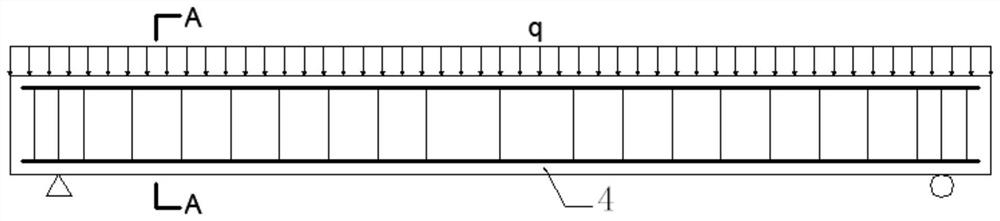

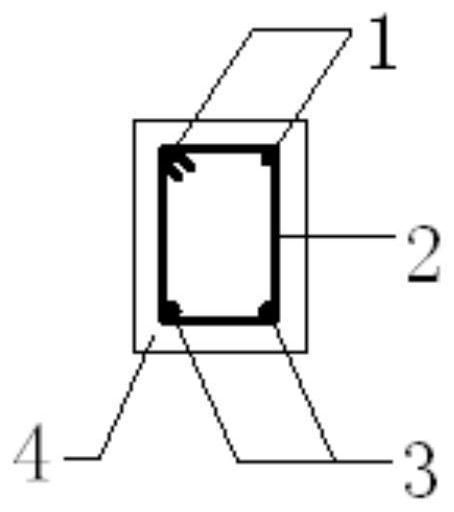

Rubber aggregate concrete beam for FRP bar structure

A technology of rubber aggregates and concrete beams, applied in truss structures, joists, girders, etc., can solve problems such as difficulty in meeting specification requirements and comfort requirements, low crack resistance, etc., to reduce black pollution and improve ultimate bearing capacity strength, improving ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024]Examples:

[0025](1) Control the strength grade of rubber aggregate concrete. Material strength is the key to structural design, and fine control of material strength is conducive to the reliability and safety of structural design. GB 50010-2010 "Specification for Design of Concrete Structures" stipulates that when the strength grade of steel bars in reinforced concrete beams is HRB400, the concrete strength grade shall not be lower than C25. Therefore, it is necessary to find suitable methods to ensure the preparation of rubber aggregate concrete with the same strength level as ordinary concrete.

[0026](2) Determine the mixing method of rubber aggregate. There are two general design methods for the mix ratio of rubber aggregate concrete: the first is the equal volume of rubber particles to replace fine aggregate, the equal volume of rubber particles to replace coarse aggregate, and the equal volume of rubber particles to replace part of fine aggregate and part of coarse aggregat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap