A kind of high-performance protective coating and preparation method thereof

A protective coating and high-performance technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems that affect coating performance, poor overall performance of coatings, and large specific surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

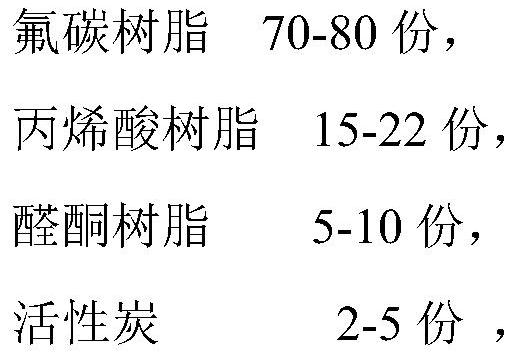

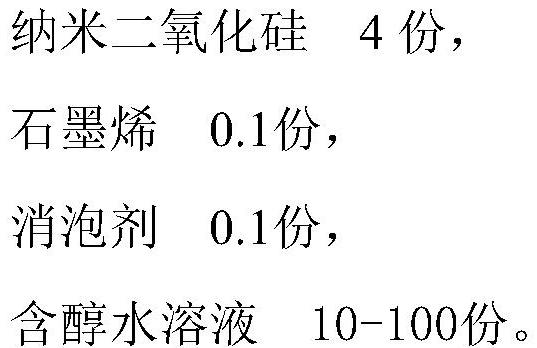

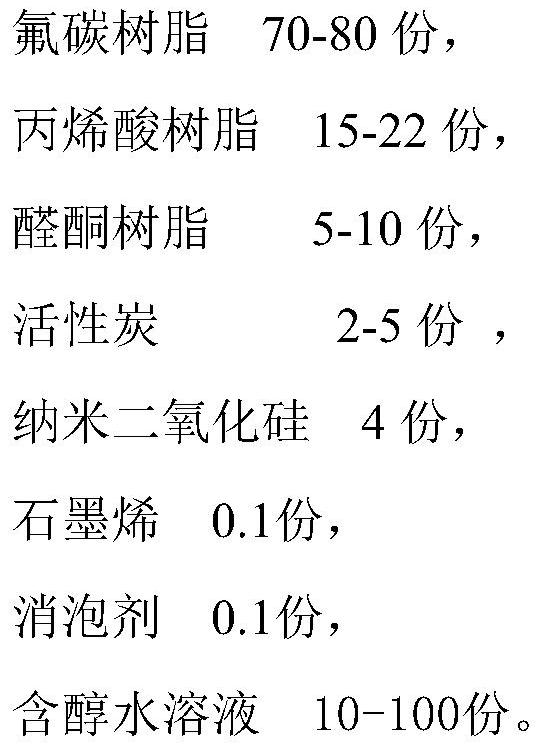

[0042] Further, the preparation method comprises the following steps:

[0043] Preparation of nano-silica-modified acrylic resin: disperse half the weight of nano-silica in alcohol-containing aqueous solution, then add acrylic resin, react at 60-90°C to obtain nano-silica-modified acrylic resin;

[0044] Mixing 1: Fully mix the remaining weight of nano-silica and activated carbon to obtain Mixture 1;

[0045] Mixing 2: mixing the fluorocarbon resin and graphene to disperse the graphene evenly to obtain a mixture 2;

[0046]Add the above-mentioned nano-silica modified acrylic resin, aldehyde and ketone resin and mixture 1 to the above-mentioned mixture 2, then add defoamer, mix well to make the dispersion uniform, and the product is obtained.

[0047] The present invention also provides a preparation method of the high-performance protective coating, which is characterized in that it comprises the following steps:

[0048] Preparation of nano-silica-modified acrylic resin: di...

Embodiment 1

[0052] Embodiment 1: the preparation of high-performance protective coating

[0053] Raw materials: see Table 1.

[0054] Preparation method: Preparation of nano-silica-modified acrylic resin: disperse half the weight of nano-silica in alcohol-containing aqueous solution, then add acrylic resin, and react at 60-90°C to obtain nano-silica-modified acrylic resin;

[0055] Mixing 1: Fully mix the remaining weight of nano-silica and activated carbon to obtain Mixture 1;

[0056] Mixing 2: mixing the fluorocarbon resin and graphene to disperse the graphene evenly to obtain a mixture 2;

[0057] Add the above-mentioned nano-silica modified acrylic resin, aldehyde and ketone resin and mixture 1 to the above-mentioned mixture 2, then add defoamer, mix well to make the dispersion uniform, and the product is obtained.

[0058] Table 1 each embodiment and the consumption table of comparative example (calculated by weight)

[0059]

Embodiment 2

[0060] Embodiment 2: the preparation of high-performance protective coating

[0061] Raw materials: see Table 1.

[0062] Preparation method: with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com