Preparation method of nitenpyram sustained-release tablets

A technology for nitenpyram and sustained-release tablets, which is applied in the field of preparation of nitenpyram sustained-release tablets, can solve the problems of special preparation equipment, high preparation equipment requirements, slow preparation process, etc., and achieves good drug stability, The effect of good color and large drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

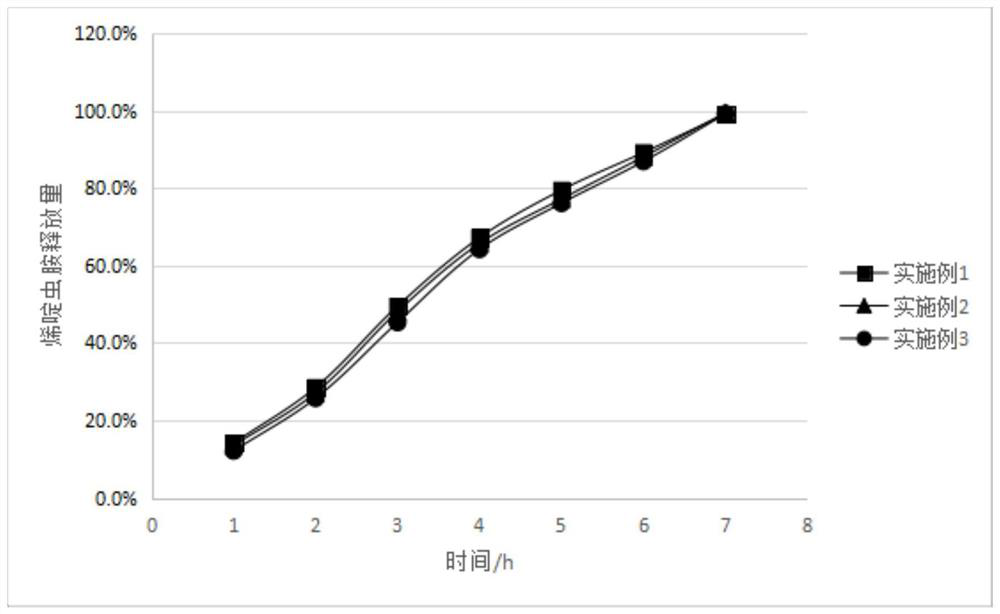

[0033]Example 1

[0034]

[0035]The preparation method includes the following steps:

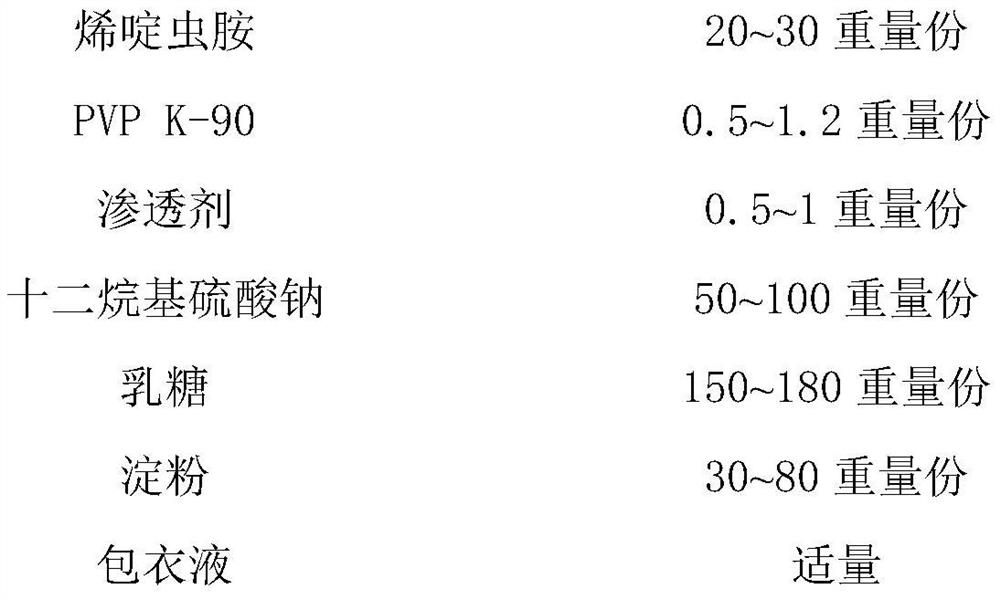

[0036](1) Preparation of tablet core: Mix nitenpyram and PVP K-90, add penetrant, sieving, dry at 50°C, add sodium lauryl sulfate, lactose, starch, and press to obtain nitenpyram Amine core

[0037](2) Preparation of coating solution: add magnesium stearate, talc, and titanium dioxide to the water in order to prepare an aqueous dispersion, and add hypromellose and polyethylene glycol 4000 to the aqueous dispersion; prepare a coating liquid;

[0038](3) Place the nitenpyram tablet core in a coating solution at 30°C for coating treatment, and then dry at 50°C to obtain the nitenpyram sustained-release tablet.

[0039]As mentioned above, the penetrant is a mixture of azone lauryl, sodium chloride and glycerin, and the mass ratio of the azone lauryl, sodium chloride and glycerol is 4:1:10.

[0040]As mentioned above, the mass ratio of hydroxypropyl cellulose to polyethylene glycol 4000 in the coating liquid is 3:1.

Example Embodiment

[0041]Example 2

[0042]

[0043]The preparation method includes the following steps:

[0044](1) Preparation of tablet core: Mix nitenpyram and PVP K-90, add penetrant, sieving, dry at 50°C, add sodium lauryl sulfate, lactose, starch, and press to obtain nitenpyram Amine core

[0045](2) Preparation of coating solution: add magnesium stearate, talc, and titanium dioxide to the water in order to prepare an aqueous dispersion, and add hypromellose and polyethylene glycol 4000 to the aqueous dispersion; prepare a coating liquid;

[0046](3) Place the nitenpyram tablet core in a coating solution at 30°C for coating treatment, and then dry at 50°C to obtain the nitenpyram sustained-release tablet.

[0047]As mentioned above, the penetrating agent is a mixture of azone lauryl, sodium chloride and glycerin, and the mass ratio of azone lauryl, sodium chloride and glycerol is 3:2:12.

[0048]As mentioned above, the mass ratio of hydroxypropylcellulose to polyethylene glycol 4000 in the coating liquid is 4:1.

Example Embodiment

[0049]Example 3

[0050]

[0051]The preparation method includes the following steps:

[0052](1) Preparation of tablet core: Mix nitenpyram and PVP K-90, add penetrant, sieving, dry at 50°C, add sodium lauryl sulfate, lactose, starch, and press to obtain nitenpyram Amine core

[0053](2) Preparation of coating solution: add magnesium stearate, talc, and titanium dioxide to the water in order to prepare an aqueous dispersion, and add hypromellose and polyethylene glycol 4000 to the aqueous dispersion; prepare a coating liquid;

[0054](3) Place the nitenpyram tablet core in a coating solution at 30°C for coating treatment, and then dry at 50°C to obtain the nitenpyram sustained-release tablet.

[0055]As mentioned above, the penetrant is a mixture of azone lauryl, sodium chloride and glycerin, and the mass ratio of the azone lauryl, sodium chloride and glycerol is 5:1:10.

[0056]As mentioned above, the mass ratio of hydroxypropyl cellulose to polyethylene glycol 4000 in the coating liquid is 5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap