Full-automatic ton bag packaging machine

A fully automatic, packaging machine technology, applied in packaging machines, packaging, packaging protection and other directions, can solve the problems of inconvenient forklift transportation, affecting hook lifting slings, affecting bag support operations, etc., achieving significant economic and social benefits, reducing The labor intensity of workers and the effect of convenient forklift transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0050] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below.

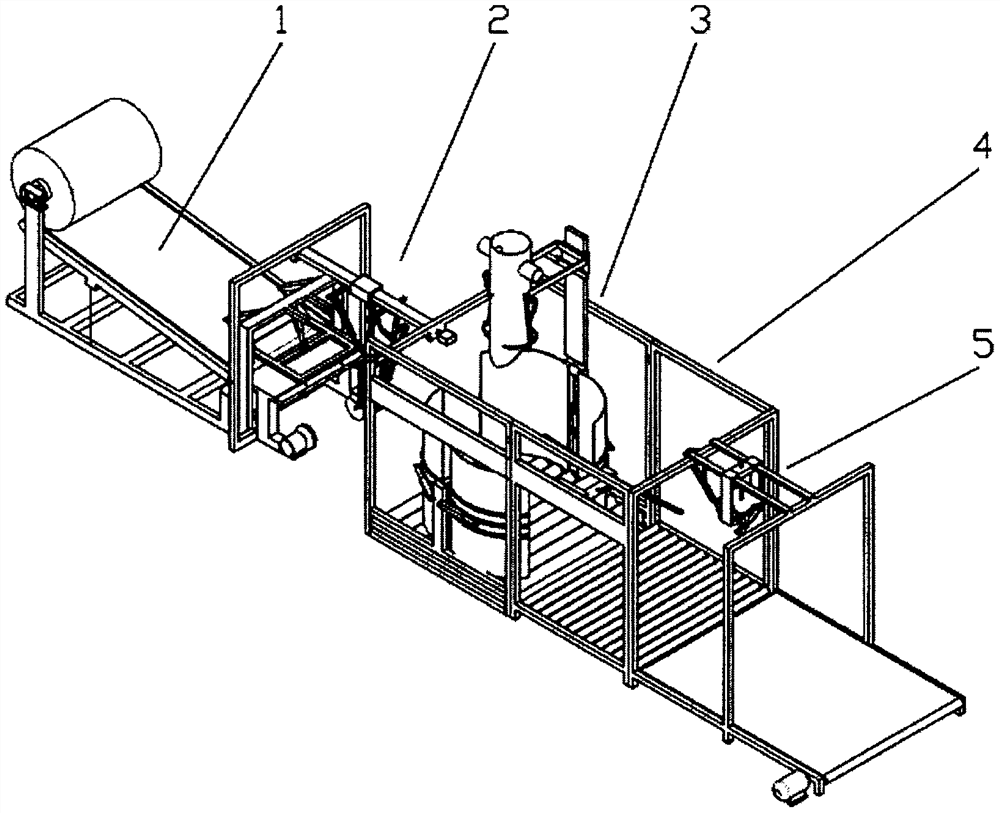

[0051] The present invention provides a fully automatic ton bag packaging machine, such as figure 1 As shown, it includes a bag transfer mechanism 1, a bag holding mechanism 2, a feeding mechanism 3, a bag sealing mechanism 4 and a conveying mechanism 5. The bag transfer mechanism 1 is located on one side of the unloading mechanism 3, and the bag holding mechanism 2 is located on the bag transfer mechanism. Between the mechanism 1 and the unloading mechanism 3 , the conveying mechanism 5 is located on the other side of the unloading mechanism 3 , and the bag sealing mechanism 4 is located between the unloading mechanism 3 and the conveying mechanism 5 .

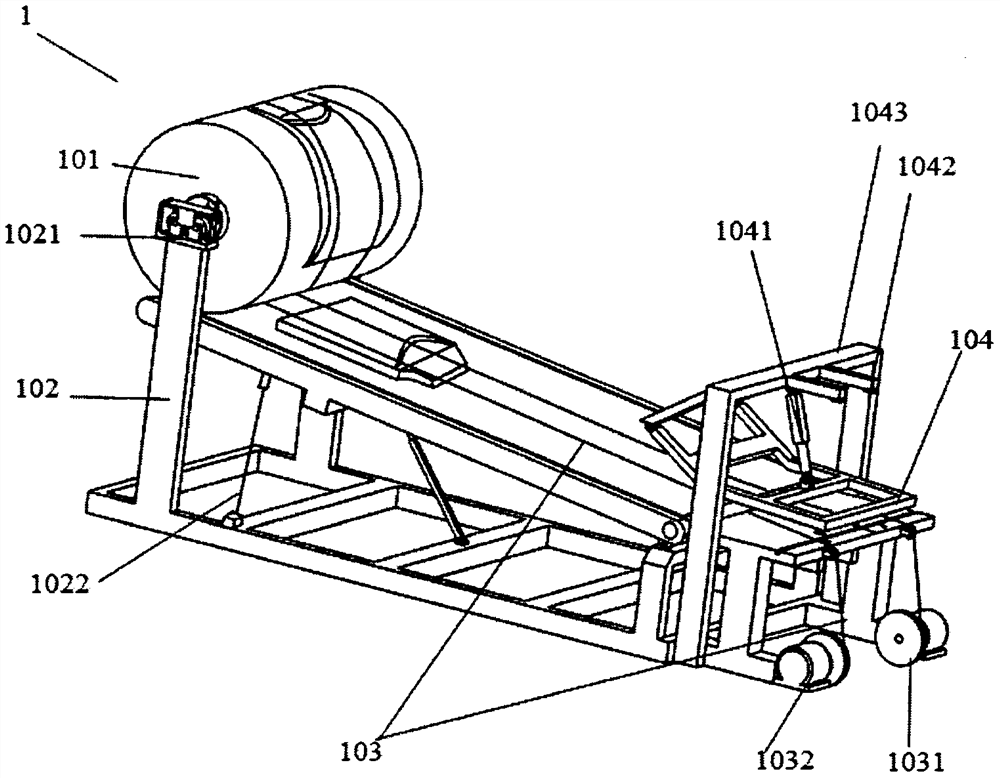

[0052] Specifically, as figure 2 As shown, the bag transfer mechanism 1 includes a bag roll 101 , a conveyor bed 102 , a belt 103 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap