A pipe fitting crimping device

A technology of pipe fittings and components, which is applied in the direction of lifting devices, tubular objects, household appliances, etc., can solve the problems of unstable crimping device position, poor crimping effect, and difficulty in placing pipe fittings, and achieve good crimping effect, extended service life, and easy operation Labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following specific examples are only explanations of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications without creative contribution to the present embodiment as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

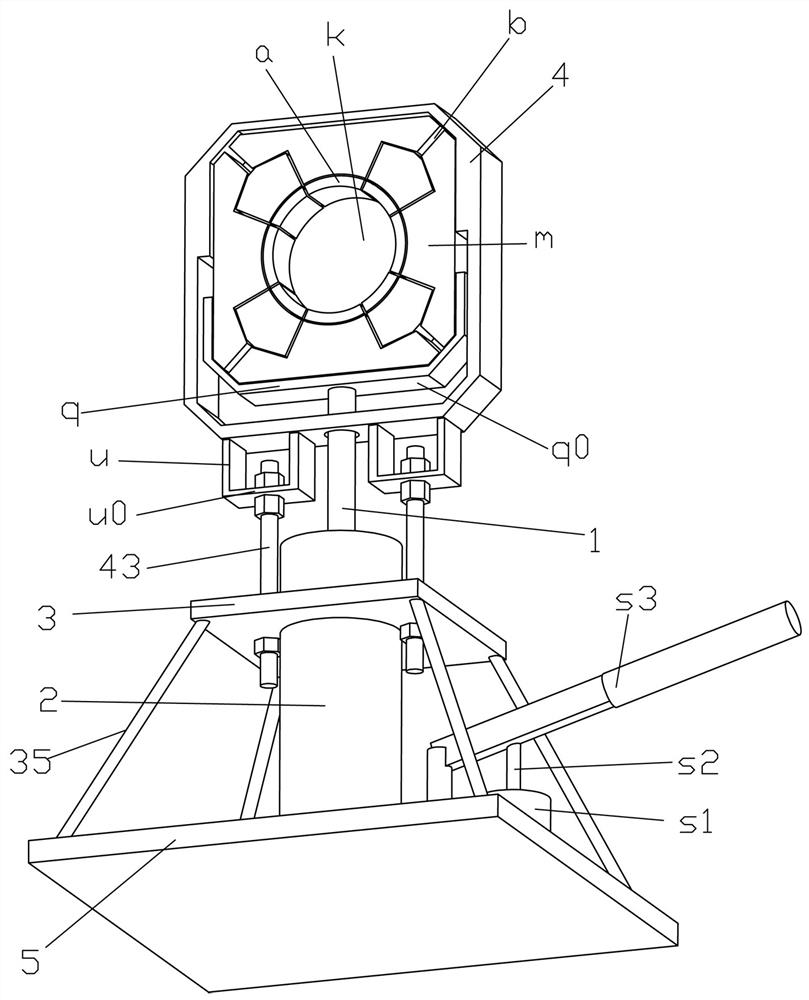

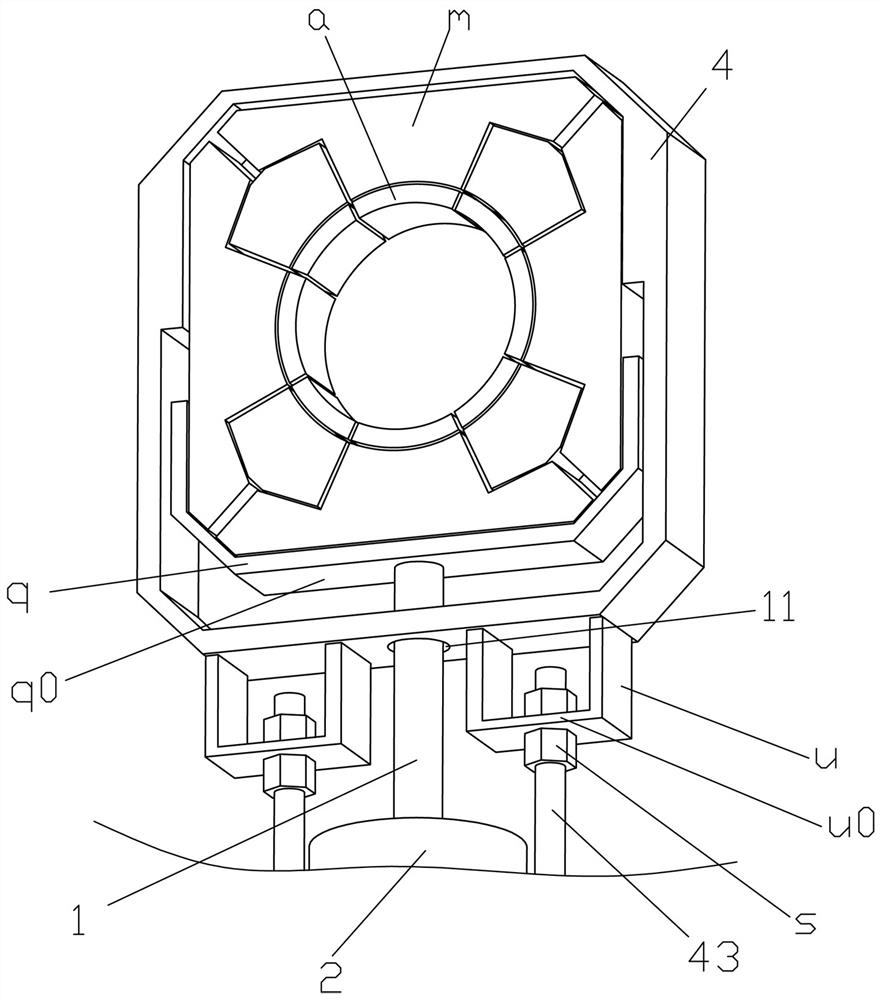

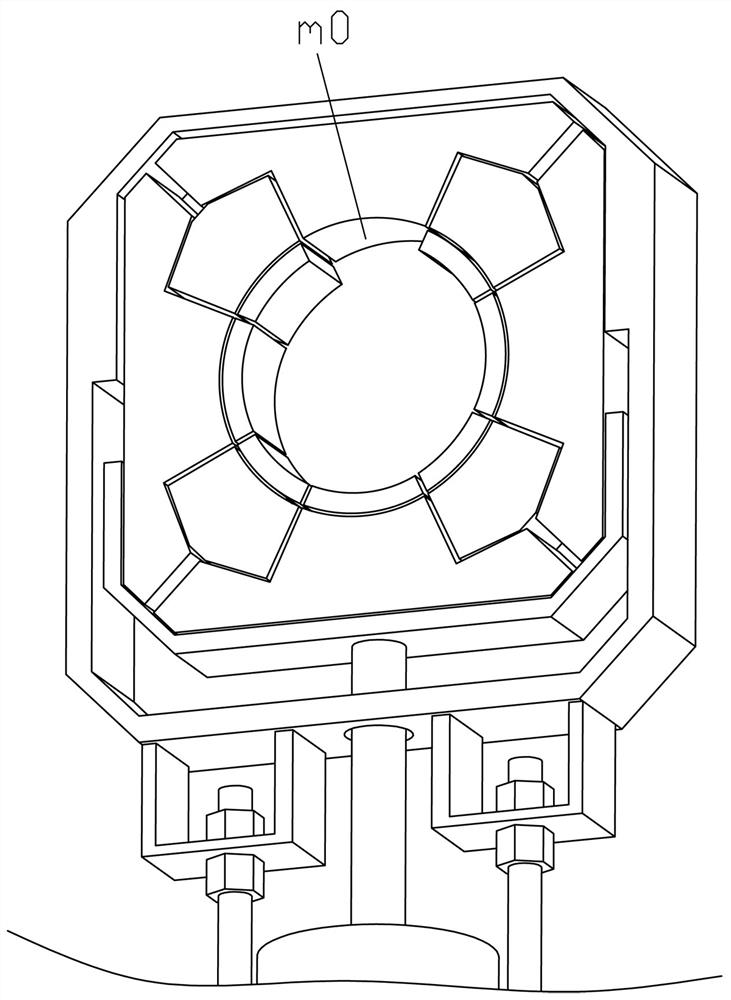

[0026] Examples such as Figure 1-5As shown, a pipe fitting crimping device includes a vertical hydraulic jack and a pipe fitting crimping assembly that is driven upward by the power output piston rod 1 of the hydraulic jack that extends up and down in an upright shape to crimp the pipe. The hydraulic jack applied for is a standing type. This kind of hydraulic jack only needs to adopt the existing structure, but it must be noted that it needs to be a standing type, or an upright type. The power output piston rod 1 is also the jack. The large piston, the power output hydraulic cylinder...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap