A cable tie assembly

A component and belt technology, applied in the direction of flexible and slender components, packaging, sustainable packaging industry, etc., can solve the problem of heavy belt weight, belt bendability, belt and lock nut locking reliability Balance, high material cost and other issues, to achieve the effect of reducing material cost, balancing locking reliability, and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

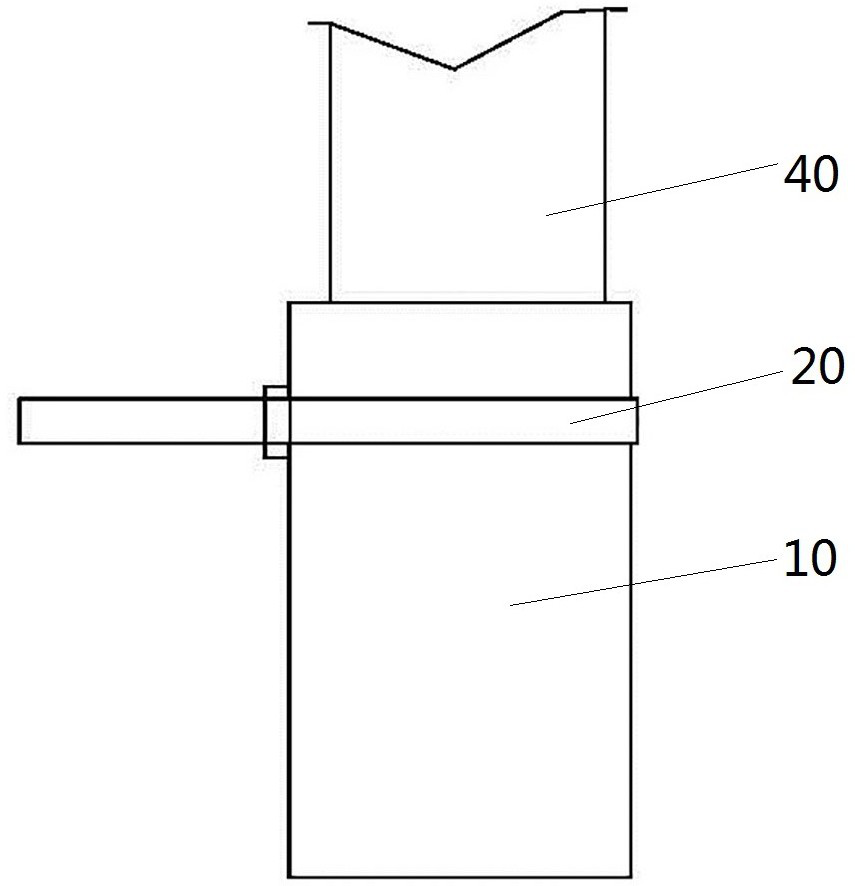

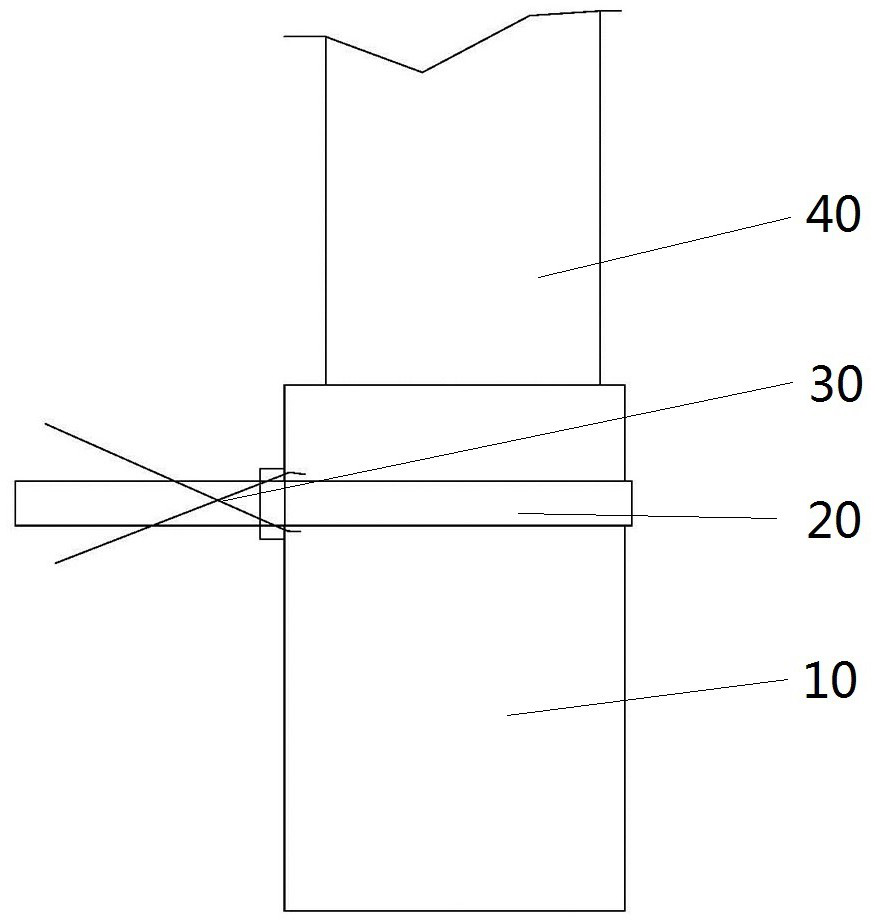

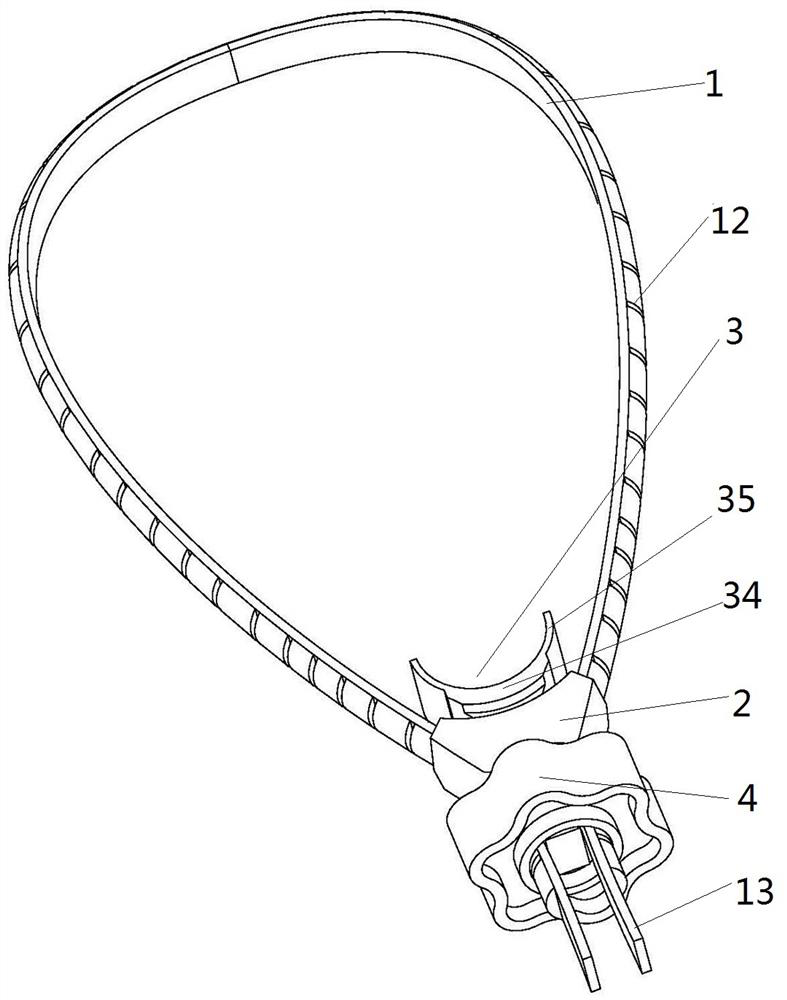

[0050] like image 3 and Figure 4 As shown, the strap assembly includes a strap body 1, a housing 2, a support column 3 and a locking nut 4, such as Figure 5 As shown, the belt body 1 includes an abutting surface 11 and a circular arc surface, the abutting surfaces 11 are close to each other when the belt body 1 is bent, and the circular arc surface is provided with screw teeth 12 . The two parts of the belt body 1 in an overlapping state after being bent are referred to as the bending part 13 , the overlapping direction of the two bending parts 13 is the left-right direction, and the bending direction of the belt body 1 is the rear. like Image 6 As shown, the locking nut 4 is provided with a threaded hole 41 , and the threaded hole 41 is used for threaded connection with the bent portion 13 of the belt body 1 . like Figure 7 and Figure 8 As shown, the casing 2 is provided with a front and rear through hole 21, such as Figure 9 and Figure 10 As shown, the support...

specific Embodiment 2

[0063] The main difference between it and the above-mentioned embodiment 1 is that the support head of the belt body in the above-mentioned embodiment 1 is provided with an insertion hole, the belt body passes through the insertion hole, and then the mating surface of the bent part and the belt body of the support column are supported. face fit. In this embodiment, there is no insertion hole on the support head of the belt body, and the belt body is directly bypassed from the left and right corresponding sides of the support head of the belt body.

specific Embodiment 3

[0065] The main difference between it and the above-mentioned Embodiment 1 is that the belt support head in the above-mentioned Embodiment 1 is composed of a shell and a support column arranged separately. The belt support head in this embodiment is an integral structure as a whole, that is, the housing and the support column in the above-mentioned Embodiment 1 are integral structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com