Air energy hot water module machine

A modular machine, air energy technology, applied in the direction of space heating and ventilation, heat pump, refrigerator, etc., can solve the problems of low energy utilization rate, inability to recycle return water, single function and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

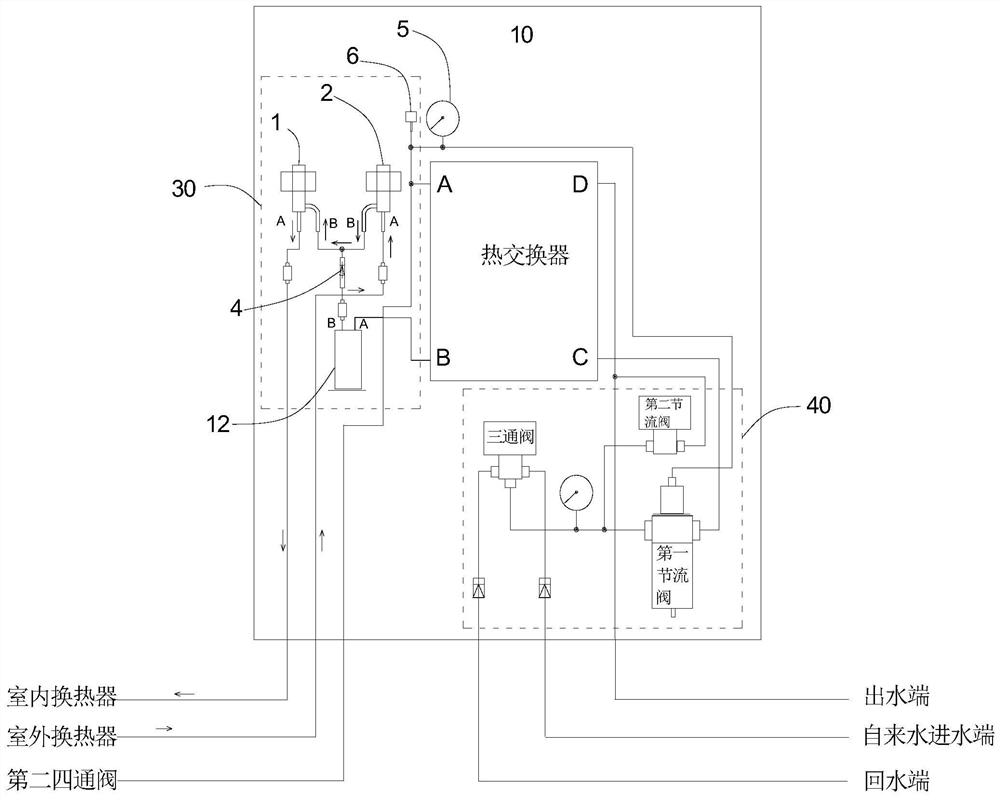

[0049] (1) The refrigerant circulation part 30 and the external part 20

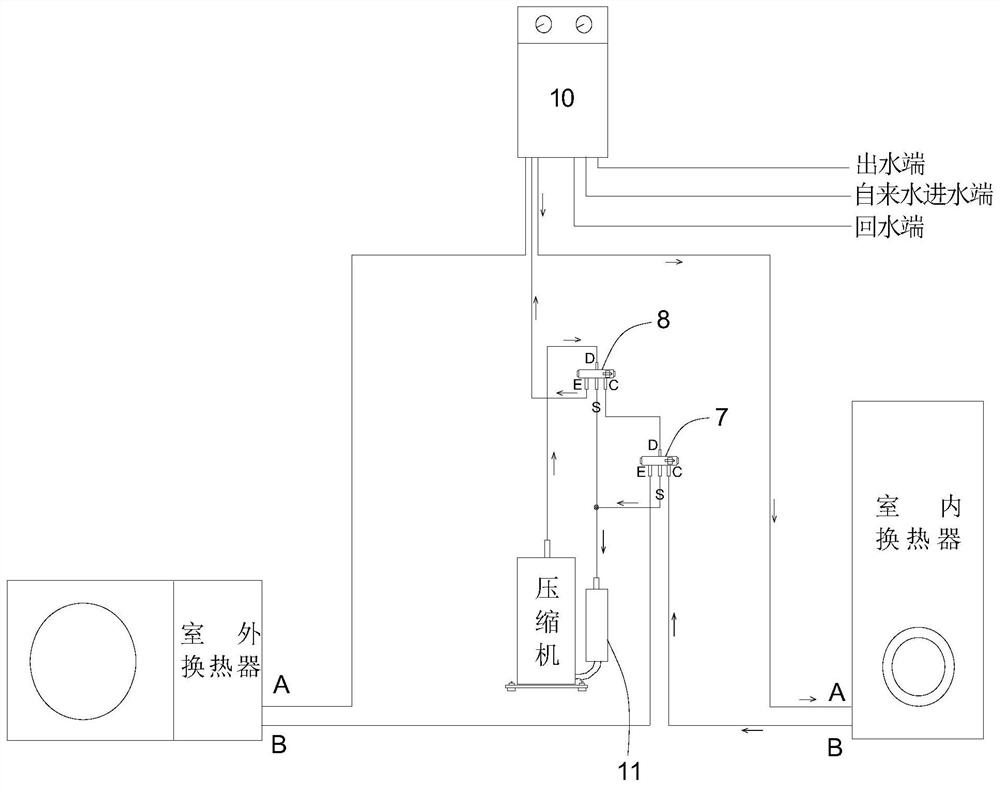

[0050] refer to Figure 1-2 , the refrigerant cycle part 30 includes a first expansion valve 1 , a second expansion valve 2 , an accumulator 12 and a check valve 4 . The external part 20 includes an indoor heat exchanger, an outdoor heat exchanger, a four-way valve, a gas-liquid separator 11 and a compressor, and the four-way valve includes a first four-way valve 7 and a second four-way valve 8 .

[0051] The indoor heat exchanger, first expansion valve 1, second expansion valve 2, outdoor heat exchanger, first four-way valve 7, gas-liquid separator 11, compressor, second four-way valve 8, heat exchanger, The liquid reservoir 12 is connected to the one-way valve 4 in sequence, and the one-way valve 4 is also connected to the first expansion valve 1 and the second expansion valve 2, and the first four-way valve 7 is connected to the indoor heat exchanger and the second expansion valve respectively. Four...

Embodiment 2

[0077] (1) The refrigerant circulation part 30 and the external part 20

[0078] refer to figure 1 and 11 , this embodiment is generally the same as Embodiment 1, the refrigerant cycle part 30 also includes a third expansion valve 3, and there is no need to set a one-way valve 4, which can further increase the working efficiency, especially in the defrosting mode, it can realize rapid defrosting .

[0079] The refrigerant circulation part 30 includes a first expansion valve 1 , a second expansion valve 2 , a third expansion valve 3 and an accumulator 12 . The external part 20 includes an outdoor heat exchanger, a four-way valve, a gas-liquid separator 11 and a compressor, and the four-way valve includes a first four-way valve 7 and a second four-way valve 8 .

[0080] The indoor heat exchanger, first expansion valve 1, second expansion valve 2, third expansion valve 3, outdoor heat exchanger, first four-way valve 7, gas-liquid separator 11, compressor, second four-way valve...

Embodiment 3

[0104] Compared with Embodiments 1 and 2, this embodiment has the same air energy hot water module machine 10, but the external part 20 is different, and its structure is simpler. The external part 20 is only equipped with a four-way valve 9, and the four-way valve is specifically the third The four-way valve 9 has simplified functions and does not have a heating function.

[0105] (1) The refrigerant circulation part 30 and the external part 20

[0106] The refrigerant circulation part 30 includes a first expansion valve 1 , a second expansion valve 2 , an accumulator 12 and a check valve 4 . The external part 20 includes an indoor heat exchanger, an outdoor heat exchanger, a third four-way valve 9, a gas-liquid separator 11 and a compressor.

[0107] The indoor heat exchanger, the first expansion valve 1, the second expansion valve 2, the outdoor heat exchanger, the third four-way valve 9, the gas-liquid separator 11, the compressor, the heat exchanger, the liquid receiver ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com