Sunlight fermentation hydrogen production apparatus

A technology of sunlight and installation tank, applied in biochemical cleaning device, enzymology/microbiology device, bioreactor/fermenter combination, etc., can solve the problems of manual cleaning, low fermentation efficiency, affecting light transmission effect, etc. , to achieve the effect of flexible and convenient use, improved fermentation efficiency, and good light transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

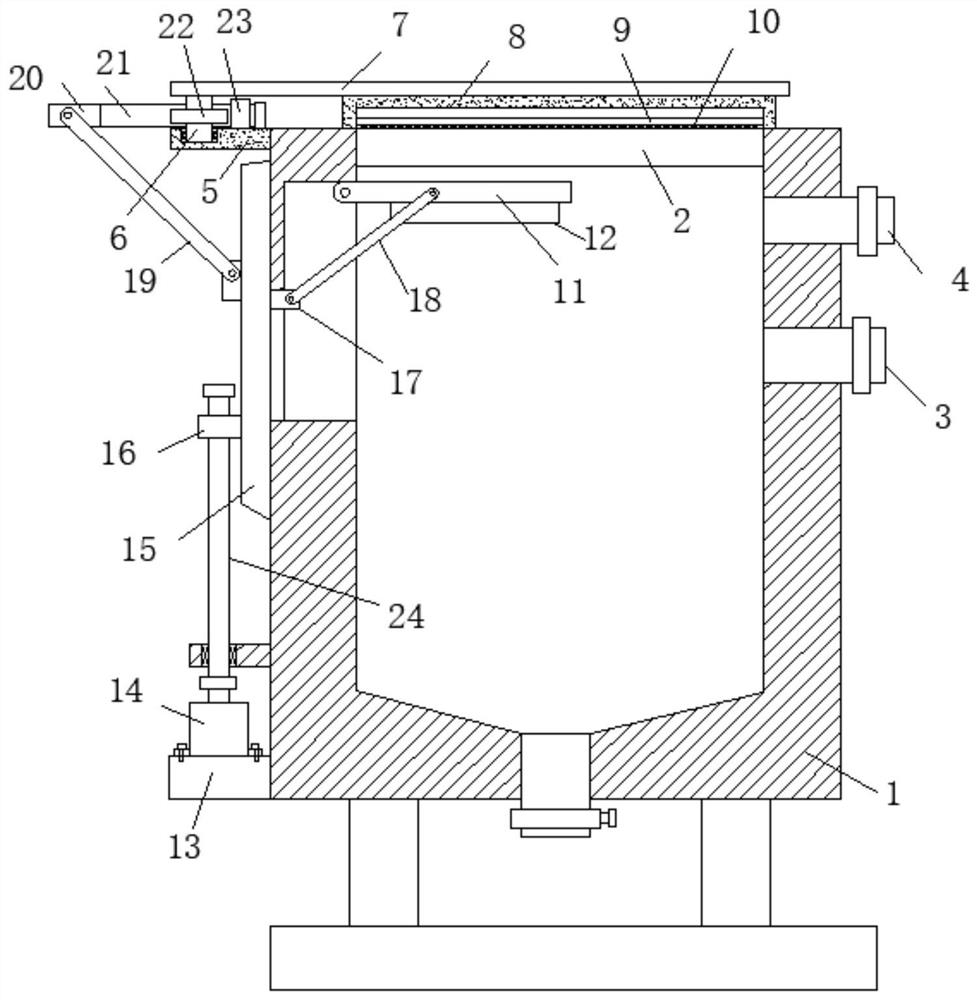

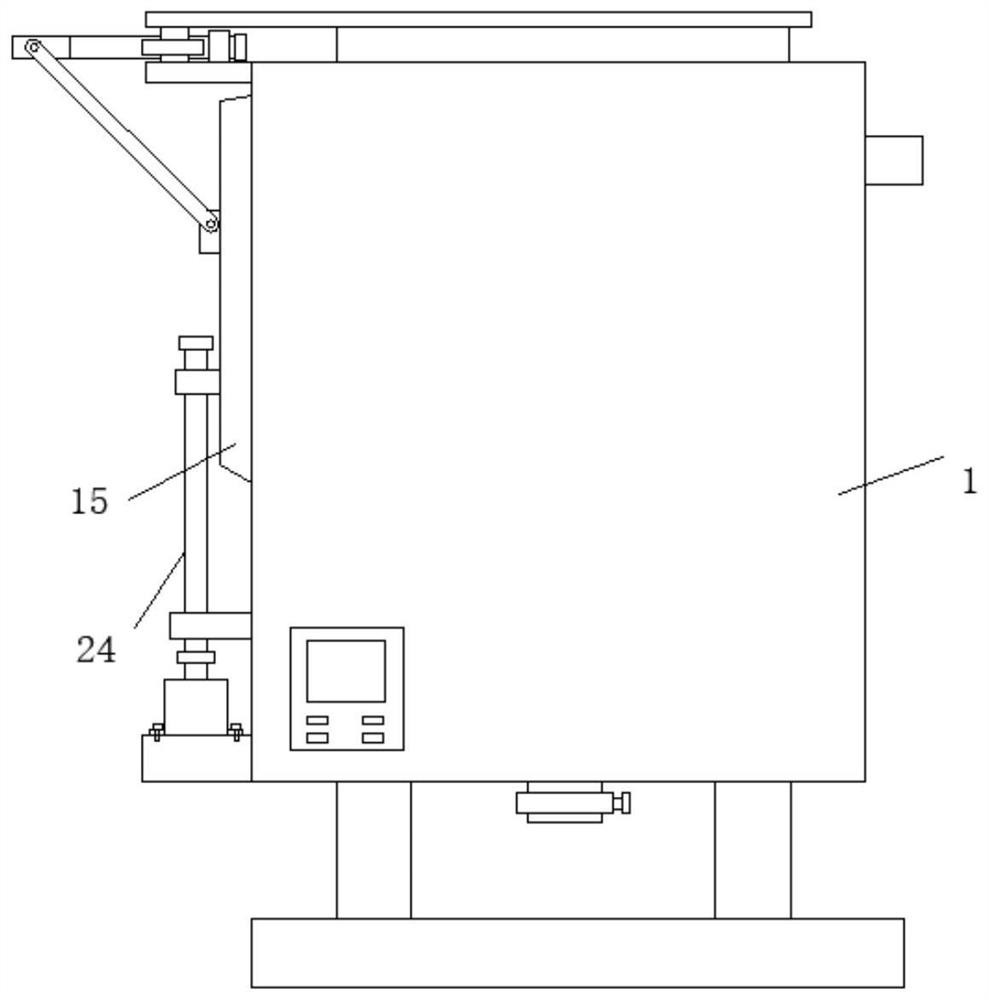

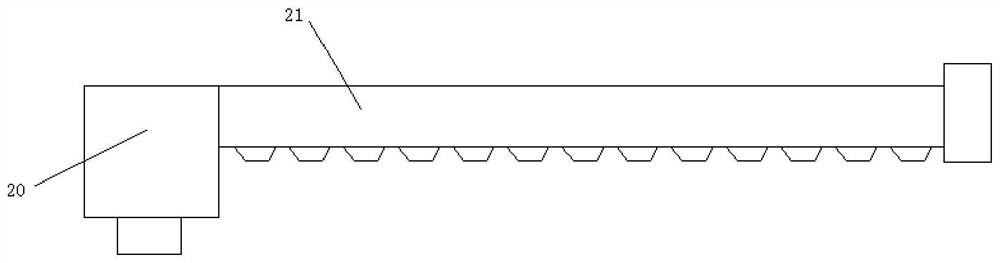

[0019] refer to Figure 1-3 , a solar fermentation hydrogen production device, comprising a fermentation box 1, the top surface of the fermentation box 1 is embedded with a light-transmitting plate 2, and the left inner wall of the upper end of the fermentation box 1 is provided with an installation groove. The left side of 1 is provided with a vertical chute communicating with the installation groove, and one end of the installation plate 11 is rotatably connected in the installation groove, the bottom of the installation plate 11 is fixed with a lighting lamp 12, and the left side of the lower end of the fermentation box 1 is fixed with a fixed Seat 13, the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com