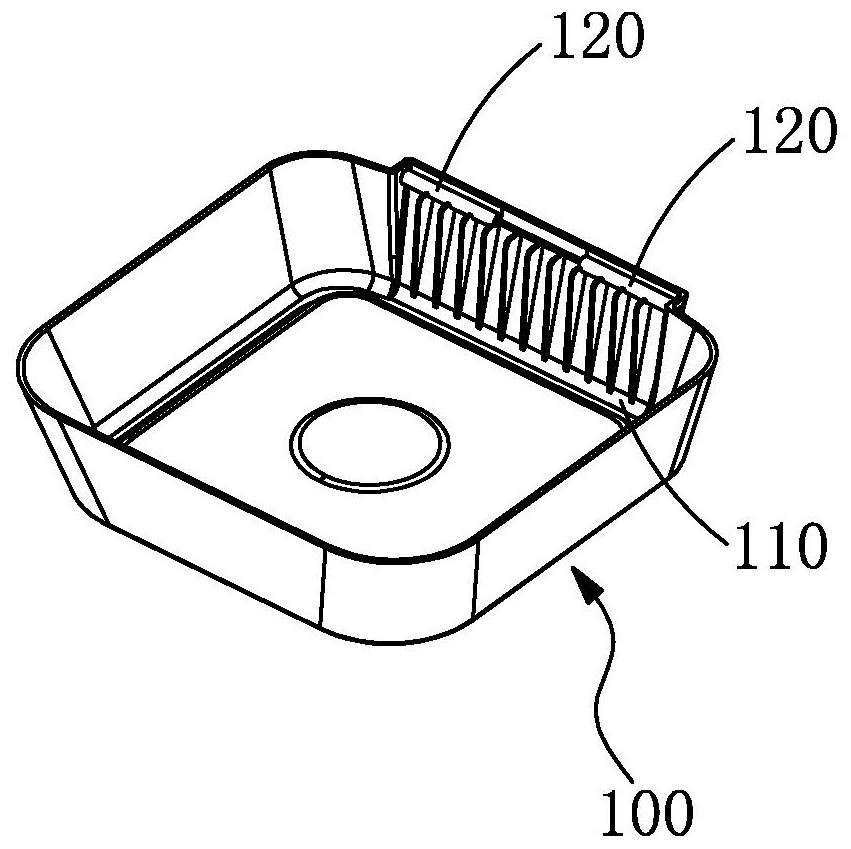

A sliding block delay mechanism and mold

A sliding block and mold technology, applied in the field of molds, can solve the problems of the sliding block subsidence, the thickness of the product, and the difficulty in adjusting the break, so as to prevent the sliding block submersion from sinking, easy processing and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

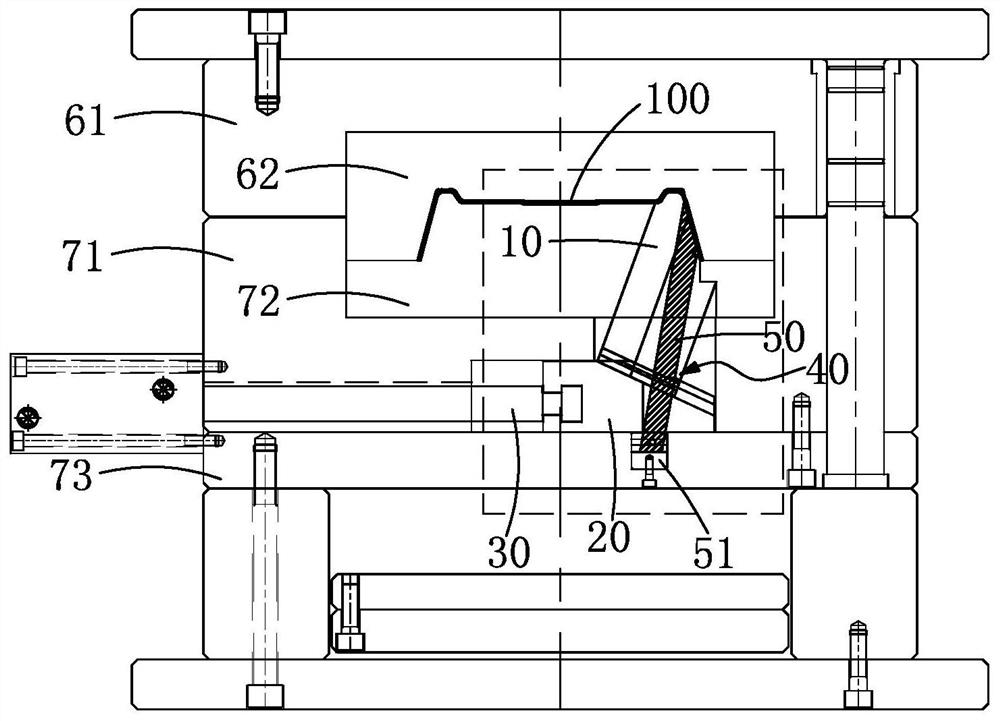

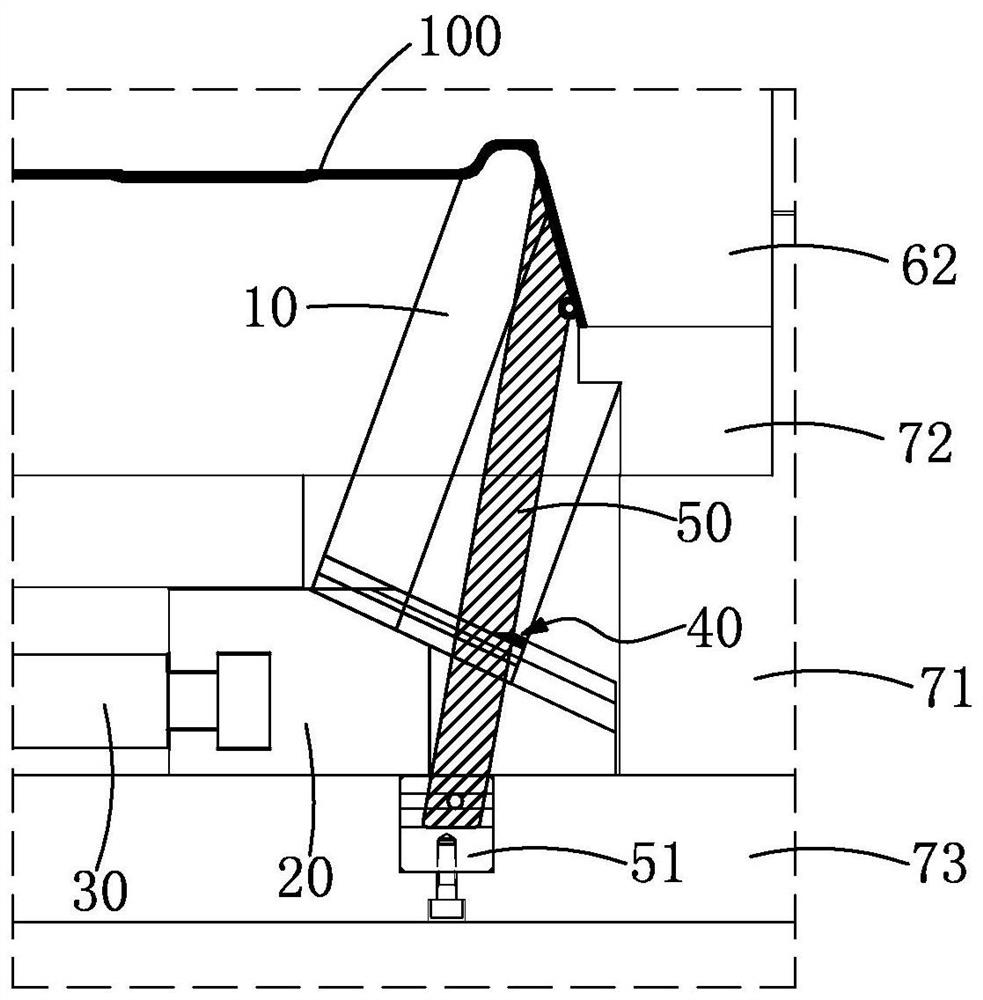

[0026] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

[0027] like Figure 2-11 As shown, a slider delay mechanism includes a slider entry 10, a slider body 20 and an oil cylinder 30; one end of the slider entry 10 is involved in forming the product, and the other end is slidably connected with the slider body 20; the piston of the oil cylinder 30 The end is connected with the slider body 20; the connection between the slider body 20 and the slider inlet 10 is provided with a delay structure 40, so that the slider inlet 10 can delay the withdrawal of the product along the withdrawal direction.

[0028] Specifically, the slider insert 10 and the slider body 20 are slidably connected by a sliding rail. One of the slider inserts 10 and the slider body 20 is provided with a T-shaped groove, and the other is provided with a T-shaped protrusion. The T-shaped groove and the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com