Device for treating waste gas generated after household garbage incineration and purification method thereof

A technology for domestic waste incineration and waste gas treatment devices, which is applied to chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of affecting the processing work, not being able to filter large particles of waste residue, and the adsorption and dehumidification components are easily blocked by adsorption and dehumidification. Speed up gas circulation, good filtration effect, and improve purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

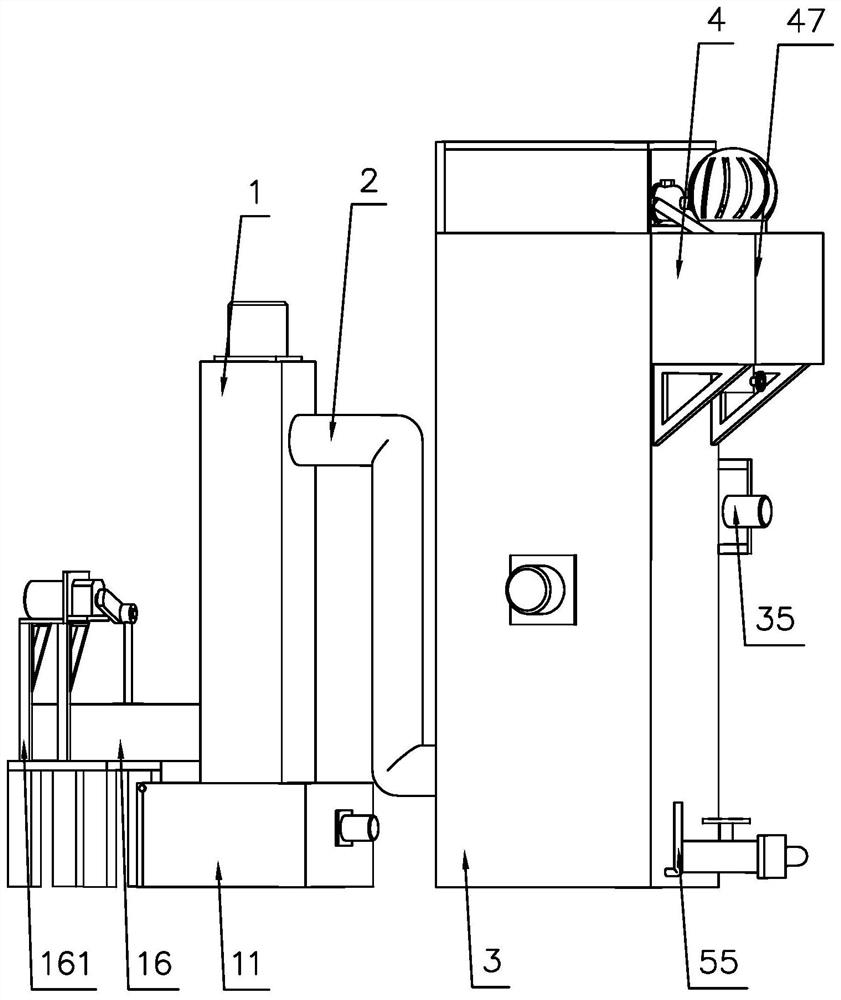

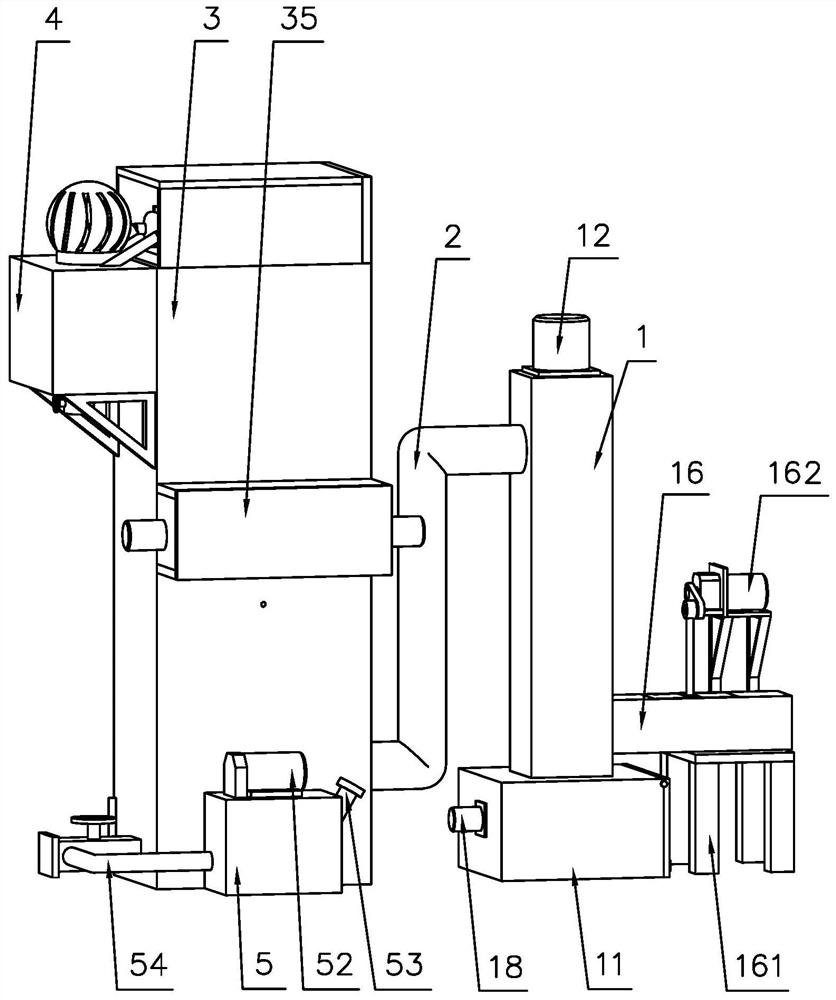

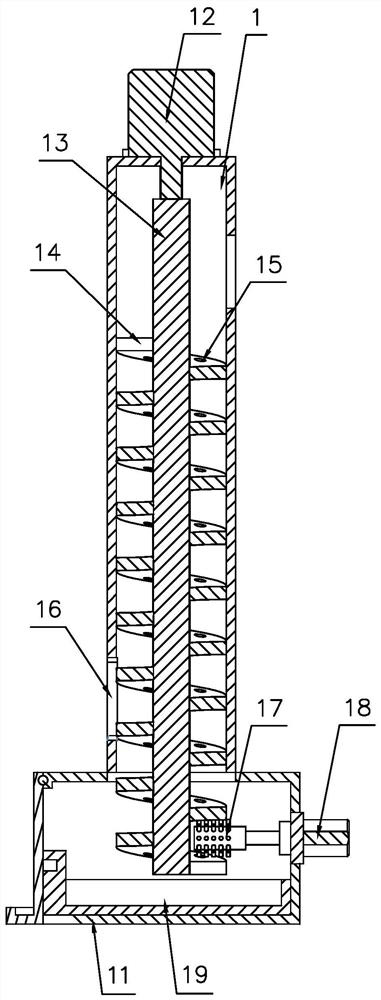

[0048]To facilitate the understanding of those skilled in the art, the following is attachedFigure 1-13, The technical scheme of the present invention is further explained in detail.

[0049]An exhaust gas treatment device after incineration of domestic garbage includes an exhaust gas preliminary filtering mechanism 1, a gas pipeline 2, an exhaust gas washing mechanism 3, a purification exhaust mechanism 4, and a liquid supply tank 5. The gas pipeline 2, the gas pipeline 2 is provided with an exhaust gas washing mechanism 3 on one side, the exhaust gas washing mechanism 3 is provided with a purification exhaust mechanism 4, and the other side of the exhaust gas washing mechanism 3 is provided with a liquid supply tank 5, and the exhaust gas is initially The filter mechanism 1 is connected to the exhaust gas washing mechanism 3 through the gas pipeline 2, the exhaust gas washing mechanism 3 is in communication with the purification exhaust mechanism 4, and the exhaust gas washing mechan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap