CAM cutting tool path overload analyzing and processing method and system

A technology of analysis processing and cutting tool, applied in the field of CAM cutting, it can solve the problems of insufficient cutting overload processing and equipment collision, and achieve the effect of improving processing effect and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0051]In order to make the purpose, technical solutions and advantages of the present application clearer, the technical solutions of the present application will be described in detail below. Obviously, the described embodiments are only a part of the embodiments of the present application, rather than all the embodiments. Based on the embodiments in this application, all other implementations obtained by a person of ordinary skill in the art without creative work shall fall within the protection scope of this application.

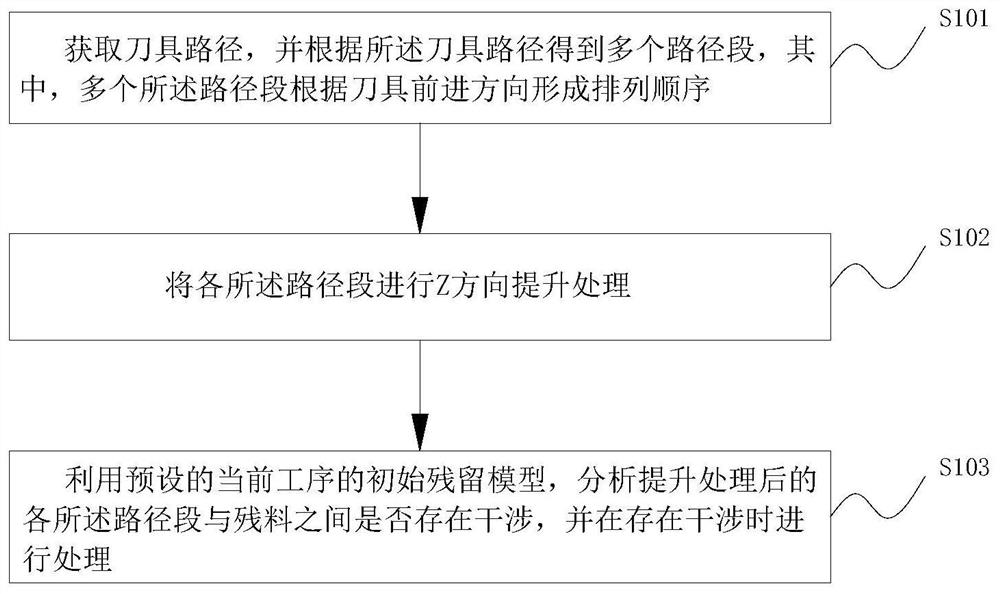

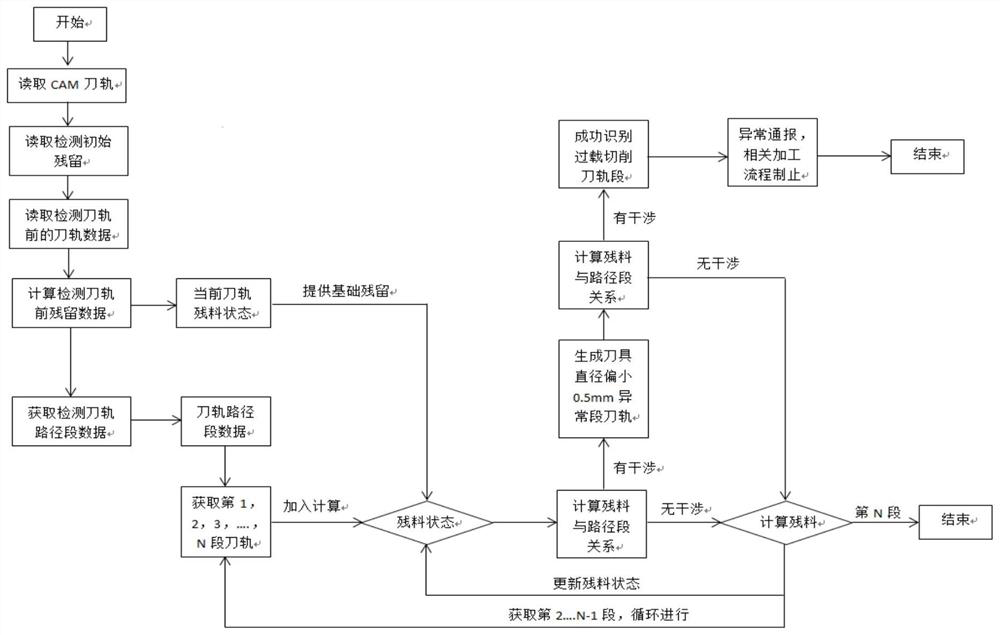

[0052]Seefigure 1 ,figure 1 It is a flow chart showing a method for analyzing and processing CAM cutting tool rail overload according to an exemplary embodiment, such asfigure 1 As shown, the method for analyzing and processing the CAM cutting tool path overload includes the following steps:

[0053]Step S101: Obtain a tool path, and obtain multiple path segments according to the tool path, wherein the multiple path segments form an arrangement sequence according to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap