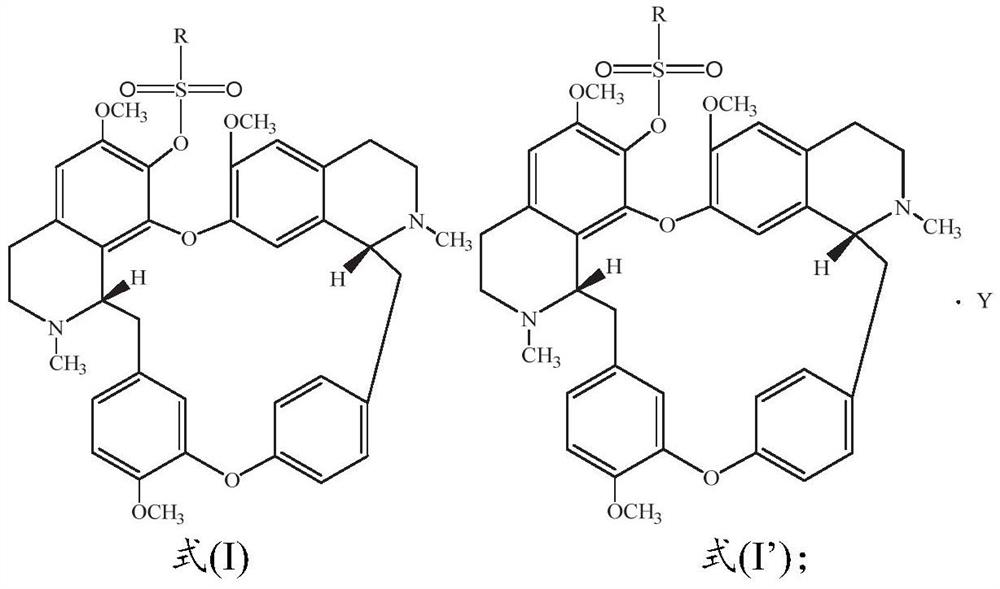

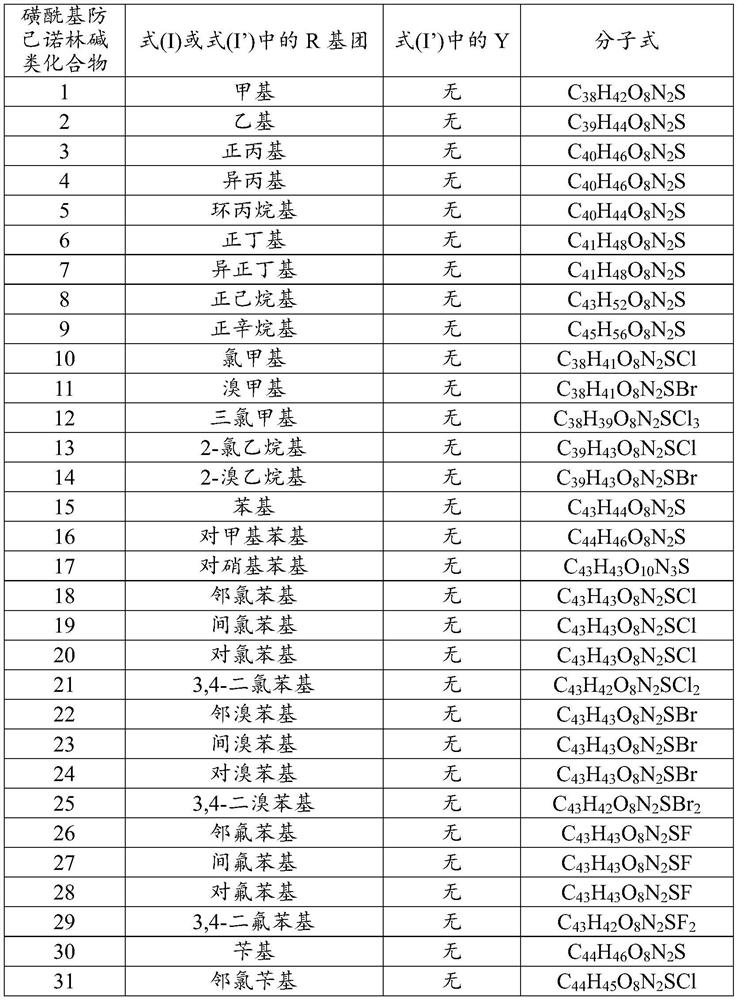

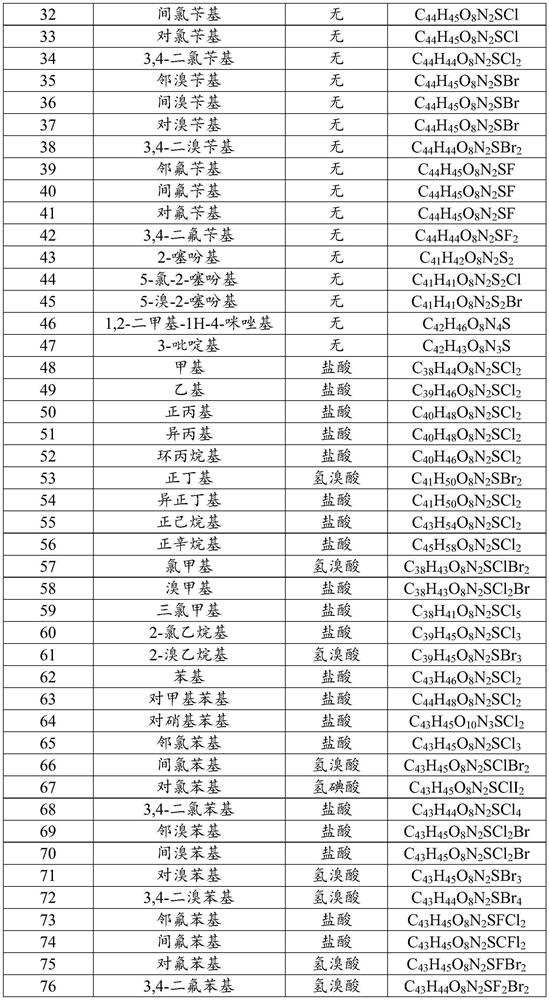

Sulfonyl tetragonolin base compound and preparation method and application thereof

A technology of fangchinoline base and compound, which is applied in the field of medicine and can solve the problems of small application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Dissolve 100.0 mg of tetrandrine base (about 0.18 mmol) in 3 mL of dichloromethane, add it to a two-necked flask filled with argon, and place it in a cold well with a temperature controlled to 0 °C, add it and dissolve it in 2 mL under magnetic stirring. 66.5 mg (about 0.72 mmol) of triethylamine in dichloromethane, after mixing for 1 h, 31.0 mg (about 0.27 mmol) of methanesulfonyl chloride was added to react, and the reaction was followed by TLC. After the reaction, the reaction solution was concentrated and purified by passing through a neutral alumina column. The eluent was dichloromethane: methanol (eluted at 120:1 and 80:1, respectively), and separated and purified to obtain a white powdery product 117.5 mg (about 0.17 mmol), melting point: 208.1-209.9°C, yield 94.4%. Product analysis and characterization: 1 H NMR (400MHz, CDCl 3 )δ7.40(dd,J=8.2,1.9Hz,1H),7.15(dd,J=8.2,2.5Hz,1H),6.85(d,J=7.7Hz,2H),6.81(dd,J=8.3 ,2.5Hz,1H),6.56(s,1H),6.46(s,1H),6.40(s,1H),6.33(dd...

Embodiment 2

[0057] Dissolve 100.0 mg of tetrandrine base (about 0.18 mmol) in 3 mL of chloroform, add it to a two-necked flask filled with argon, and place it in a cold well whose temperature is controlled to -20°C. Under magnetic stirring, add the solvent. After mixing 5.0 mg (about 0.20 mmol) of NaH in 2 mL of chloroform for 1 h, 23.2 mg (about 0.18 mmol) of ethylsulfonyl chloride was added to react, and the reaction was followed by TLC. After the reaction was completed, the reaction solution was concentrated and purified by passing through a neutral alumina column. The eluent was dichloromethane: methanol (eluted at 120:1 and 80:1, respectively), and separated and purified to obtain a white powdery product 113.6 mg (about 0.162 mmol), melting point: 205.5-207.2°C, yield 90.0%. Product analysis and characterization: 1 H NMR (400MHz, CDCl 3 )δ7.36(dd,J=8.2,1.9Hz,1H),7.14(dd,J=8.2,2.4Hz,1H),6.82(dt,J=8.3,5.3Hz,3H),6.51(d,J =16.7Hz,2H),6.42-6.30(m,2H),6.04(s,1H),3.92(s,3H),3.88-3.81(m,1...

Embodiment 3

[0059] Dissolve 100.0 mg of tetrandrine base (about 0.18 mmol) in 10 mL of dichloromethane, add it to a two-necked flask filled with argon, and place it in a cold well controlled to a temperature of 0 °C, add it and dissolve it in 2 mL under stirring. 62.0 mg (about 0.72 mmol) of piperidine in dichloromethane, after mixing for 1 h, 25.6 mg (about 0.20 mmol) of n-propylsulfonyl chloride was added to react, and the reaction was tracked by TLC. After the reaction, the reaction solution was concentrated to 1 / 3 of the volume of the original solution, crystallized in a cold well at 0°C for more than 4 hours, quickly filtered, and vacuum-dried below 50°C to obtain 115.9 mg (about 0.162 mmol) of white powdery product, Melting point: 204.9-206.5°C, yield 90.0%. Product analysis and characterization: 1 H NMR (400MHz, CDCl 3 )δ7.29(dd,J=8.2,1.9Hz,1H),7.06(dd,J=8.1,2.4Hz,1H),6.74(dt,J=8.3,5.4Hz,3H),6.43(d,J =14.0Hz,2H),6.36-6.19(m,2H),5.96(s,1H),3.84(s,3H),3.76(dd,J=11.1,5.3Hz,0H),3.73...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap