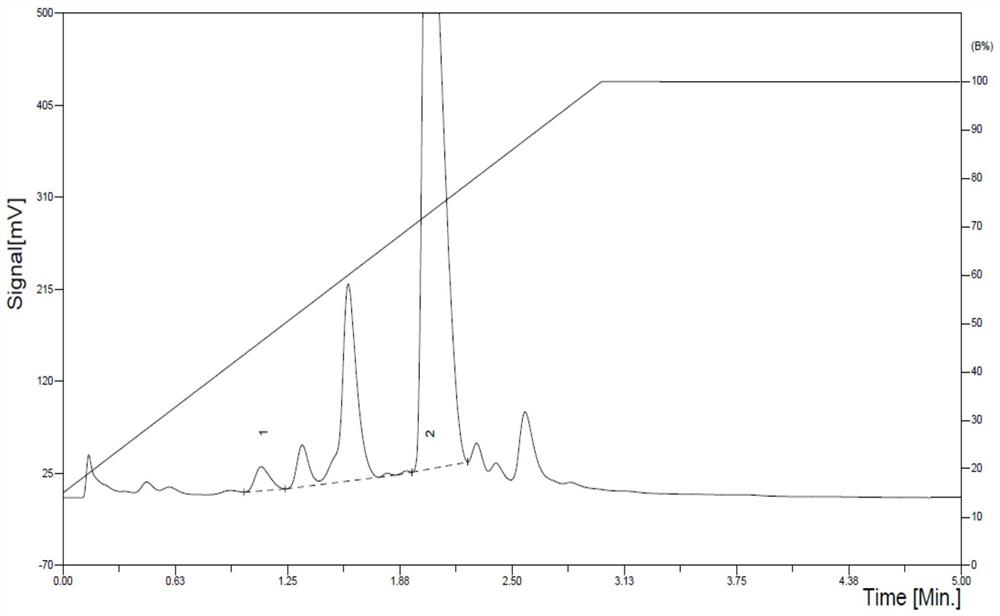

[0030]The sulfate radical-containing core-shell structure cation exchange polymer microspheres obtained in Example 1 were dispersed in water, and then packed on a 4.6×30 mm chromatographic column for protein separation analysis test. A typical HPLC chromatogram of glycosylated hemoglobin in blood is as followsfigure 2Shown.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap